A method and device for treating hypophosphorous and phosphorous in wastewater

A technology for treating wastewater and hypophosphorus, which is applied in chemical instruments and methods, metallurgical wastewater treatment, water/sewage treatment, etc., can solve the problems of low efficiency of advanced oxidation technology, and achieve low production cost, good treatment effect and easy production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

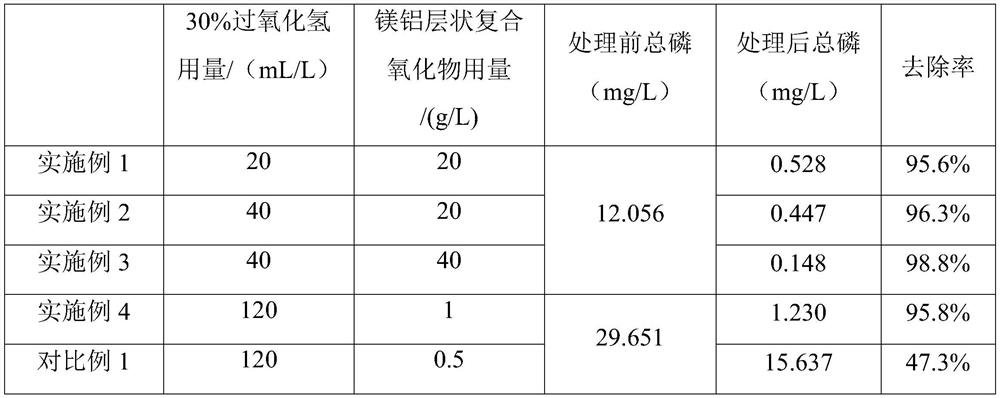

Embodiment 1

[0029] A method for treating hypophosphorous and phosphorous in waste water, comprising the following steps:

[0030] (1) Place the magnesium aluminum hydrotalcite in a crucible, calcinate it in a muffle furnace at 400°C for 4 hours, and grind it through a 200-mesh sieve after cooling to obtain a magnesium aluminum layered composite oxide;

[0031] (2) inject 20ml / L 30% hydrogen peroxide solution into the oxidation reaction pool (in waste water, hypophosphorus concentration 7.5mg / L, phosphorous acid concentration 2.5mg / L, nickel ion concentration is about 10mg / L waste water) and Stir, and transfer the wastewater to the adsorption reaction pool after 10 minutes of sufficient pre-oxidation;

[0032] (3) Put 20 g / L of the magnesium-aluminum layered composite into the adsorption reaction tank through the magnesium-aluminum layered composite oxide feeding part, use a stirring member to stir at 200 r / min for 4 hours to make the reaction fully, and let it stand for 1 hour to process ...

Embodiment 2

[0034] A method for treating hypophosphorous and phosphorous in waste water, comprising the following steps:

[0035] (1) Place the magnesium aluminum hydrotalcite in a crucible, calcinate it in a muffle furnace at 500°C for 4 hours, and after cooling, grind it through a 200-mesh sieve to obtain a magnesium aluminum layered composite oxide;

[0036] (2) in the oxidation reaction pool (in waste water, hypophosphorus concentration 7.5mg / L, phosphorous acid concentration 2.5mg / L, nickel ion concentration is about the waste water of 10mg / L) inject 40ml / L 30% hydrogen peroxide solution and Stir, and transfer the wastewater to the adsorption reaction pool after 10 minutes of sufficient pre-oxidation;

[0037] (3) Put 20 g / L of the magnesium-aluminum layered composite into the adsorption reaction tank through the magnesium-aluminum layered composite oxide feeding part, use a stirring member to stir at 200 r / min for 4 hours to make the reaction fully, and let it stand for 1 hour to pr...

Embodiment 3

[0039] A method for treating hypophosphorous and phosphorous in waste water, comprising the following steps:

[0040] (1) Place the magnesium aluminum hydrotalcite in a crucible, calcinate it in a muffle furnace at 500°C for 4 hours, and after cooling, grind it through a 200-mesh sieve to obtain a magnesium aluminum layered composite oxide;

[0041] (2) in the oxidation reaction pool (in waste water, hypophosphorus concentration 7.5mg / L, phosphorous acid concentration 2.5mg / L, nickel ion concentration is about the waste water of 10mg / L) inject 40ml / L 30% hydrogen peroxide solution and Stir, and transfer the wastewater to the adsorption reaction pool after 10 minutes of sufficient pre-oxidation;

[0042] (3) Put 40 g / L of the magnesium-aluminum layered composite into the adsorption reaction tank through the magnesium-aluminum layered composite oxide feeding part, use a stirring member to stir at 200 r / min for 4 hours to make the reaction fully, and let it stand for 1 hour to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com