Environment-friendly transparent PVC sheet

A transparent and environmentally friendly technology, used in applications, household appliances, flat products, etc., can solve the problems affecting the application of PVC sheets, the color of PVC sheets is yellow, and the crystal points are many, so as to improve transparency, improve regularity, The effect of increasing the refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

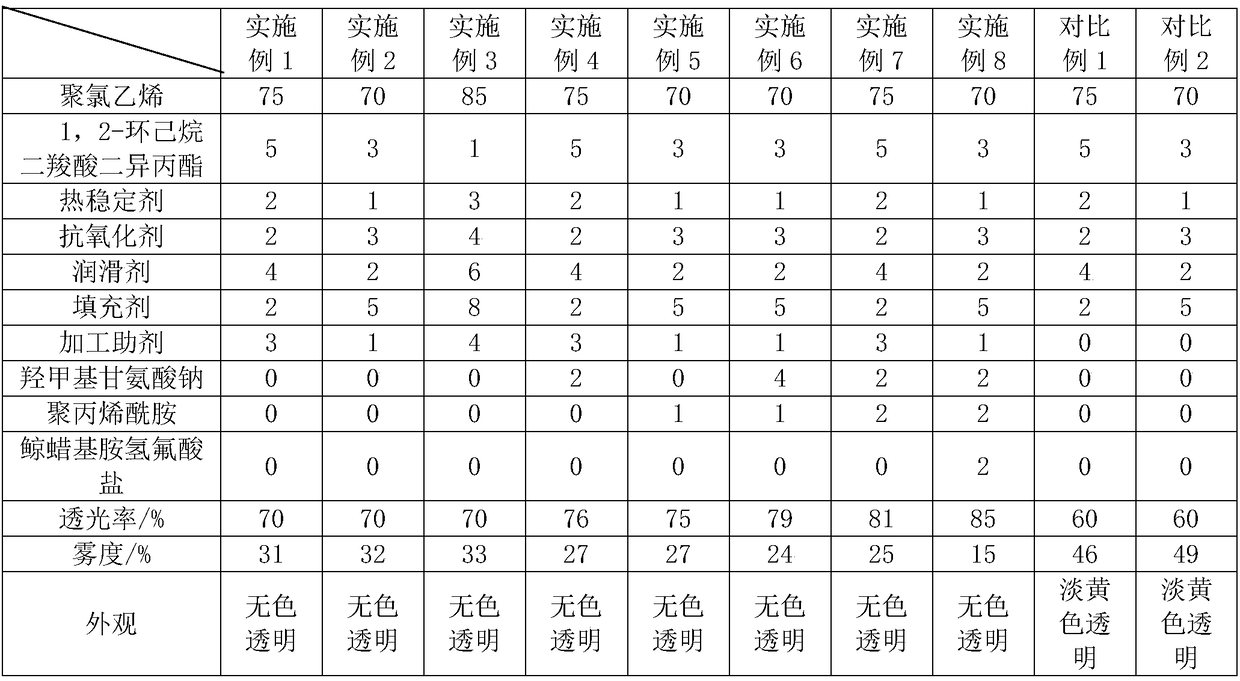

[0022] Embodiment 1: environmental protection colorless and transparent PVC sheet, the component and content of raw material are as shown in table 1, and the unit of each component in table 1 is kg, and processing aid is 6-methyl coumarin, antioxidant It is bisphenol A, the heat stabilizer is butyl tin, the filler is talcum powder, and the lubricant includes 2kg calcium stearate and 2kg paraffin.

[0023] The production process of the environmentally friendly colorless and transparent PVC sheet is as follows, step 1, batching, taking each component in the raw material, heating to 85°C, and stirring evenly. Step 2, extruding, cooling the material in step 1 to 50°C, feeding it into an extruder for extrusion, controlling the heating temperature of the extruder at 140-150°C, and controlling the plasticizing temperature of the material at 150-180°C. Step 3, calendering, the material extruded by the extruder is calendered with a calender, and the temperature of the calendering rolle...

Embodiment 2

[0024] Embodiment 2: Environmentally friendly, colorless and transparent PVC sheet. The difference from Embodiment 1 is that the components and contents of the raw materials are as shown in Table 1, and the lubricant includes 1kg calcium stearate and 1kg paraffin.

Embodiment 3

[0025] Embodiment 3: Environmentally friendly, colorless and transparent PVC sheet. The difference from Embodiment 1 is that the components and contents of the raw materials are as shown in Table 1, and the lubricant includes 3kg calcium stearate and 3kg paraffin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com