Light-emitting layer material for carbon-dot-based electroluminescent device

A technology of luminescent layer and carbon dots, which is applied in the direction of luminescent materials, electrical solid devices, electrical components, etc., can solve the problems of solid-state carbon dot fluorescence quenching, reduce the brightness of devices, etc. The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

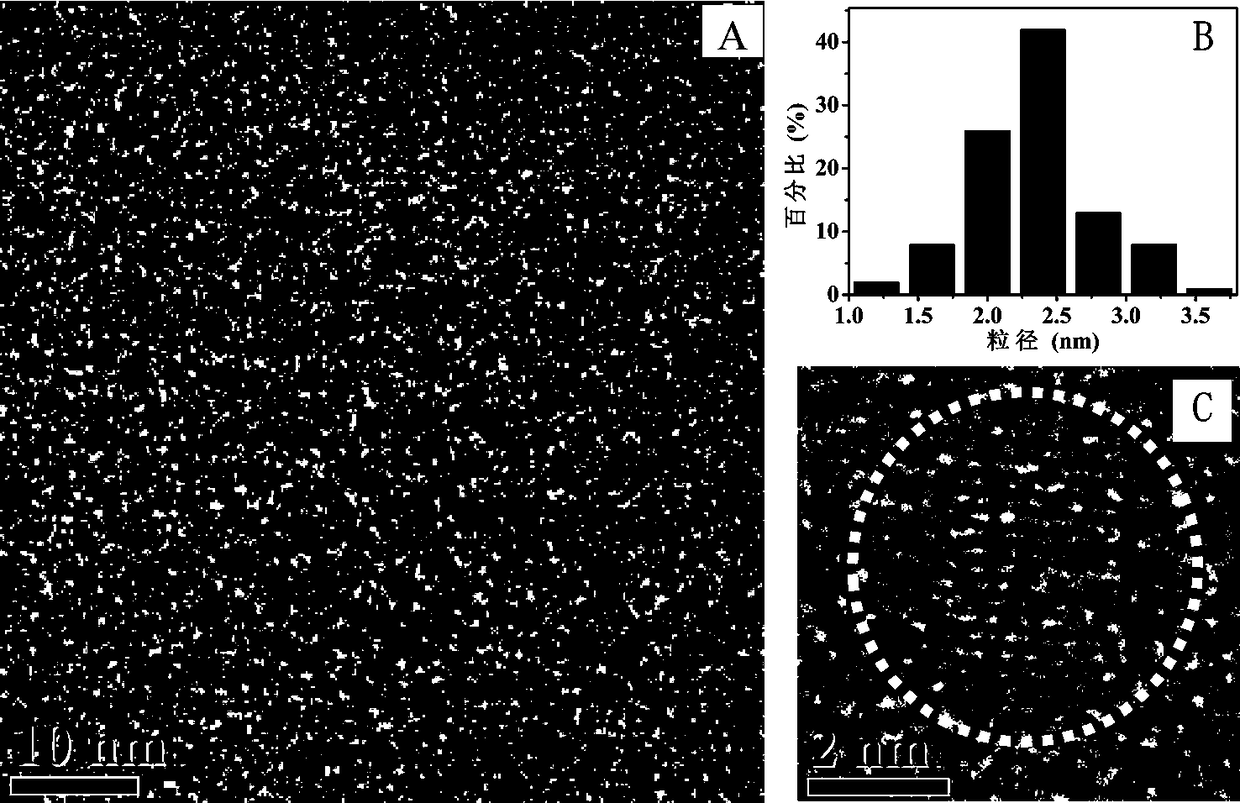

[0031] Add 0.3 g of anhydrous citric acid, 1.2 g of hexadecylamine, and 20 mL of octadecene into a 30 mL microwave reaction tube, and stir for 5 min to make them fully mixed.

[0032] The microwave reaction tube was placed in a microwave reactor, heated to 300° C. under microwave irradiation, and reacted for 10 minutes.

[0033] Heating was stopped after the reaction was completed, and the mixed solution was cooled to 55°C.

[0034] Take out the mixed solution, put it into a rotary evaporator, add 20mL of silica gel powder, connect the rotary evaporator to the rotary evaporator, seal it, set the temperature inside the rotary evaporator to 40°C, and evaporate the solvent to obtain a mixture of carbon dots and silica gel powder.

[0035] Measure 400mL of dichloromethane and 10mL of anhydrous methanol into a beaker to prepare an eluent.

[0036] Fill the chromatographic column with the mixture of carbon dots and silica gel powder prepared above, to the 2 / 3 of the chromatographic...

Embodiment 2

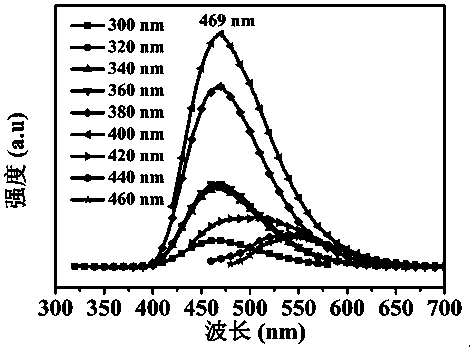

[0041] Weigh 4 mg of oil-soluble carbon dots and 4 mg of polyvinyl carbazole, and dissolve each in 1 mL of chlorobenzene to obtain a solution of oil-soluble carbon dots with a concentration of 4 mg / mL and a solution of polyvinyl carbazole of 4 mg / mL, respectively.

[0042] Measure 350mL of oil-soluble carbon dots solution, and fully mix with 650mL polyvinylcarbazole solution to obtain oil-soluble carbon dots / polyvinylcarbazole chlorobenzene mixed solution.

Embodiment 3

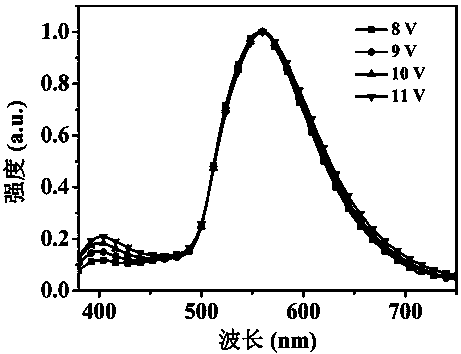

[0044] Weigh 10 mg of oil-soluble carbon dots and 10 mg of polyvinyl carbazole, and dissolve each in 1 mL of chlorobenzene to obtain a solution of oil-soluble carbon dots with a concentration of 10 mg / mL and a solution of polyvinyl carbazole of 10 mg / mL, respectively.

[0045] Measure 350mL of oil-soluble carbon dots solution, and fully mix with 650mL polyvinylcarbazole solution to obtain oil-soluble carbon dots / polyvinylcarbazole chlorobenzene mixed solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com