Preparing method and device for non-woven fabric with surface with protein film

A technology for preparing devices and proteins, which is applied to devices for coating liquid on surfaces, non-woven fabrics, textiles, and papermaking, etc., can solve problems such as protein inactivation, functional decline of mask nutrient solution, etc., and avoid the use of preservatives. , The effect of simplifying equipment composition and improving protein utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

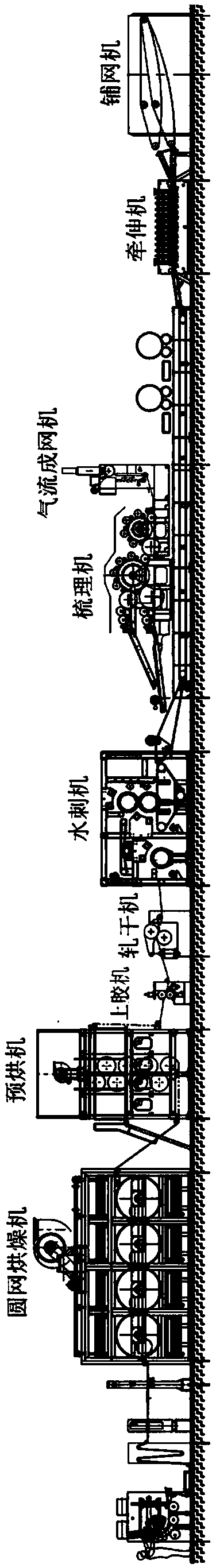

[0039] Disclosed in this embodiment is a method for preparing a non-woven fabric with a protein film on its surface, comprising the following steps:

[0040] S1: Woven non-woven fabric;

[0041] S2: In the process of weaving the non-woven fabric in S1, an attachment material containing protein is applied to at least one side of the fabric, so that a protein layer is attached to the surface of the fabric.

[0042] Wherein, the protein in the protein layer is one or more of silk fibroin, sericin, milk protein and various types of collagen, preferably silk fibroin.

[0043] In the present invention, silk fibroin protein is used, combined with the weaving link in the non-woven fabric, the protein is directly applied to the surface of the non-woven fabric in the preparation of the non-woven fabric, and the protein is attached to the surface of the non-woven fabric, and the process after the non-woven fabric The protein is dried together in the link, so that the protein is stored i...

Embodiment 2

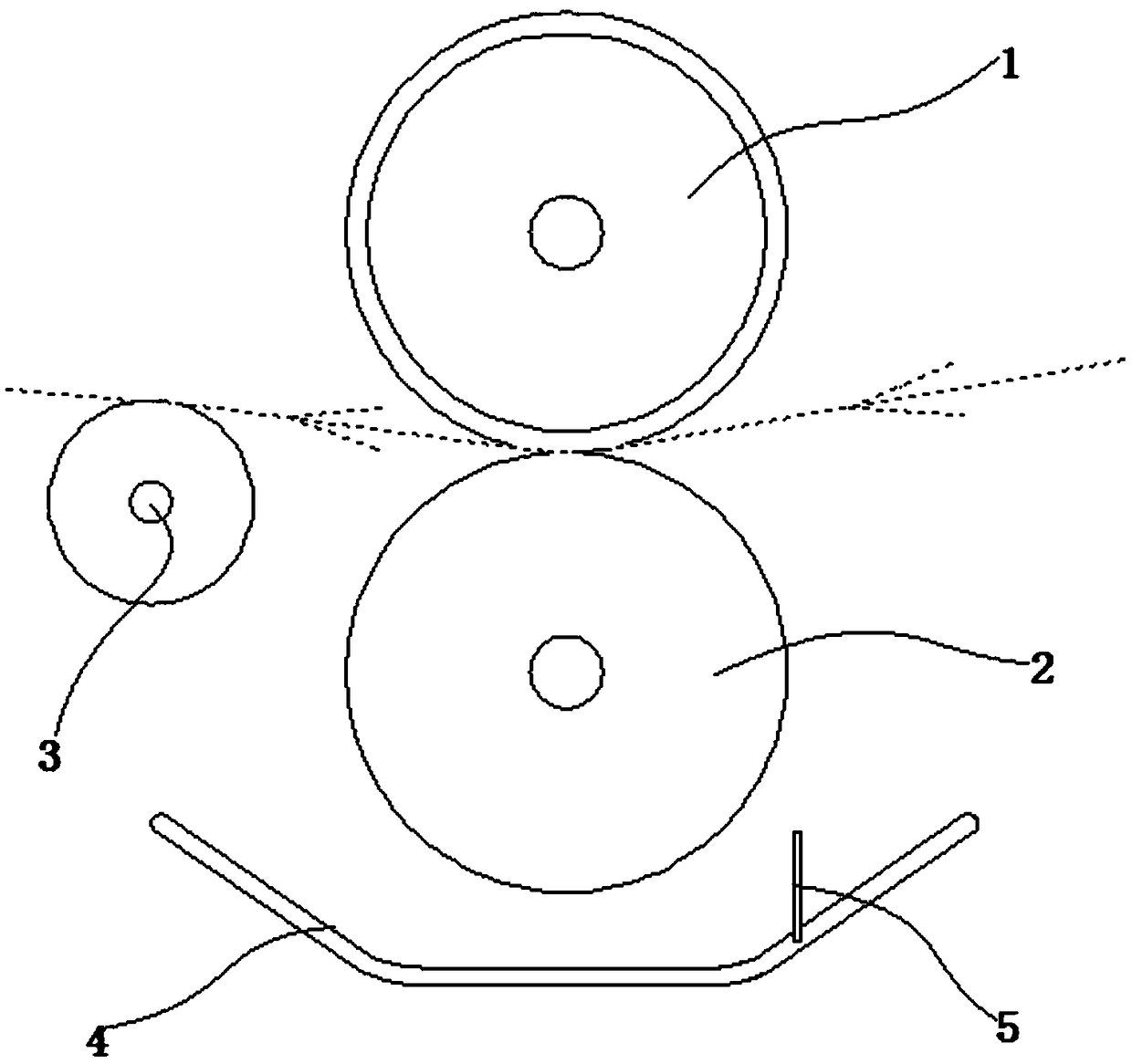

[0045] This embodiment discloses a method for preparing a non-woven fabric with a protein film on its surface: brush a glue layer on the surface of the non-woven fabric, then spray protein powder on the glue layer, and then form a protein layer on the surface of the fabric.

[0046]The present invention first coats the glue layer on the surface of the fabric, and then evenly sprays the protein powder on the surface of the glue layer, so that the protein powder can be deposited on the surface of the non-woven fabric in the form of a layered film by utilizing the adhesion and bonding of the colloid, which is beneficial Improve the protein utilization rate of non-woven fabrics in actual use.

Embodiment 3

[0048] This embodiment discloses a method for preparing a non-woven fabric with a protein film on its surface: the protein-containing attachment is applied to the surface of the fabric by roller printing to form a protein film structure. In the present invention, proteins (sericin, silk fibroin, milk protein, various types of collagen) are printed on non-woven fabrics in the form of attachments (viscous glue or printing liquid used in printing and printing, etc.) The protein is directly deposited on the surface, so that all the protein is concentrated on the surface of the non-woven fabric, and a protein film is formed on one side of the non-woven fabric, which is conducive to improving the protein utilization rate of the non-woven fabric in actual use.

[0049] In the present invention, the protein is attached to the surface of the fabric by printing and sizing, and the embossing effect in the printing method is fully utilized to improve the binding fastness between the protei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com