Graphene adhesion enhanced composite conductive structure and preparation method thereof

A composite conductive and composite structure technology, applied to conductive layers on insulating carriers, equipment for manufacturing conductive/semi-conductive layers, cable/conductor manufacturing, etc. problems such as large stress, to achieve the effect of large-area clean and non-destructive transfer, improved flatness, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

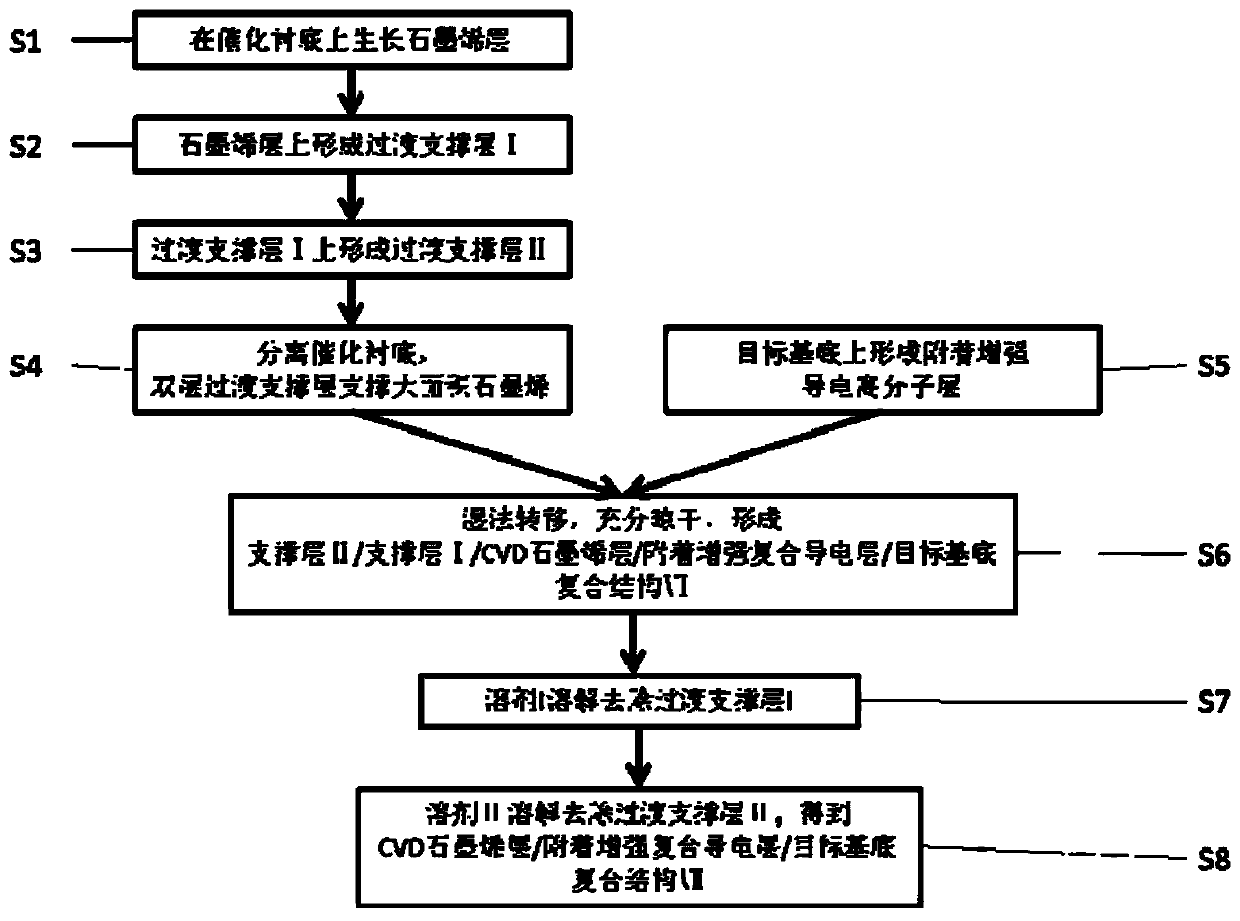

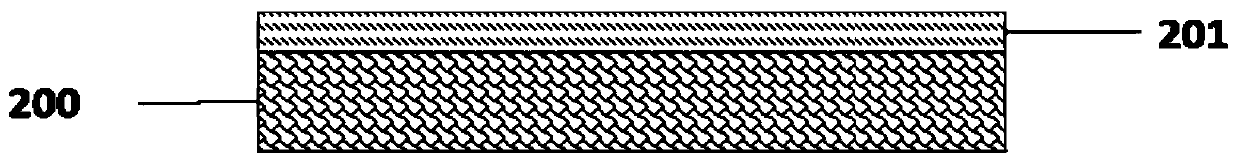

[0042] Such as figure 1 Shown, the present invention provides a kind of CVD graphene adhesion enhanced large-area transfer composite preparation method, comprising the following steps:

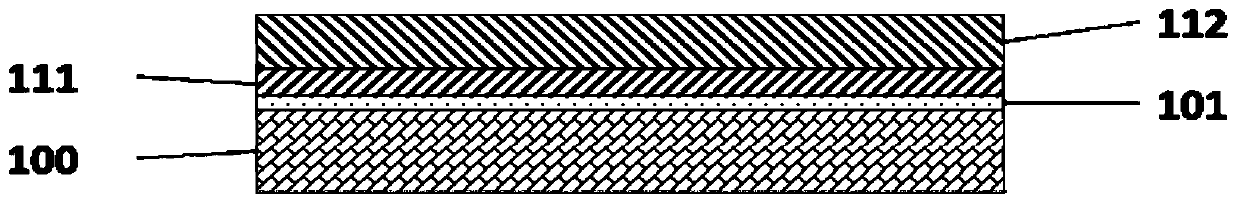

[0043] S1, growing a graphene layer 101 with a two-dimensional continuous structure on the catalytic substrate 100;

[0044] S2. Coating thermoplastic resin I on the surface of the graphene layer 101, and drying to form a film, to obtain a thin and rigid transition support layer I (111); the rigidity enables it to fully support the single-layer graphene structure, and is ultra-thin Make it fully adhere to the target substrate in the later stage.

[0045]In the traditional wet transfer process, a high-poly PMMA (polymethyl methacrylate) homopolymer resin is usually used as a transition support layer. This resin has defects in the transfer and release process: 1) high molecular weight and low solubility; 2 ) The monomer side group (methyl group) is small, and the commonly used synthesis proces...

Embodiment 1

[0080] In this embodiment, the graphene and the polymer conductive layer are transferred through a wet method to form a strong intermolecular coupling, and then the adhesion of the graphene to the PET substrate is enhanced, including the following steps:

[0081] Step S1, catalytically growing graphene with a two-dimensional continuous structure on the copper foil;

[0082] Step S2, coating the copolymer resin I-2 solution of special MMA and its derivatives on the graphene layer surface, concentration 5wt%; With BMA (butyl methacrylate): MMA (methyl methacrylate)=80 : 20 component distribution ratio, free radical solution random copolymerization, synthetic resin Ⅰ-2. Its physical and chemical parameters are as shown in Table 4, and the GPC (gel chromatography) spectrogram shows that its molecular weight is significantly smaller than the traditional high-poly PMMA resin under the premise of ensuring sufficient physical entanglement density, and its solubility is higher and easi...

Embodiment 2

[0097] The implementation steps S1-8 of this implementation are the same as the first embodiment, and the transparent composite conductive structure 1-2 is prepared.

[0098] Adhesion test: low-adhesive protective film, 8g / cm; slowly attach the protective film to the graphene surface from one side to avoid air bubbles or wrinkles when laminating, and press it tightly, let it stand for 1min, and reverse quickly at 180° Peel off the tape at an even speed. Test the conductivity, observe the morphology, and repeat the above operation steps several times, as shown in Table 6:

[0099] Table 6 Graphene 1-2 resistance to multiple sticking performance of protective film

[0100]

[0101] Continuation

[0102]

[0103] Continuation

[0104]

[0105] Continuation

[0106]

[0107] Continuation

[0108]

[0109] Continuation

[0110]

[0111] Continuation

[0112]

[0113] Continuation

[0114]

[0115] Continuation

[0116]

[0117] The test shows tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com