Reversible collagen stimulating filling agent and preparation method thereof

A filler and collagen technology, applied in the fields of soft tissue filling and medical beauty filling, to achieve good application prospects, environmental protection of technical routes, and the effect of stimulating collagen secretion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add hydroxybutyl chitosan with a concentration of 8.0 mg / mL and a hydroxybutyl substitution degree of 2.0 to the oil phase, the ratio of which to the oil phase is 7 wt%. Then 0.2wt% surfactant Tween 80 was added dropwise. Stir first at 5°C for 1 hour and then at 80°C for 1 hour. The oil phase was removed by suction filtration, and the collected microspheres were soaked in physiological saline at 80° C. for 24 hours. Screen particle size. Observe the shape of the pellets under a microscope.

[0027] Add the obtained hydroxybutyl chitosan microspheres into the hyaluronic acid gel at a ratio of 20%. Hyaluronic acid has a molecular weight of 10 6 Da, the concentration is 1.6wt%, the dynamic viscosity is 1.6*10 6 mPa s. It was then stirred at 500 rpm for 1 hour. Autoclave for 15 minutes and fill. The dynamic viscosity of the hybrid gel was tested by a rheometer.

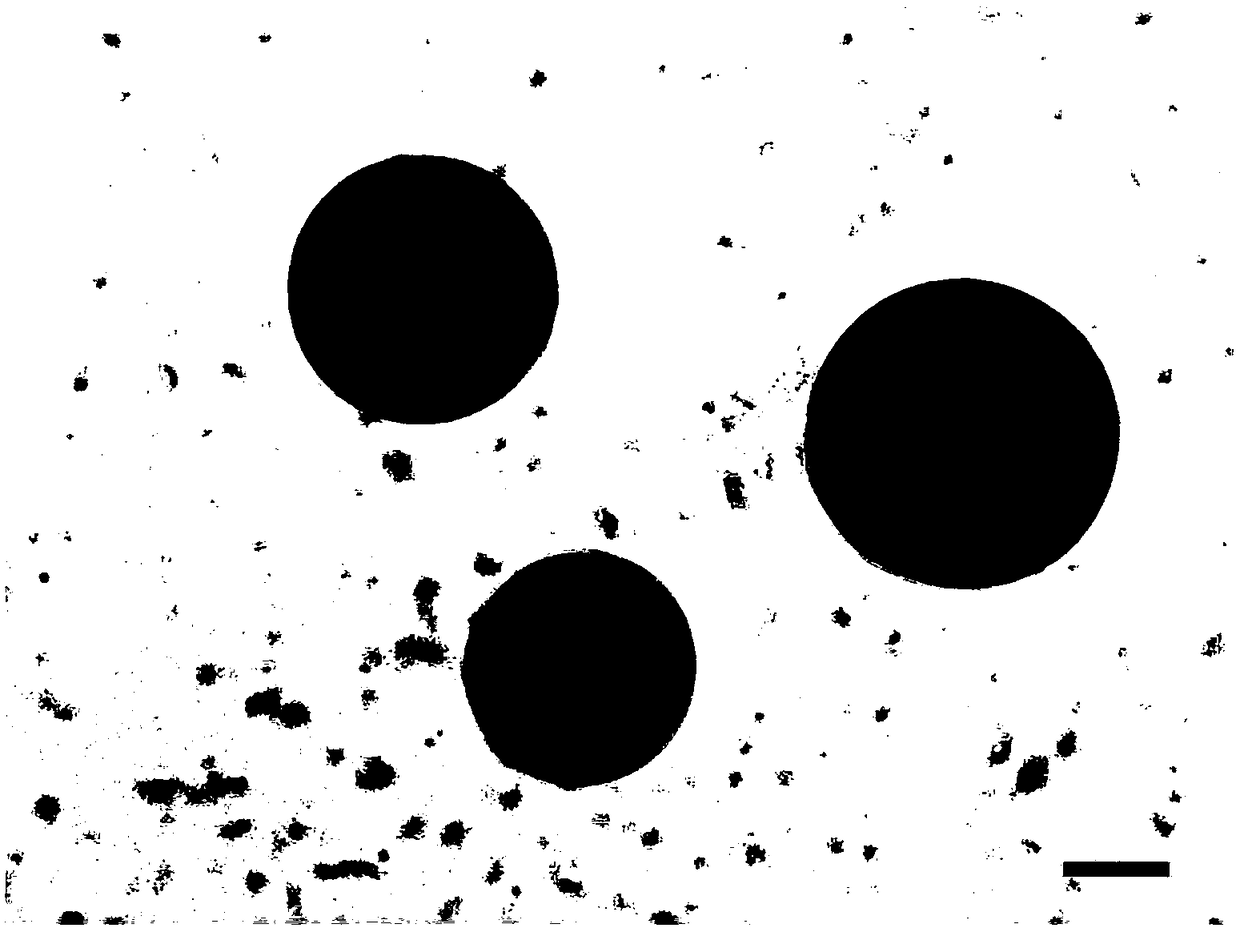

[0028] like figure 1 As shown, the prepared microspheres have a good spherical shape and a smooth surf...

Embodiment 2

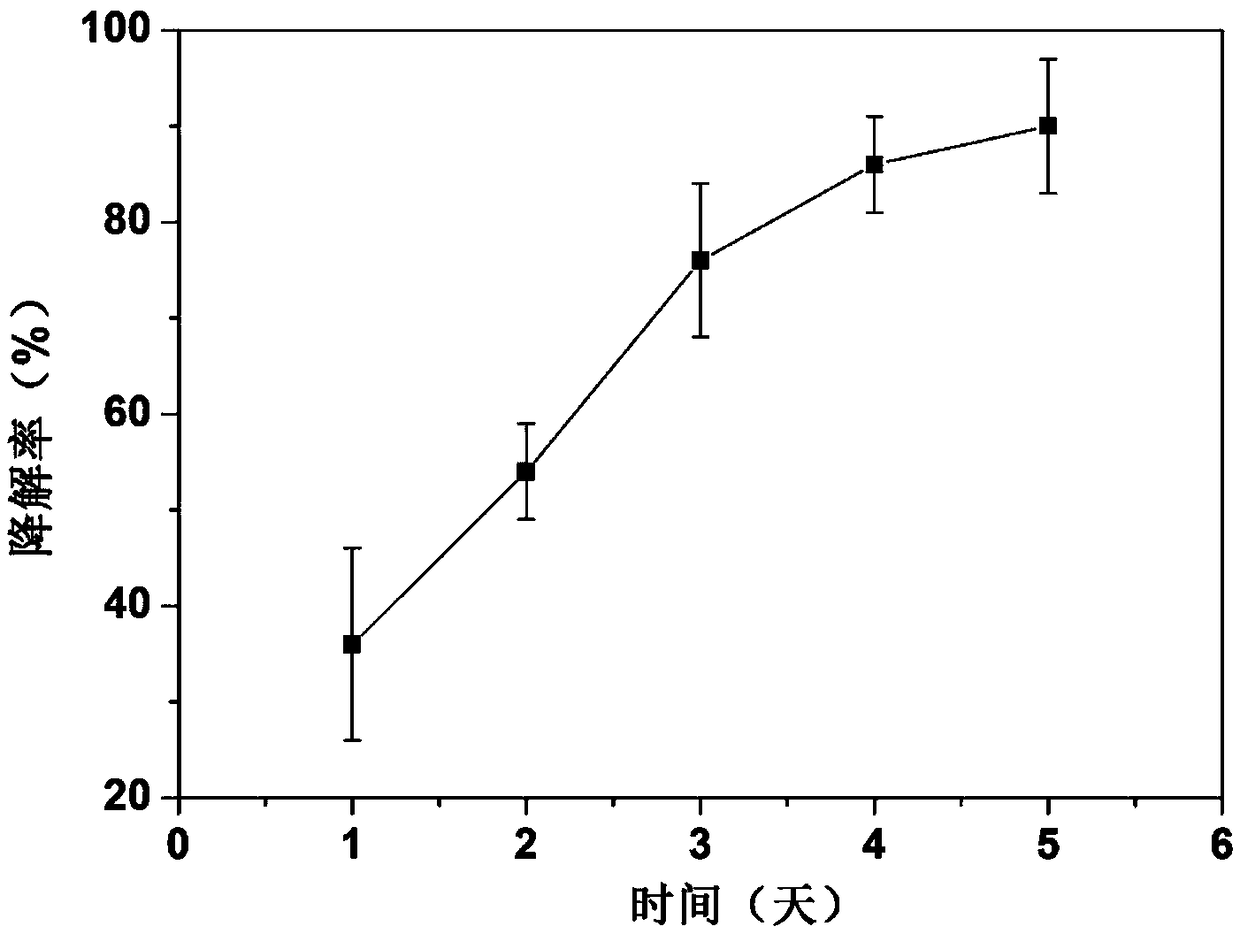

[0030]Take hydroxybutyl chitosan microspheres with a particle size of 20-30 μm, accurately weigh a certain mass and put it into a test tube. Prepare 2mg / mL lysozyme (20000U / mg) degradation solution. Add the degradation solution to the microspheres at a ratio of 10mg / g, replace it twice a day, take samples every day for 5 days, and weigh the mass after drying. The degradation rate was calculated according to the following formula:

[0031] Degradation rate (%) = (W 0 -W t ) / W 0 *100%

[0032] Among them, W 0 is the mass of microspheres before degradation, W t is the mass of remaining microspheres after degradation.

[0033] like image 3 As shown, under the conditions of accelerated degradation in vitro, the hydroxybutyl chitosan microspheres were degraded by 36% and 54% on the 1st and 2nd day, respectively, and about 90% by the 5th day. The above results show that hydroxybutyl chitosan microspheres can be rapidly degraded under the action of high concentration of lyso...

Embodiment 3

[0035] Add hydroxybutyl chitosan with a concentration of 10.0 mg / mL and a hydroxybutyl substitution degree of 1.7 to the oil phase, the ratio of which to the oil phase is 10 wt%. Then 0.2wt% surfactant Tween 80 was added dropwise. Stir first at 5°C for 1 hour and then at 80°C for 1 hour. The oil phase was removed by suction filtration, and the collected microspheres were soaked in physiological saline at 80° C. for 24 hours. Screen particle size. Observe the shape of the pellets under a microscope.

[0036] Add the obtained hydroxybutyl chitosan microspheres into the hyaluronic acid gel at a ratio of 10%. The molecular weight of hyaluronic acid is 1.3*10 5 Da, the concentration is 1.4wt%, the dynamic viscosity is 1.7*10 6 mPa s. Then it was stirred at 500 rpm for 1.5 hours. Autoclave for 15 minutes and fill.

[0037] The particle size of hydroxybutyl chitosan microspheres obtained in this example is 25-40 μm, and the degree of substitution of hydroxybutyl group decreas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com