Preparation and application of magnetic episulfide resin functional material

A technology of episulfide resin and functional materials, which is applied in other chemical processes, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of low adsorption capacity, and achieve increased specific surface area and increased specific surface area , The effect of increasing the active site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

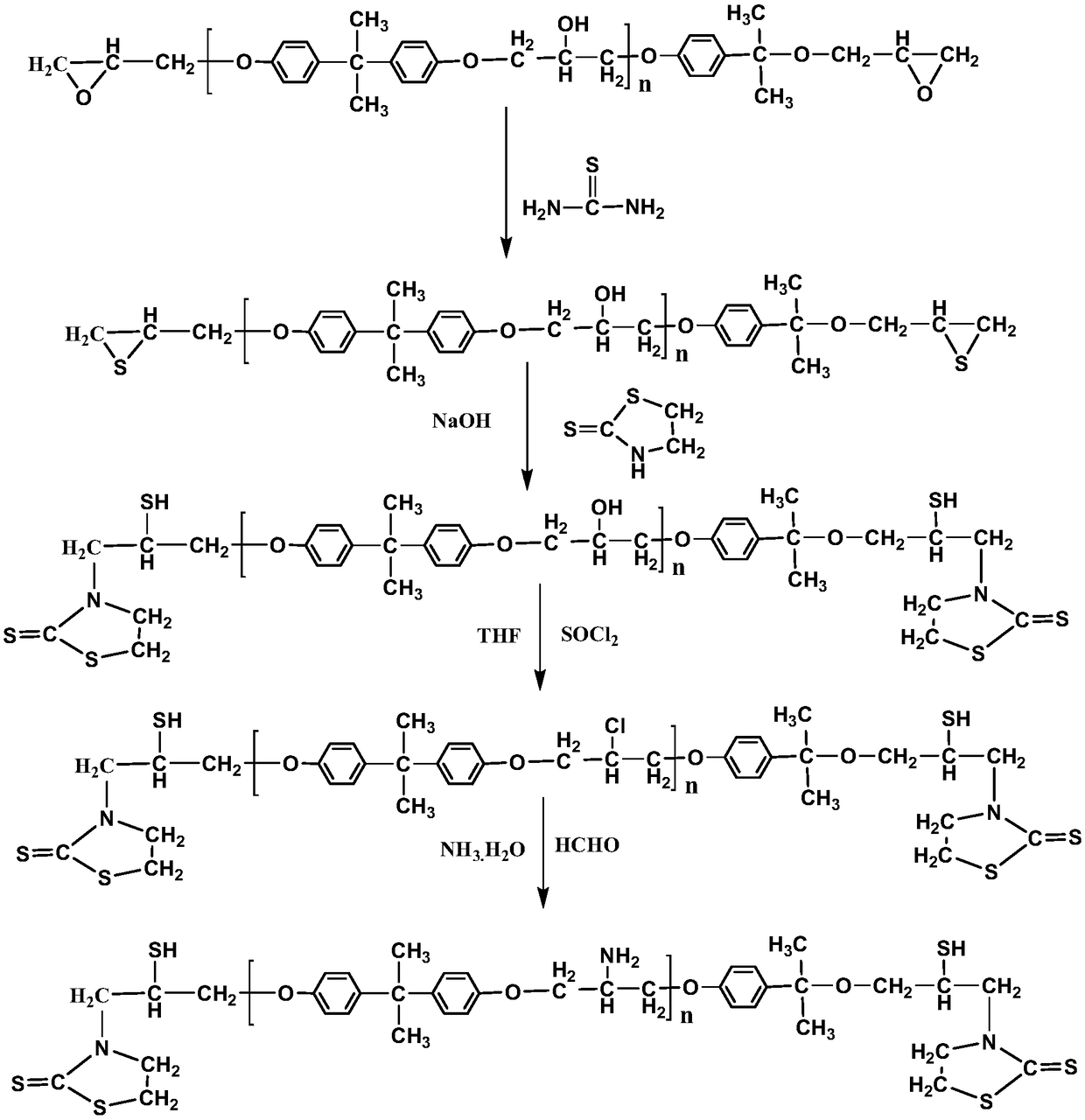

[0029] A kind of preparation of magnetic episulfide resin functional material comprises following preparation process:

[0030] The first step, the preparation of episulfide resin: add acetone solvent and 10g of bisphenol A epoxy resin to the reaction vessel, stir at room temperature until the bisphenol A epoxy resin is completely dissolved, and then reduce the temperature of the reaction vessel to -3°C - 0°C, then add 30.4g thiourea to it, stir until dissolved and then react at constant temperature for 80min, then raise the temperature to normal temperature and continue to react for 100min, then pour the mixture into a separatory funnel, collect the organic phase, and store the organic phase at 55°C Evaporate and remove the solvent therein to obtain episulfide resin;

[0031] The second step, ring-opening sulfuration reaction of episulfide resin: after dissolving 10g of episulfide resin prepared in the first step in acetone solution, add sodium hydroxide solution to adjust th...

Embodiment 2

[0035] A kind of preparation of magnetic episulfide resin functional material comprises following preparation process:

[0036]The first step, the preparation of episulfide resin: add acetone solvent and 10g of bisphenol A epoxy resin to the reaction vessel, stir at room temperature until the bisphenol A epoxy resin is completely dissolved, and then reduce the temperature of the reaction vessel to -3°C- 0°C, then add 30.4g thiourea to it, stir until dissolved and then react at constant temperature for 80min, then raise the temperature to normal temperature and continue to react for 120min, then pour the mixture into a separatory funnel, collect the organic phase, and store the organic phase at 55°C Evaporate and remove the solvent therein to obtain episulfide resin;

[0037] The second step, the ring-opening sulfuration reaction of the episulfide resin: after dissolving the 10g episulfide resin prepared in the first step in the acetone solution, add sodium hydroxide solution t...

Embodiment 3

[0040] A kind of preparation of magnetic episulfide resin functional material comprises following preparation process:

[0041] The first step, the preparation of episulfide resin: add acetone solvent and 10g of bisphenol A epoxy resin to the reaction vessel, stir at room temperature until the bisphenol A epoxy resin is completely dissolved, and then reduce the temperature of the reaction vessel to -3°C - 0°C, then add 30.4g thiourea to it, stir until dissolved and then react at constant temperature for 80min, then raise the temperature to normal temperature and continue to react for 100min, then pour the mixture into a separatory funnel, collect the organic phase, and store the organic phase at 55°C Evaporate and remove the solvent therein to obtain episulfide resin;

[0042] The second step, ring-opening sulfuration reaction of episulfide resin: after dissolving 10g of episulfide resin prepared in the first step in acetone solution, add sodium hydroxide solution to adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com