B/L acid-modified organosilicon sphere catalyst, and preparation and application thereof

A catalyst and organosilicon technology, applied in B/L acid-modified organosilicon ball catalyst and its preparation and application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

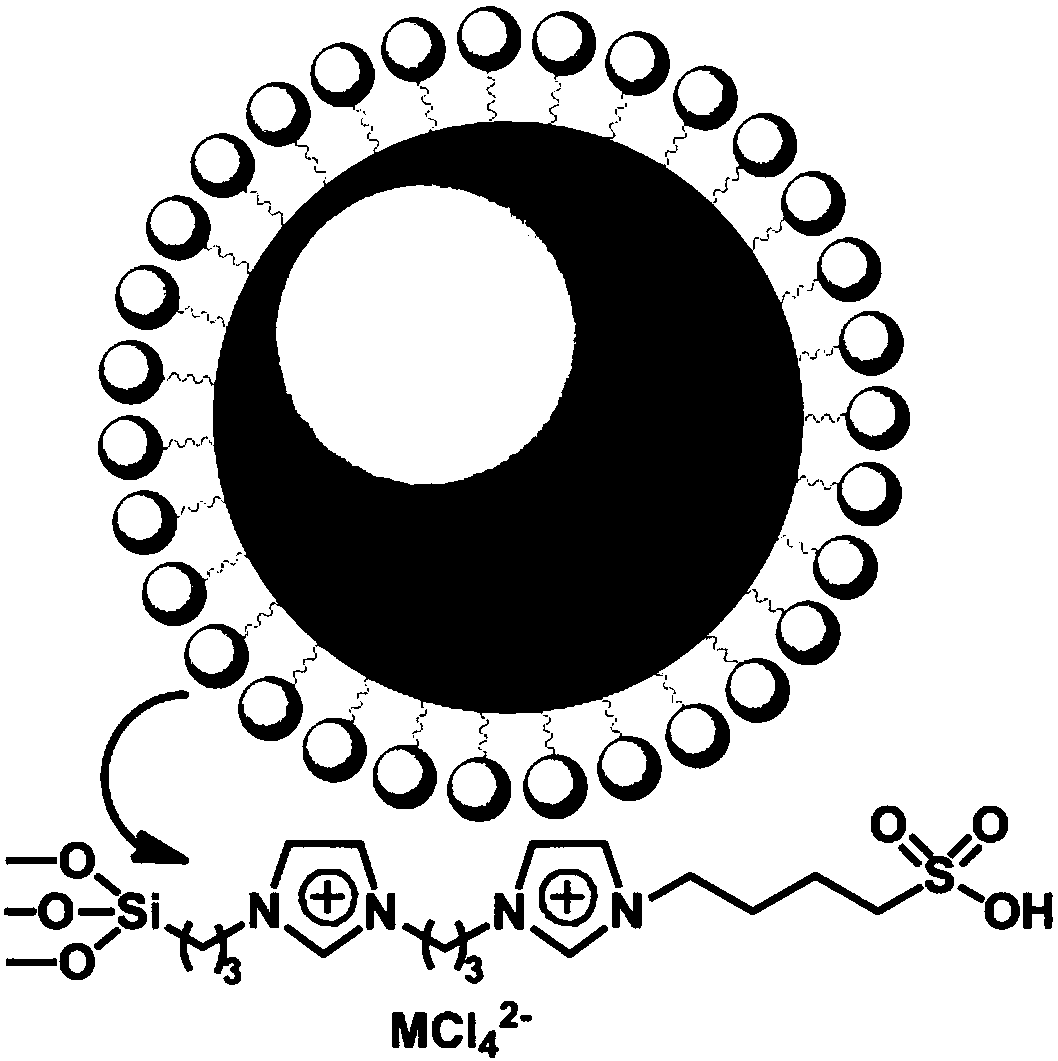

[0015] Catalyst M-S-BIM-SiO 2 preparation

[0016] The preparation of the organosilicon spheres modified by the B / L acid can be operated in the following steps:

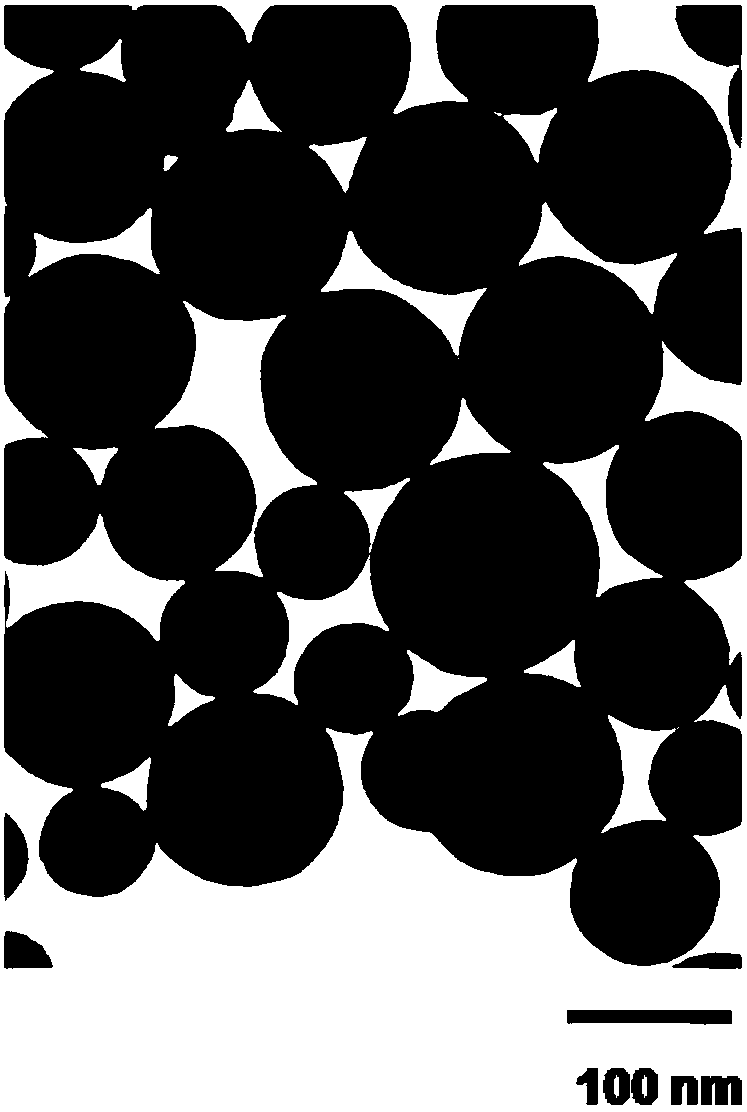

[0017] First, add 100mL of methanol, 10mL of ammonia water with a mass fraction of 28% and 30mL of deionized water into a 250mL three-necked flask, stir mechanically for 30 minutes, and then add 3.36g of ethyl orthosilicate and 0.19g of 3-chloro The precursor of propyltriethoxysilane was stirred at 60°C for 3 hours, centrifuged and washed with water to prepare organosilicon spheres for catalysts. Suspend 2 g of the prepared silicone spheres in 30 mL of toluene solution, drop an excess of 0.2 g of diimidazolidine, reflux at 120° C. for 12 hours, centrifuge and wash with water to prepare bis-imidazolidinyl-modified silicone spheres. Suspend 2 g of the prepared bis-imidazolidinyl-modified silicone spheres in 50 mL of toluene solution, add 0.35 g of excess 1,4-butane sultone dropwise into the suspension, stir the mixed...

Embodiment 2

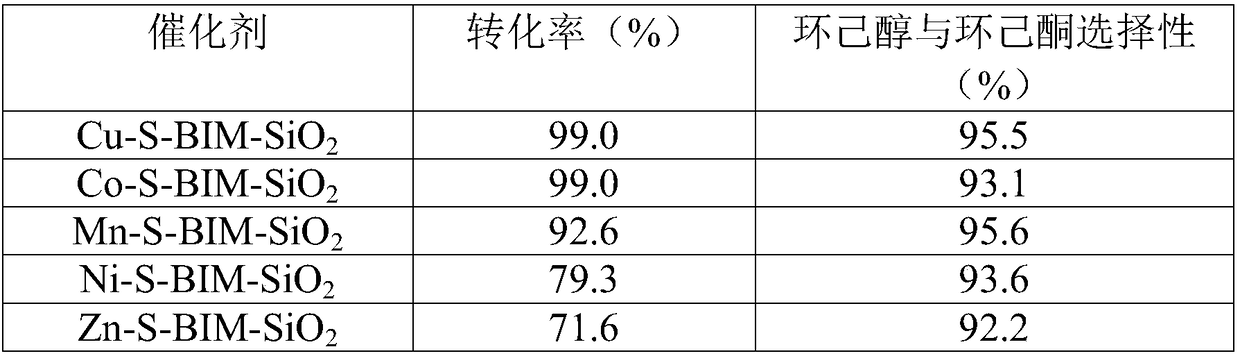

[0019] Catalyst Cu-S-BIM-SiO 2 preparation

[0020] Heterogeneous Catalyst Cu-S-BIM-SiO 2 The preparation method and M-S-BIM-SiO in Example 1 2 The preparation is the same, the difference is that the transition metal chloride salt used is CuCl 2 .

Embodiment 3

[0022] Catalyst Co-S-BIM-SiO 2 preparation

[0023] Heterogeneous Catalyst Co-S-BIM-SiO 2 The preparation method and M-S-BIM-SiO in Example 1 2 The preparation is the same, the difference is that the transition metal chloride salt used is CoCl 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com