60-degree crossed axis angle small-modulus straight bevel gear manufacturing method

The technology of a straight bevel gear and a manufacturing method is applied in the field of powder metallurgy products and can solve problems such as mold cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

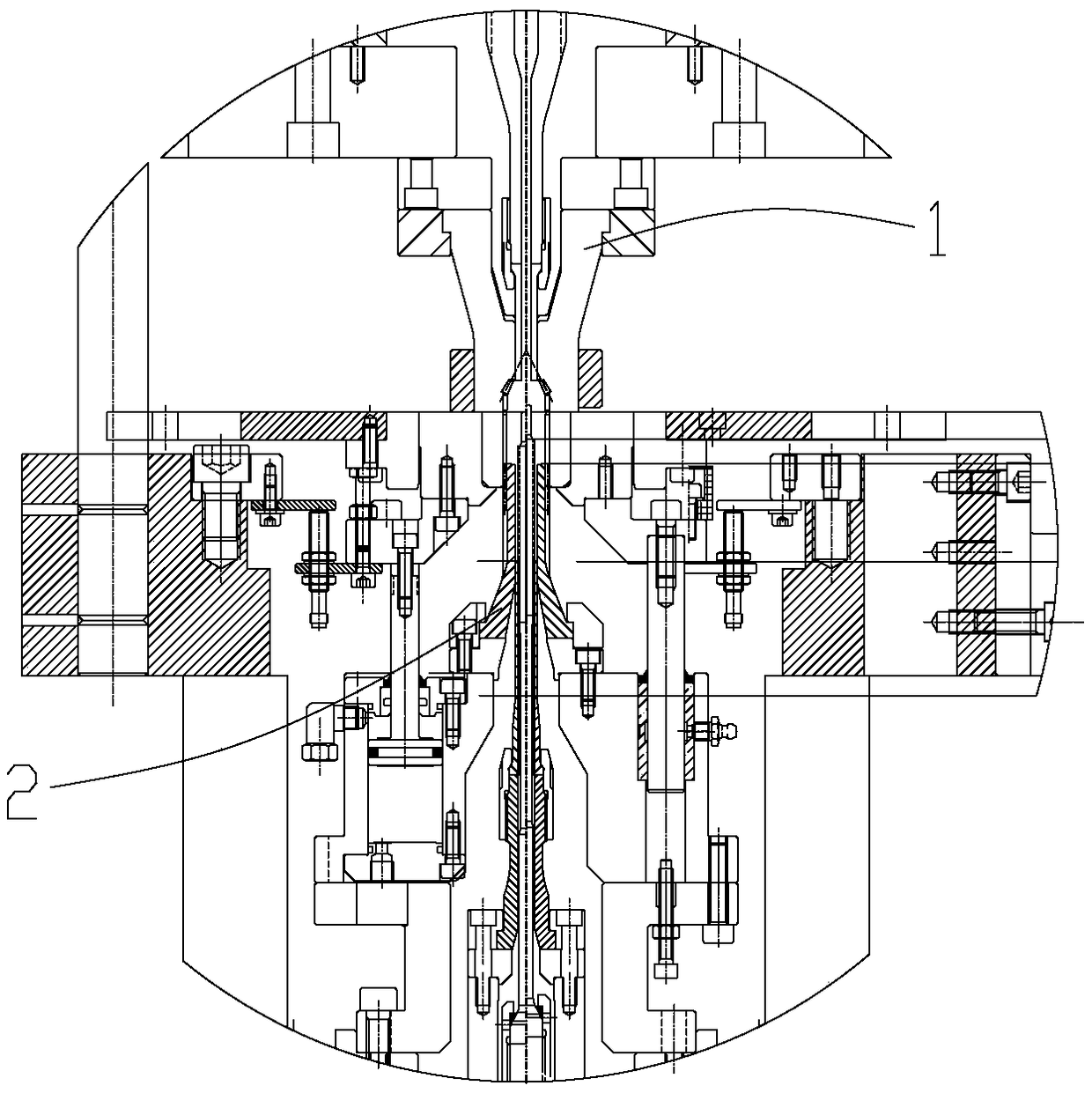

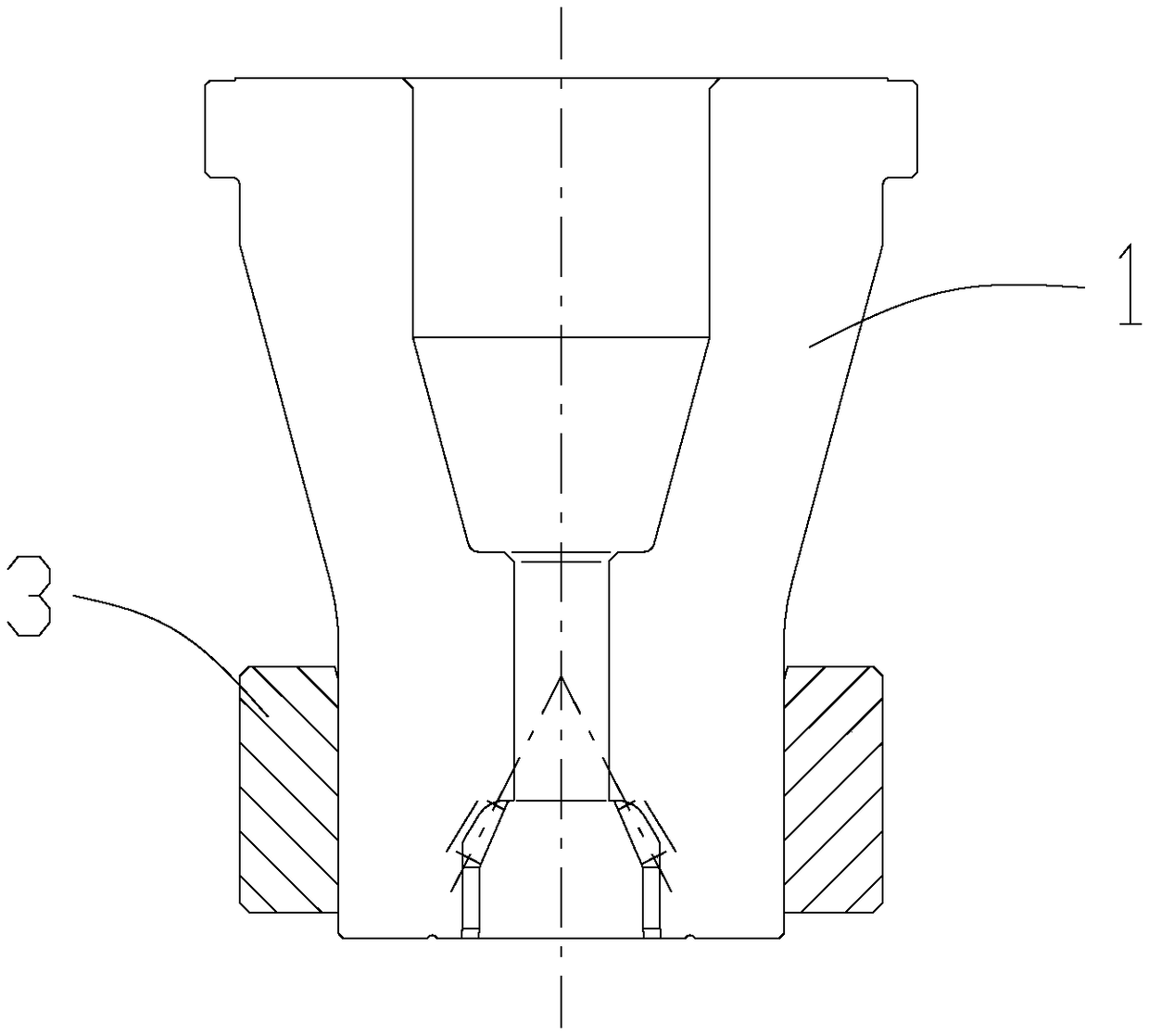

[0026] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0027] In this embodiment, a method for manufacturing a small-modulus straight bevel gear with a shaft angle of 60 degrees, the finished product specifications of the small-modulus straight bevel gear studied are: the shaft angle is 60 degrees, the transmission ratio is 15:18, and the indexing cone angle is 27 degree ±3° degree; the density requirement is ≥7.05g / cm3, the hardness is ≥67 HRA, the thickness of the infiltrated layer is between 0.2-1 mm, and the torque is ≥28.5 Nm.

[0028] The make method has the following:

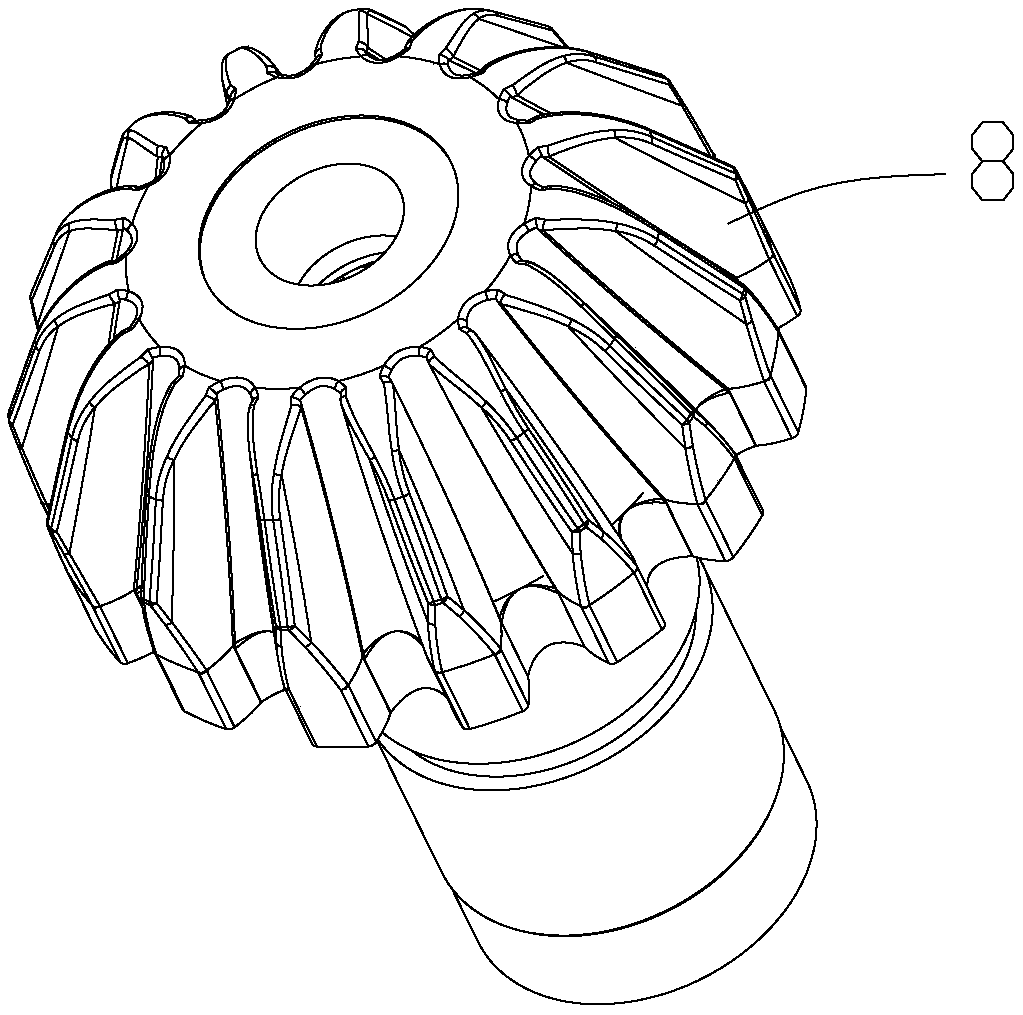

[0029] 1. Electrode design, according to figure 1 Product-related parameters, build a 3D model, and simulate in the software. By changing the technical parameters, the satisfactory contact area of the bevel gear in the working state is calculated through computer simulation. For ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com