Method for high-speed optical fiber laser welding for pure titanium plate with thickness of 1mm

A fiber laser, pure titanium technology, used in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of lower yield, low welding speed, easy oxidation of welds, etc., to improve the upper limit of processing capacity , to ensure the quality of the weld and avoid the effect of weld spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

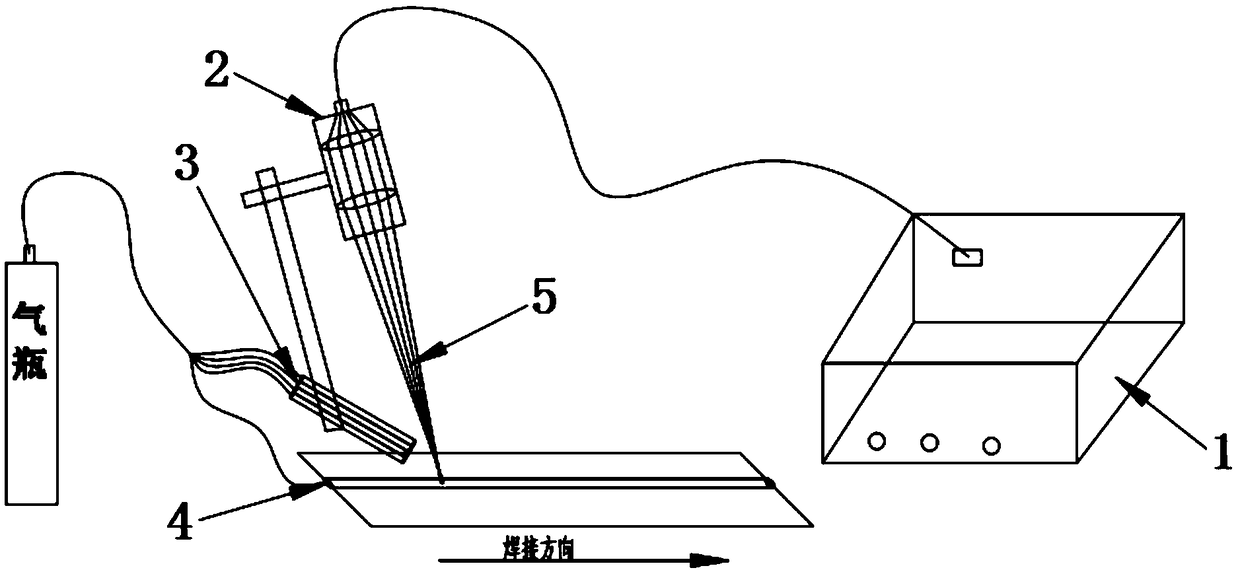

[0012] The present invention will be further described in conjunction with the accompanying drawings.

[0013] Such as figure 1 Shown, the method for a kind of 1mm pure titanium plate high-speed optical fiber laser welding of the present invention is carried out according to the following steps: (1), the laser beam 5 of laser 1 is focused on the 1mm pure titanium plate surface through the optical system in welding head 2, 1mm The welding seam formed by melting the pure titanium plate after absorbing the laser; (2), the welding head is connected to the protective gas tube 3 in the row and the argon protection provided by the back shielding gas chamber 4, and the welding seam is formed after melting; (3), the moving welding head is welded 1mm Pure titanium plate; it is characterized in that: (4), the transmission fiber diameter of laser 1 output laser beam 5 is 100um, and welding head 2 is 60°-75° with horizontal direction, and the laser beam 5 focal spot that welding head 2 out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com