Semi-solid state acid-sensitive amphiphilic block copolymer, and preparation method and application thereof

An amphiphilic block and copolymer technology, which can be used in pharmaceutical formulations, drug combinations, drug delivery, etc., can solve the problems of hydrophobic drug loading and encapsulation rate limitations, cumbersome reaction steps, and a large amount of organic solvents. Achieve the effect of enhancing body circulation time, simple and easy to obtain synthetic raw materials, easy loading and solubilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

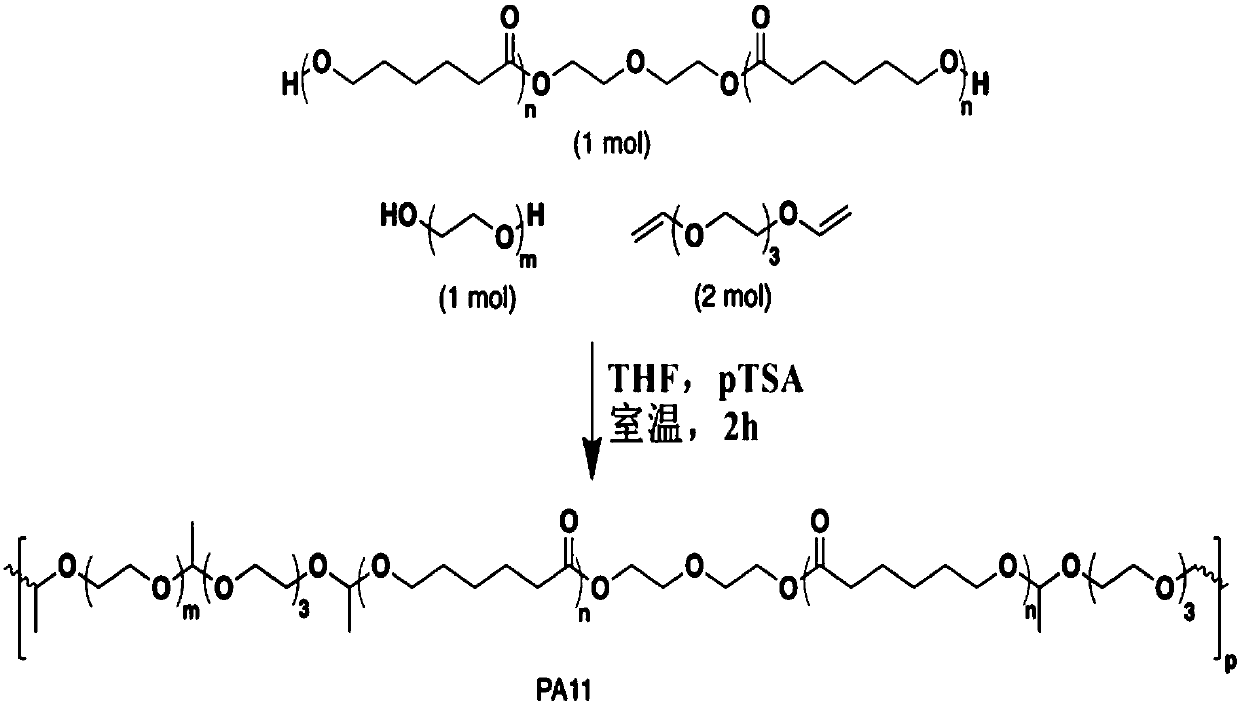

[0051] A kind of acid-sensitive amphiphilic block copolymer is made by following method:

[0052] (1) Put polyethylene glycol and polycaprolactone diol in a vacuum drying oven for 16 hours to dry, and set aside. THF was dried over sodium metal.

[0053] (2) Weigh a certain amount of polyethylene glycol (molecular weight about 400) and polycaprolactone diol (molecular weight about 530), with a mass ratio of 1:1, and add it to the silanized Dry the flask, and then add tetrahydrofuran to completely dissolve the reactant under stirring, and the added volume (ml) of the tetrahydrofuran is about 2 times the mass (mg) of the reactant. Then add tri(ethylene glycol) divinyl ether or 1,4-butanediol divinyl ether, and the divinyl ether compound is mixed with polyethylene glycol and polycaprolactone diol in the reaction system. The mass ratio of the total amount is 1:1. After stirring for 5 minutes to uniformly mix all the reactants, 5% p-toluenesulfonic acid was added as a catalyst fo...

Embodiment 2

[0056] The semisolid properties of acid-sensitive amphiphilic polymers were studied using the following methods:

[0057] Steps (1), (2), (3) are the same as in Example 1;

[0058] (4) Mix the above-mentioned copolymers with water at a ratio of 1:0, 2:1, 1:1, 1:2, 1:4, and use a rheometer (AR-G2) to detect the polymer itself and The change of viscosity with temperature after interacting with water reflects the semi-solid nature of the polymer itself. The fluidity of the acid-sensitive polymer itself is as Figure 4 shown. Rheological test results such as Figure 5 shown. The viscosity of amphiphilic polymers is closely related to changes in temperature. As the temperature increases, the viscosity of the polymer decreases accordingly. When the temperature rises to 50°C, its viscosity is as small as 20-30% of the initial viscosity at 20°C. When the temperature increased to 37°C, the viscosity of all the samples decreased significantly, and all of them showed a semi-solid s...

Embodiment 3

[0060] A preparation method of a circulatory drug delivery preparation of acid-sensitive polymer solubilized hydrophobic probe Nile Red, which is prepared by the following method:

[0061] Steps (1), (2), (3) are the same as in Example 1;

[0062] (4) Add 3 mg of Nile Red to 100 mg of the above-prepared copolymer material, mix well, and leave overnight (14 hours). The prepared Nile Red-loaded polymer was mixed with water at a mass ratio of 1:50, oscillated evenly, filtered through a 0.45 μm filter membrane, and the filtrate was collected to prepare an acid-sensitive polymer solubilizing hydrophobic probe Nile Red. Cycle dosing formulations. Figure 6 It is the encapsulation and solubilization behavior of PCL-PA-PEG copolymer to the hydrophobic model drug Nile red. It can be seen that the hydrophobic probe Nile Red is dispersed in water, and the suspension rapidly separates and settles, while the acid-sensitive polymer loaded with Nile Red can be well dispersed in water, form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com