A method for determining vitamin a, d, e in milk powder

A vitamin and milk powder technology, applied in the field of analytical chemistry, can solve problems such as inability to meet the test requirements of low-content samples, matrix interference, chromatographic column damage, etc., achieve automatic online purification detection, ensure accuracy and reproducibility, save manpower and The effect of reagent cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

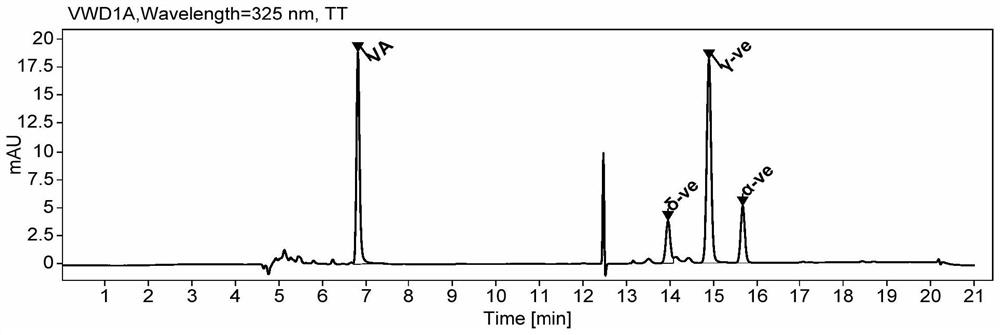

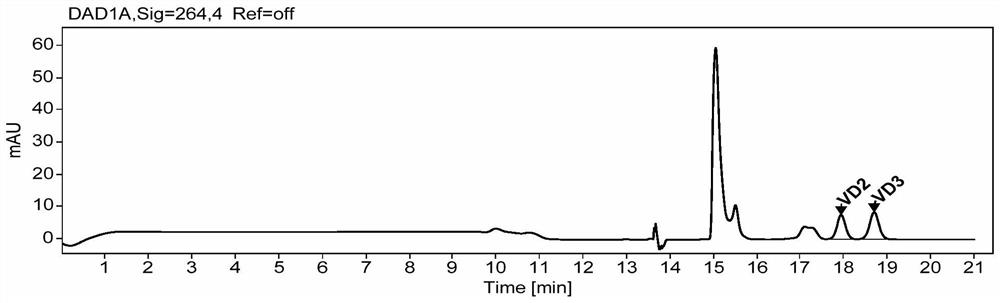

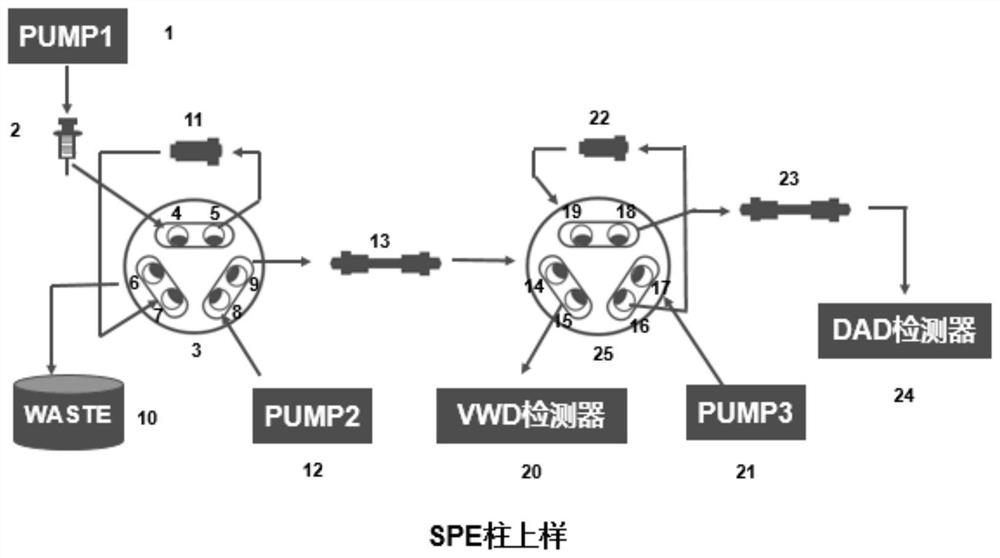

[0042] Embodiment 1: the mensuration of vitamin A in milk powder, D, E

[0043] 1. Sample preparation:

[0044] Accurately weigh 2g of the mixed sample into a 150mL flat-bottomed flask, add 20mL of distilled water, 30mL of absolute ethanol, 1g of ascorbic acid, 1g of BHT, 20mL of 50% KOH aqueous solution, heat in a water bath at 80°C for 30min, cool to room temperature after completion, and use 50% Dilute ethanol water solution to 100mL, take 2mL through a 0.45μm filter membrane, and analyze on the machine.

[0045] 2. Set the instrument parameters:

[0046] The operating conditions of the online solid phase extraction part are:

[0047] (1) The vitamin A, D, E enrichment purification column adopts PLRP-S column, the specification is 4.6×12.5mm, and the pore size is 15-20um;

[0048] (2) The mobile phase is 40% ethanol aqueous solution, and the running time is 22min; the mobile phase flow rate: 0-4min is 1mL / min; 4-15min is 0.2mL / min; 15-22min is 1mL / min, and the injection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com