Negative electrode material for potassium-ion battery, preparation method thereof and negative electrode sheet

A technology of negative electrode material and negative electrode sheet, which is applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of short cycle life, low specific capacity, poor rate performance, etc., achieve long cycle life, increase specific capacity, improve Effect of Magnification Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] According to a second aspect of the present invention, a kind of preparation method of negative electrode material for potassium ion battery is provided, comprising the following steps:

[0041] (1) Disperse chitin powder in a mixed solution of NaOH, urea and water, wherein NaOH accounts for 6wt%-14wt% of the mixed solution, urea accounts for 2wt%-6wt% of the mixed solution, and the freezing temperature is -20°C to - Keep at 45°C for 2 hours to 6 hours, and perform several freeze-thaw cycles until a transparent first solution is obtained;

[0042] (2) Add the first solution to the mixed solution of isooctane and Span 85, wherein the mass ratio of the first solution, isooctane and Span 85 is 16:40:1, stir at -10°C-0°C 0.5 hour-2 hours, obtain the second solution;

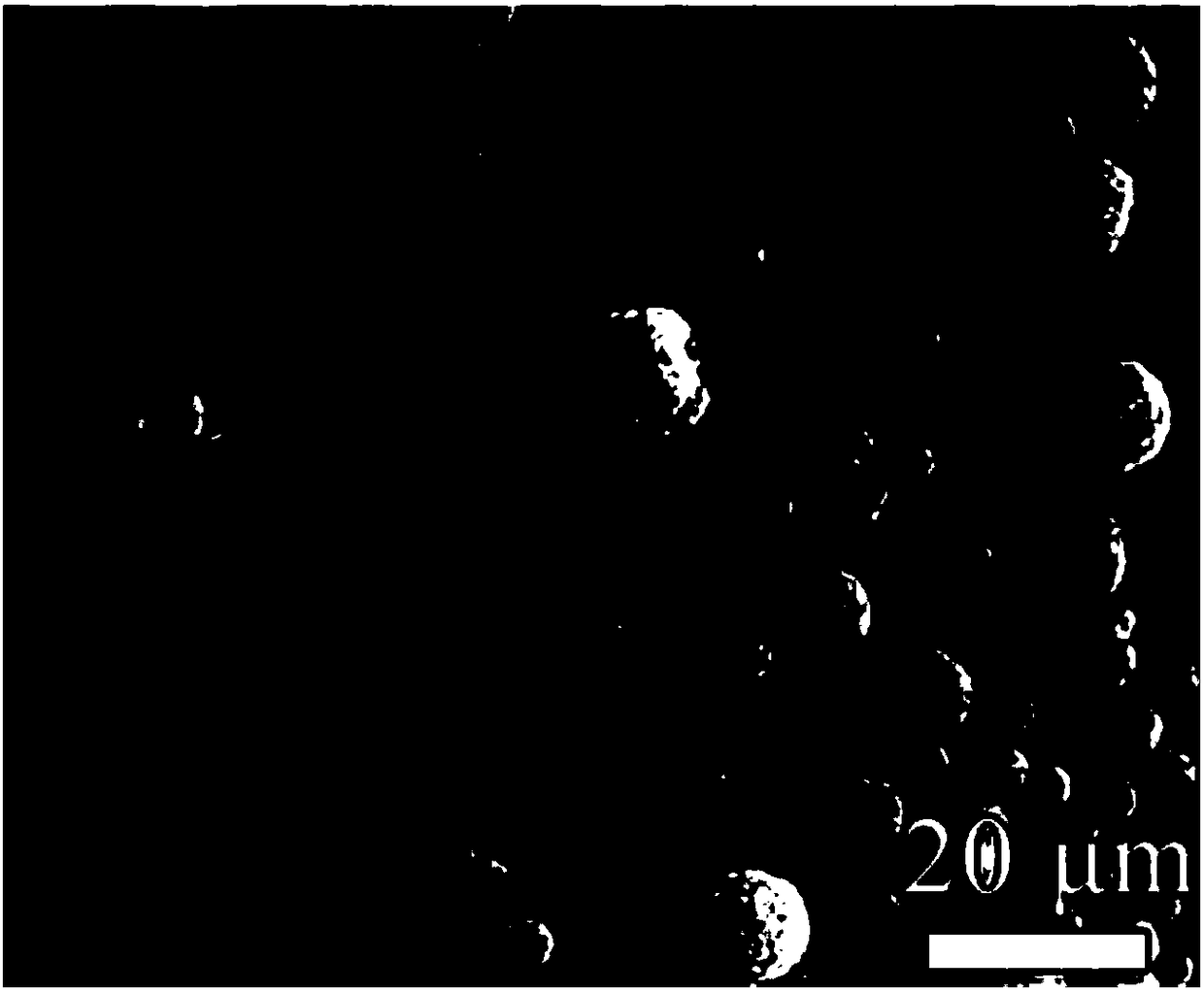

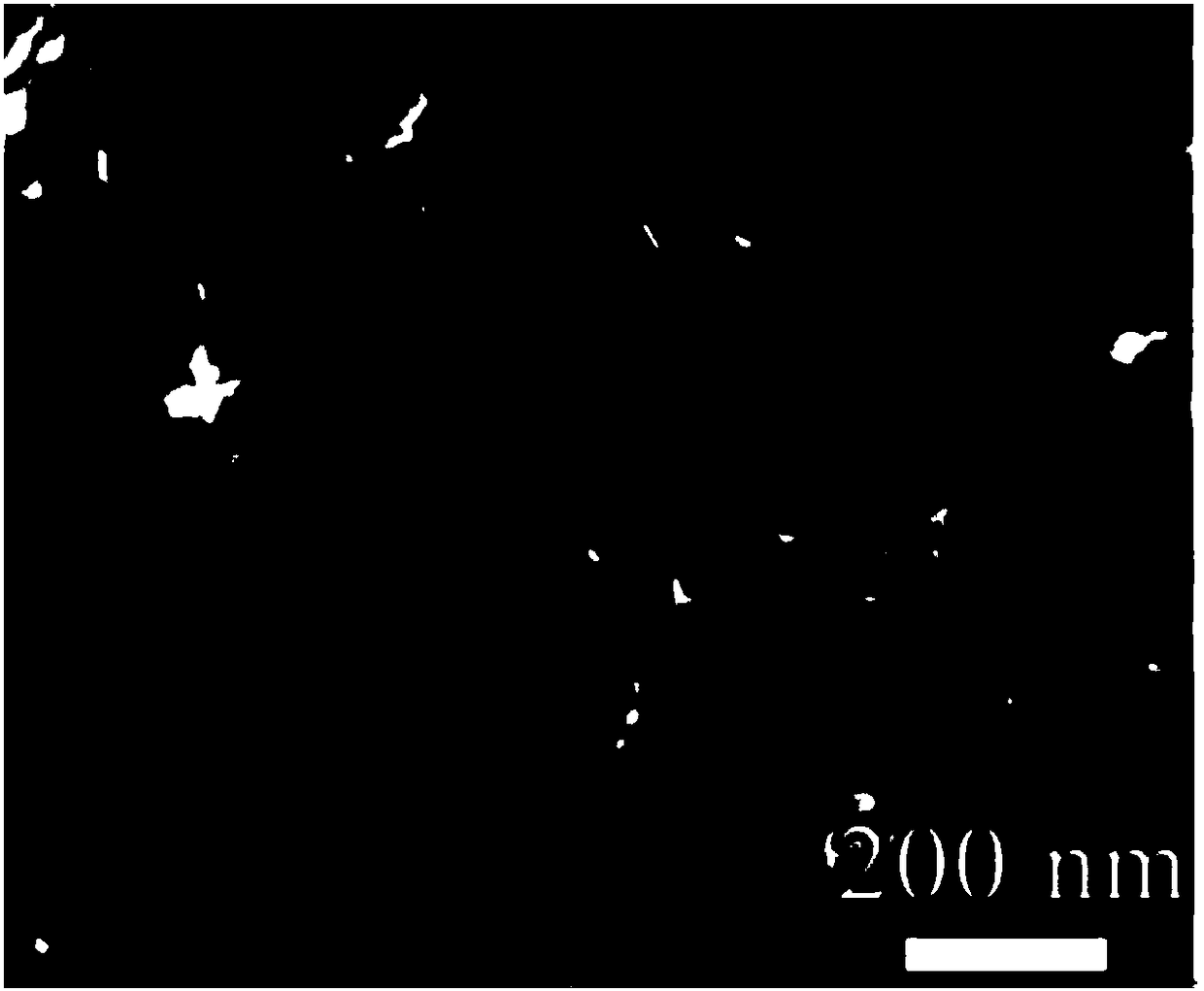

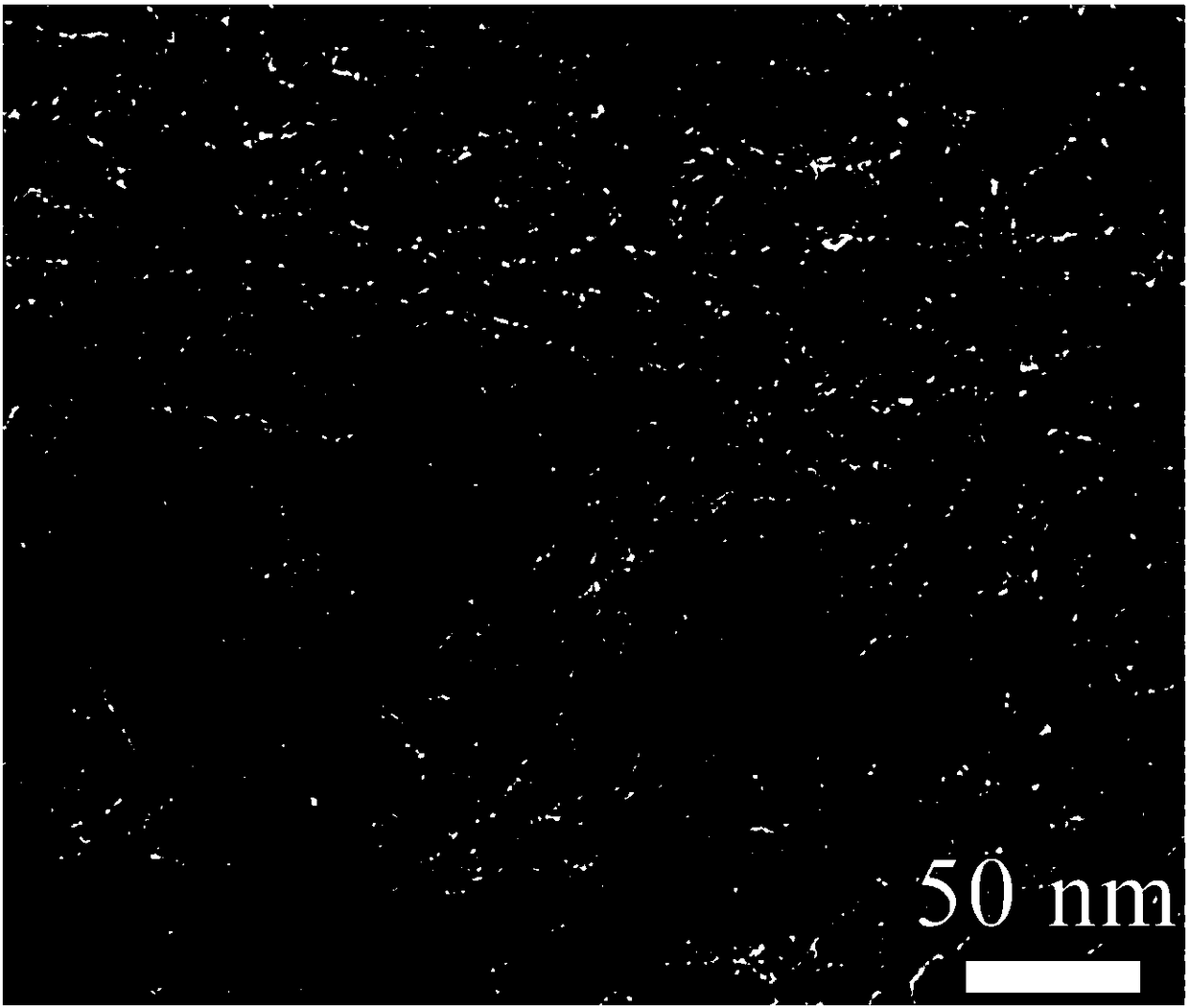

[0043] (3) Centrifuge the second solution to obtain the carbon microsphere precursor, wash the carbon microsphere precursor several times with ethanol and water to obtain the third solution, and freeze the th...

Embodiment 1

[0054] A preparation method for a negative electrode material for a potassium ion battery, comprising the following steps:

[0055] (1) Disperse the chitin powder in a mixed solution of NaOH, urea and water, wherein NaOH accounts for 10wt% of the mixed solution, urea accounts for 4wt% of the mixed solution, the freezing temperature is -30°C, keep for 4 hours, and freeze- Thaw several cycles until a clear first solution is obtained;

[0056] (2) Add the first solution to the mixed solution of excess isooctane and a small amount of Span 85 and mix well, wherein the mass ratio of the first solution, isooctane and Span 85 is 16:40:1. Stir for 0.5 hour to obtain the second solution;

[0057] (3) Centrifuge the second solution to obtain the carbon microsphere precursor, wash the carbon microsphere precursor several times with ethanol and water to obtain the third solution, freeze-dry the third solution at -30°C for 4 hours to obtain Nitrogen-doped porous carbon nanofibers;

[005...

Embodiment 2

[0079] A preparation method for a negative electrode material for a potassium ion battery, comprising the following steps:

[0080] (1) Disperse the chitin powder in the mixed solution of NaOH, urea and water, wherein NaOH accounts for 6wt% of the mixed solution, urea accounts for 6wt% of the mixed solution, the freezing temperature is -20°C, keep for 6 hours, and freeze- Thaw several cycles until a clear first solution is obtained;

[0081] (2) Add the first solution to the mixed solution of excess isooctane and a small amount of Span 85, mix well, and stir at -5°C for 1 hour to obtain the second solution;

[0082] (3) Centrifuge the second solution to obtain the carbon microsphere precursor, wash the carbon microsphere precursor several times with ethanol and water to obtain the third solution, freeze-dry the third solution at -20°C for 6 hours to obtain Nitrogen-doped porous carbon nanofibers;

[0083](4) The nitrogen-doped porous carbon nanofibers were heat-treated for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com