Preparation method and application of supported copper-based catalyst with enhanced surface acidity

A copper-based catalyst, supported technology, which is used in catalyst activation/preparation, heterocyclic compound preparation, chemical instruments and methods, etc., can solve the problem of low recycling rate, difficult to control surface acid sites, and small interaction between metal Cu and supports and other problems, to achieve the effect of improving catalytic performance and stability, improving strong interaction, and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

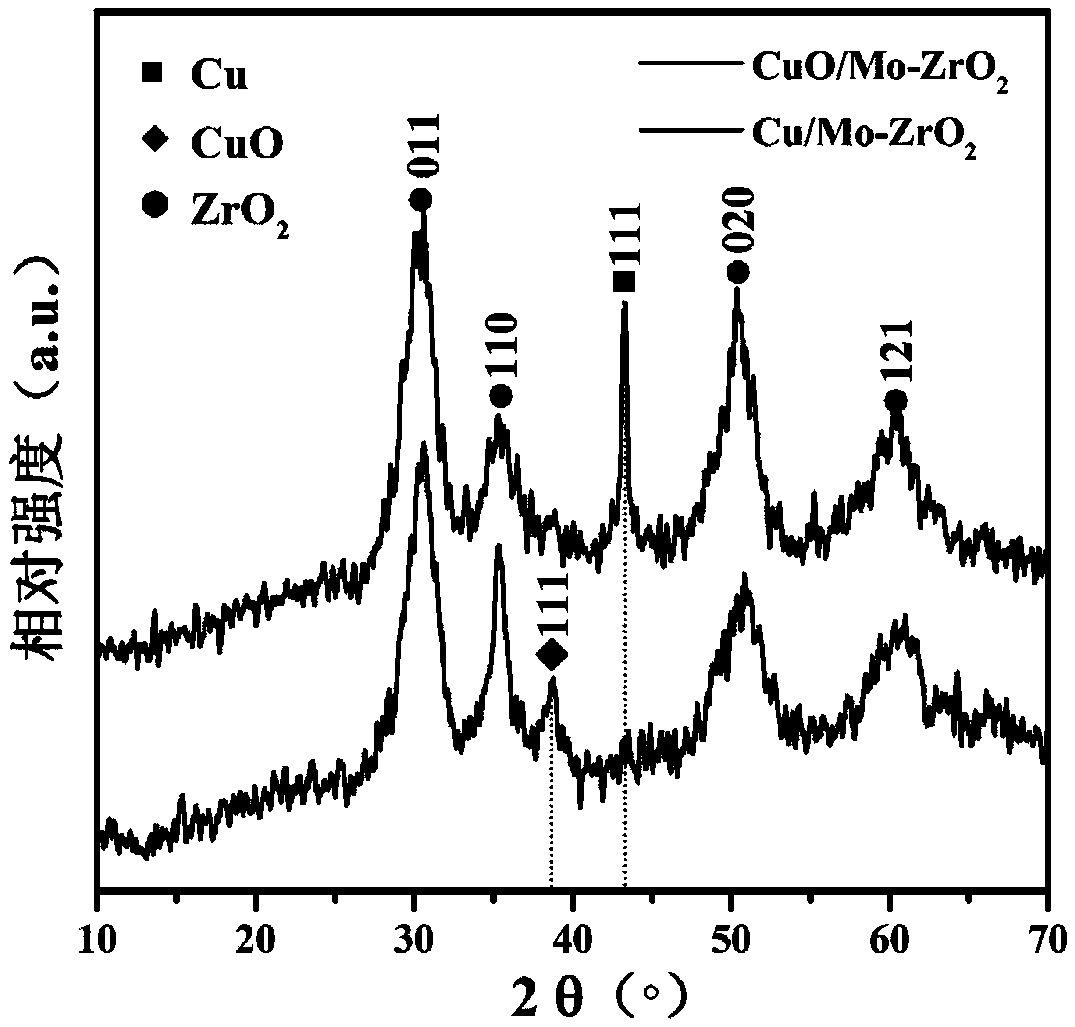

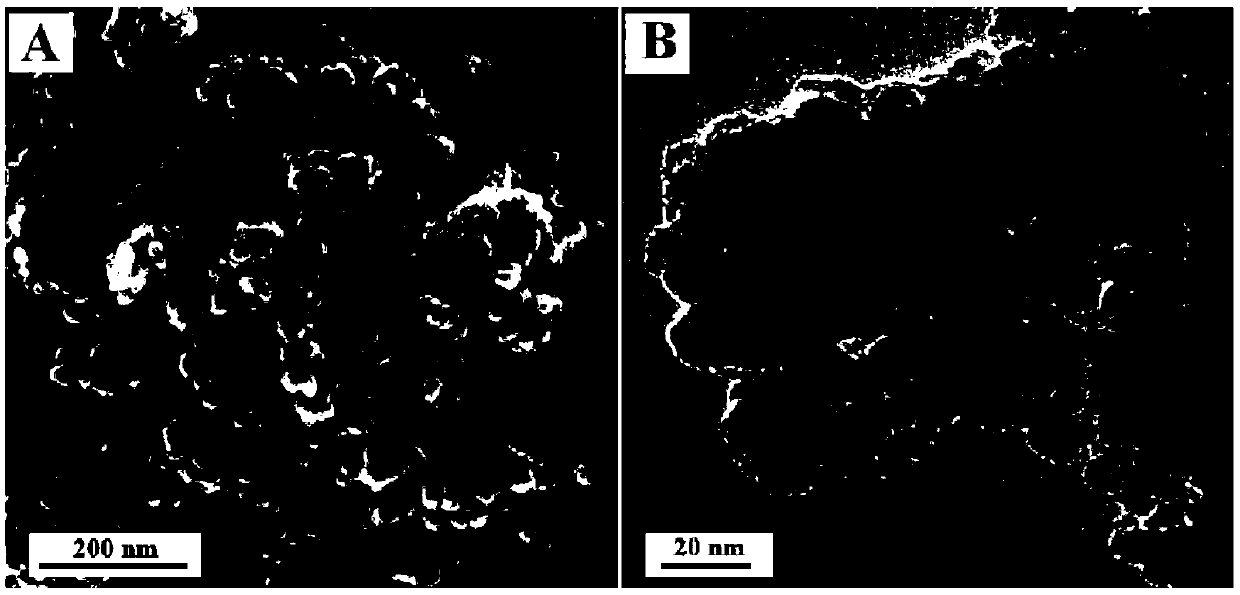

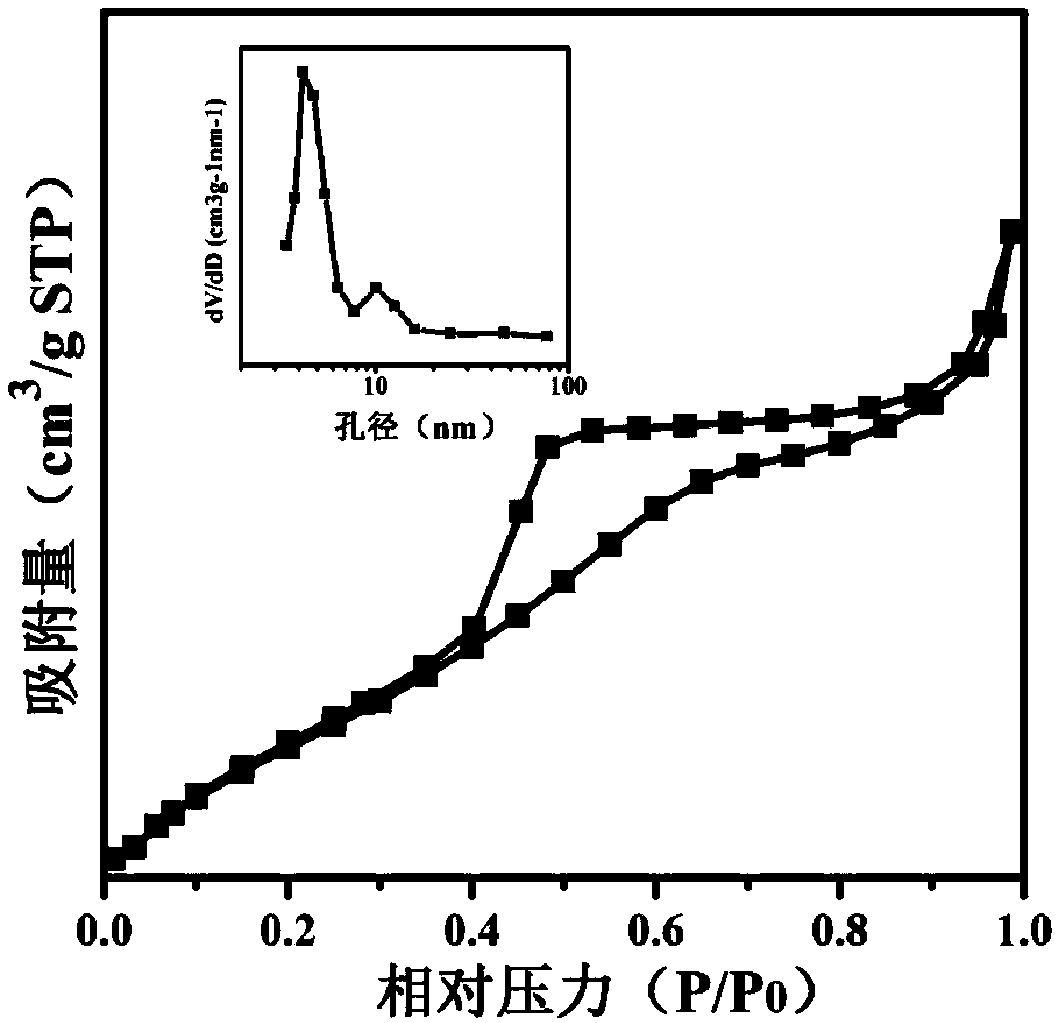

[0027] Weigh 3.86g zirconium nitrate Zr (NO 3 ) 4 ·5H 2 O, 0.18g ammonium molybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O, 2.03g copper nitrate Cu(NO 3 ) 2 ·3H 2 O, 0.30g of potassium chloride KCl, dissolved in 100ml of deionized water to prepare a salt solution. Weigh 4.75g sodium carbonate Na 2 CO 3 Dissolve in 100ml deionized water to prepare alkaline solution. Put the salt solution and alkali solution prepared above in a fully back-mixed rotary liquid film reactor at the same time, fully stir at a speed of 4000rpm for 4min, hydrothermally crystallize the obtained suspension at 70°C for 48h, and deionize the obtained precipitate Wash with water until the supernatant is neutral, then dry at 70°C for 12h. The obtained solid was roasted in a muffle furnace at a heating rate of 5 °C min -1, the temperature was raised from room temperature to 500° C., and then kept at constant temperature for 6 hours, and then calcined to obtain the catalyst precursor. with 10%H 2 / N 2 The...

Embodiment 2

[0031] Weigh 3.86g zirconium nitrate Zr (NO 3 ) 4 ·5H 2 O, 0.18g ammonium molybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O, 3.14g copper nitrate Cu(NO 3 ) 2 ·3H 2 O, 0.30g of potassium chloride KCl, dissolved in 100ml of deionized water to prepare a salt solution. Take by weighing 5.73g sodium carbonate solution Na 2 CO 3 Prepare an alkaline solution in 100ml deionized water. Put the salt solution and alkali solution prepared above in a fully back-mixed rotary liquid film reactor at the same time, fully stir at a speed of 4000rpm for 4min, hydrothermally crystallize the obtained suspension at 70°C for 60h, and deionize the obtained precipitate Wash with water until the supernatant is neutral, then dry at 70°C for 12h. The obtained solid was roasted in a muffle furnace at a heating rate of 5 °C min -1 , the temperature was raised from room temperature to 450° C., and then kept at constant temperature for 5 hours, and then calcined to obtain the catalyst precursor. with 10%H ...

Embodiment 3

[0034] Weigh 3.86g zirconium nitrate Zr (NO 3 ) 4 ·5H 2 O, 0.18g ammonium molybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O, 1.20g copper nitrate Cu(NO 3 ) 2 ·3H 2 O, 0.30g of potassium chloride KCl, dissolved in 100ml of deionized water to prepare a salt solution. Weigh 4.03g sodium carbonate Na 2 CO 3 Dissolve in 100ml deionized water to prepare alkaline solution. Put the salt solution and alkali solution prepared above in the fully back-mixed rotary liquid film reactor at the same time, fully stir at a speed of 5000rpm for 3min, hydrothermally crystallize the obtained suspension at 70°C for 72h, and deionize the obtained precipitate Wash with water until the supernatant is neutral, then dry at 70°C for 12h. The obtained solid was roasted in a muffle furnace at a heating rate of 3 °C min -1 , the temperature was raised from room temperature to 600° C., and then kept at a constant temperature for 5 hours, and then calcined to obtain the catalyst precursor. with 10%H 2 / N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com