A lead-free solder alloy and its application, glass component

A technology of lead-free solder alloy and lead-free solder, applied in the direction of welding/cutting medium/material, welding equipment, welding medium, etc., can solve the problems of inability to obtain high adhesive strength, poor plastic deformation characteristics, and inability to offset stress, etc. Achieve the effect of superior performance, little difference in performance, and small welding stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

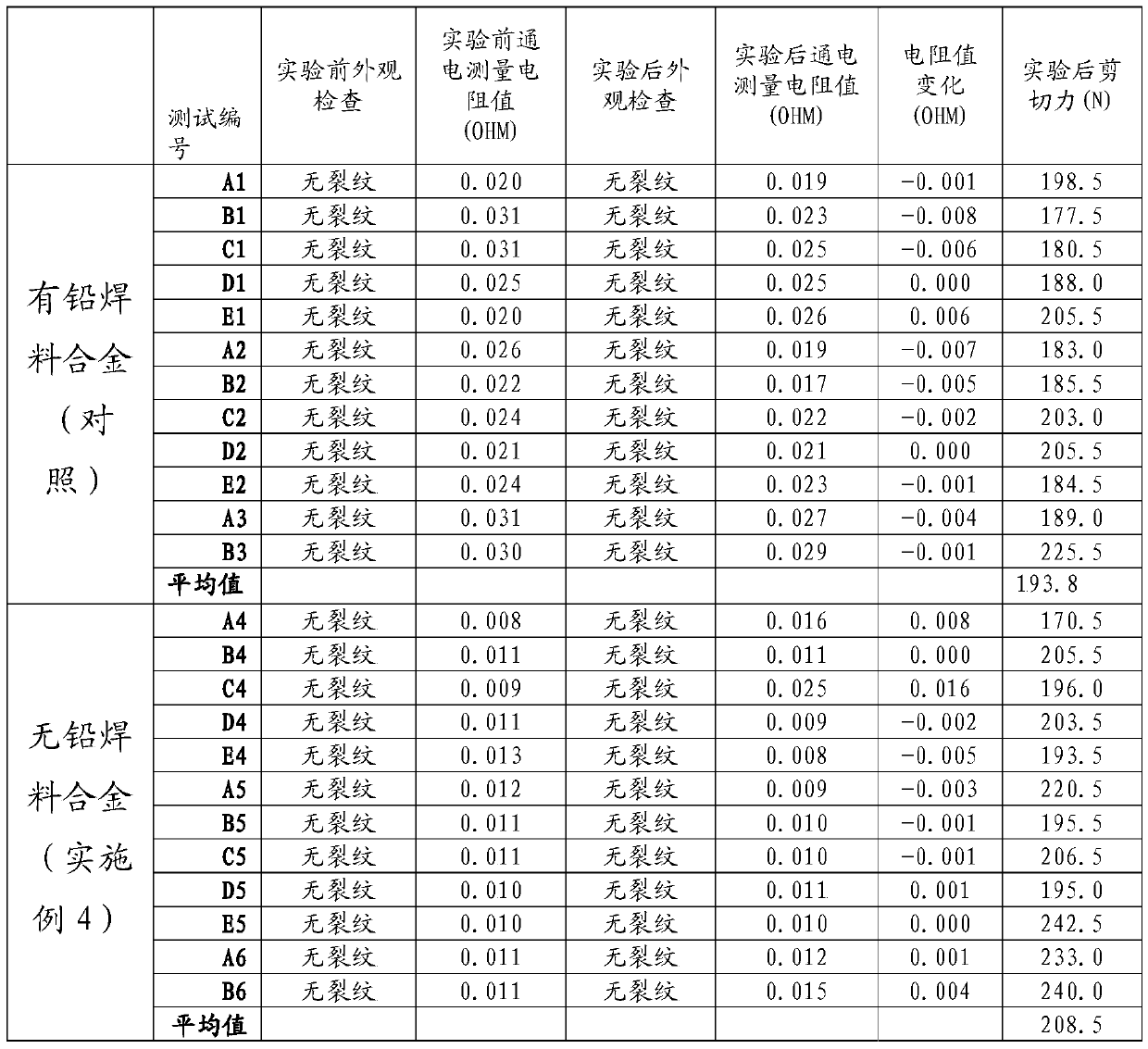

Embodiment 1

[0040] Components and mass percentages of the lead-free solder alloy of the present embodiment are:

[0041]Indium In: 63%, Silver Ag: 4.5%, Copper Cu: 0.5%, Iron Fe: 0.3%, Aluminum Al: 0.1%, and the balance is tin and unavoidable impurities.

[0042] The melting point or liquidus temperature of the above composition is 126.82°C, the solidus temperature is 113.40°C, and the Mohs hardness is 1-1.5.

Embodiment 2

[0044] Components and mass percentages of the lead-free solder alloy of the present embodiment are:

[0045] Indium In: 73.6%, silver Ag: 4.5%, copper Cu: 0.3%, and the balance is tin (about 21.6%) and unavoidable impurities.

[0046] The melting point or liquidus temperature of the lead-free solder alloy is 135.26°C, the solidus temperature is 122.24°C, and the Mohs hardness is 1-1.5.

Embodiment 3

[0048] Components and mass percentages of the lead-free solder alloy of the present embodiment are:

[0049] Indium In: 84.2%, silver Ag: 3.2%, copper Cu: 0.5%, iron Fe: 1.1%, and the balance is tin (about 11%) and unavoidable impurities.

[0050] The above-mentioned lead-free solder alloy has a melting point or a liquidus temperature of 140.01°C, a solidus temperature of 129.04°C, and a Mohs hardness of 1-1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com