Method for preparing boron carbide by utilizing gas-solid method

A boron carbide and gas-solid technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as difficult sintering density, uneven shape, large particle size, etc., and achieve high particle size distribution uniformity , The effect of excellent shape characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

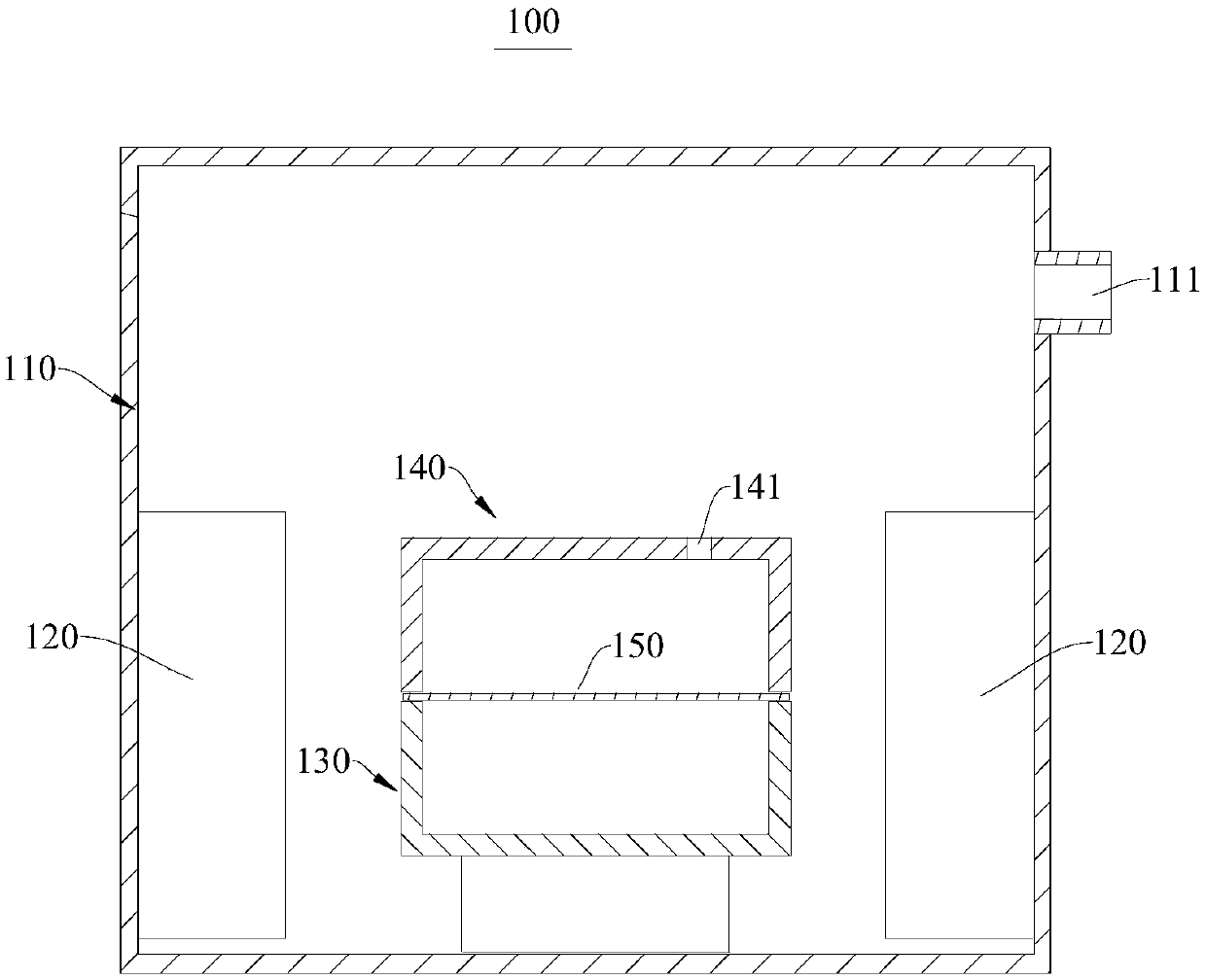

[0046] follow B 2 o 3 The mass ratio of / residual carbon is 40:1 Weigh boron oxide and graphene, boron oxide is placed in the first crucible 130, the graphite film 150 that has through hole is fixed on the first crucible 130, graphene is avoided Place the through hole on the graphite film 150, then place the second crucible 140 upside down on the first crucible 130, and use the wall edges of the first crucible 130 and the second crucible 140 to fix the graphite film 150 on the first crucible 130 and the second crucible Between 140.

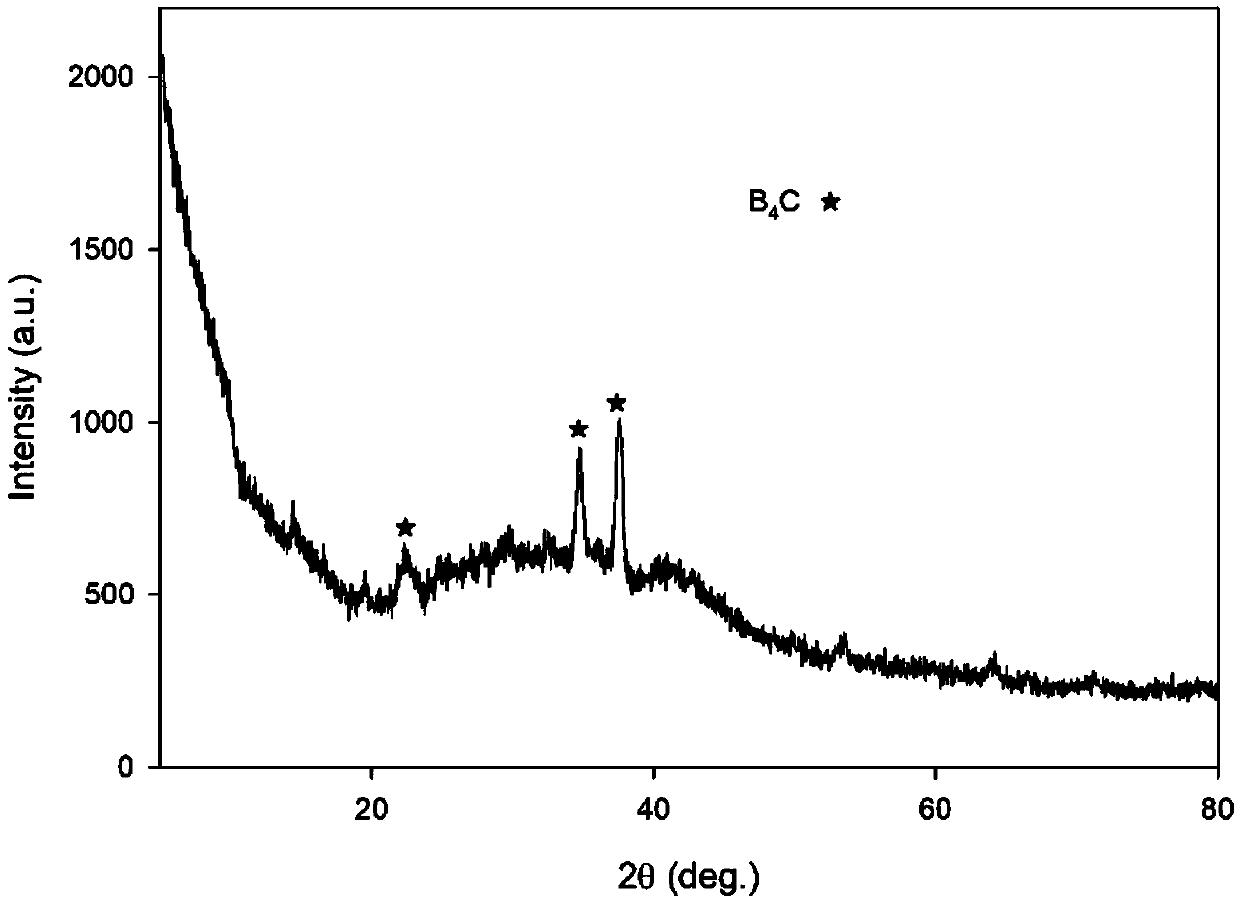

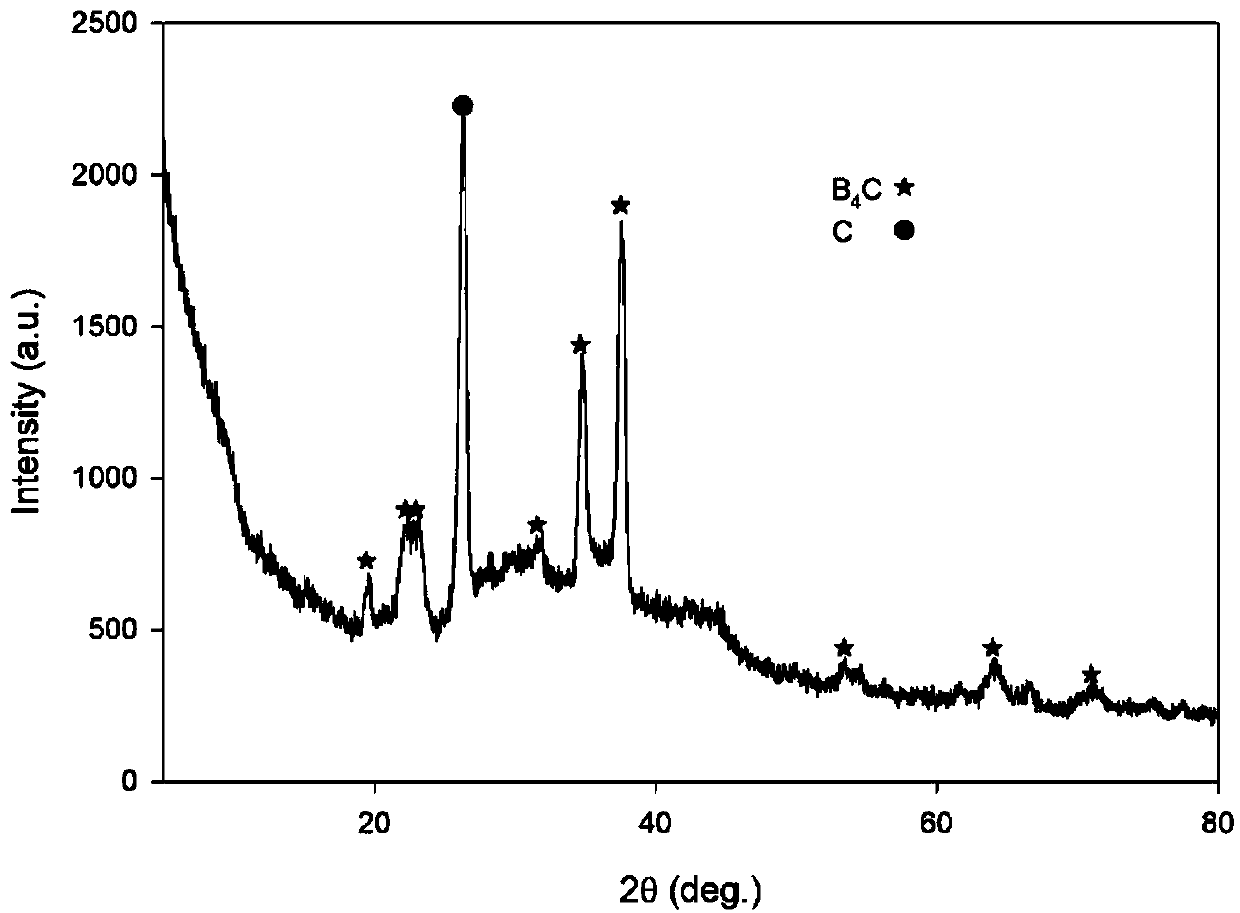

[0047] Vacuumize the vacuum atmosphere furnace 110, and then in a vacuum environment, turn on the vacuum atmosphere furnace 110 to make the graphite heating element 120 generate heat, and make the temperature in the vacuum atmosphere furnace 110 reach 1400°C at a heating rate of 10°C / min, and keep it warm for 6h Then cool down to room temperature to obtain boron carbide powder.

Embodiment 2

[0049] follow B 2 o 3 The mass ratio of / residual carbon is 20:1 Weigh boron oxide and phenolic resin, boron oxide is placed in the first crucible 130, the graphite film 150 with through hole is fixed on the first crucible 130, phenolic resin avoids Place the through hole on the graphite film 150, then place the second crucible 140 upside down on the first crucible 130, and use the wall edges of the first crucible 130 and the second crucible 140 to fix the graphite film 150 on the first crucible 130 and the second crucible Between 140.

[0050] Vacuumize the vacuum atmosphere furnace 110, and then in a vacuum environment, turn on the vacuum atmosphere furnace 110 to make the graphite heating element 120 generate heat, and make the temperature in the vacuum atmosphere furnace 110 reach 1500°C at a heating rate of 20°C / min, and keep it warm for 2 hours Then cool down to room temperature to obtain boron carbide powder.

Embodiment 3

[0052] follow B 2 o 3 The mass ratio of carbon / residual carbon is 60:1 Weighing boric acid and glucose, boric acid is placed in the first crucible 130, the graphite film 150 with through hole is fixed on the first crucible 130, glucose avoids through hole and is placed in Then place the second crucible 140 upside down on the first crucible 130, and use the wall edges of the first crucible 130 and the second crucible 140 to fix the graphite film 150 between the first crucible 130 and the second crucible 140.

[0053] Vacuumize the vacuum atmosphere furnace 110, and then in a vacuum environment, turn on the vacuum atmosphere furnace 110 to make the graphite heating element 120 generate heat, and make the temperature in the vacuum atmosphere furnace 110 reach 1500°C at a heating rate of 20°C / min, and keep it warm for 4h Then cool down to room temperature to obtain boron carbide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com