Dental pulp cavity gum 3D printing composite material preparation method and application thereof

A 3D printing and composite material technology, which is applied in the field of preparation of pulp cavity glue 3D printing composite materials, can solve the problems that 3D printing pulp cavity glue composite materials is rarely or rarely studied, and achieves high mosaic fit, The effect of increasing compatibility, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

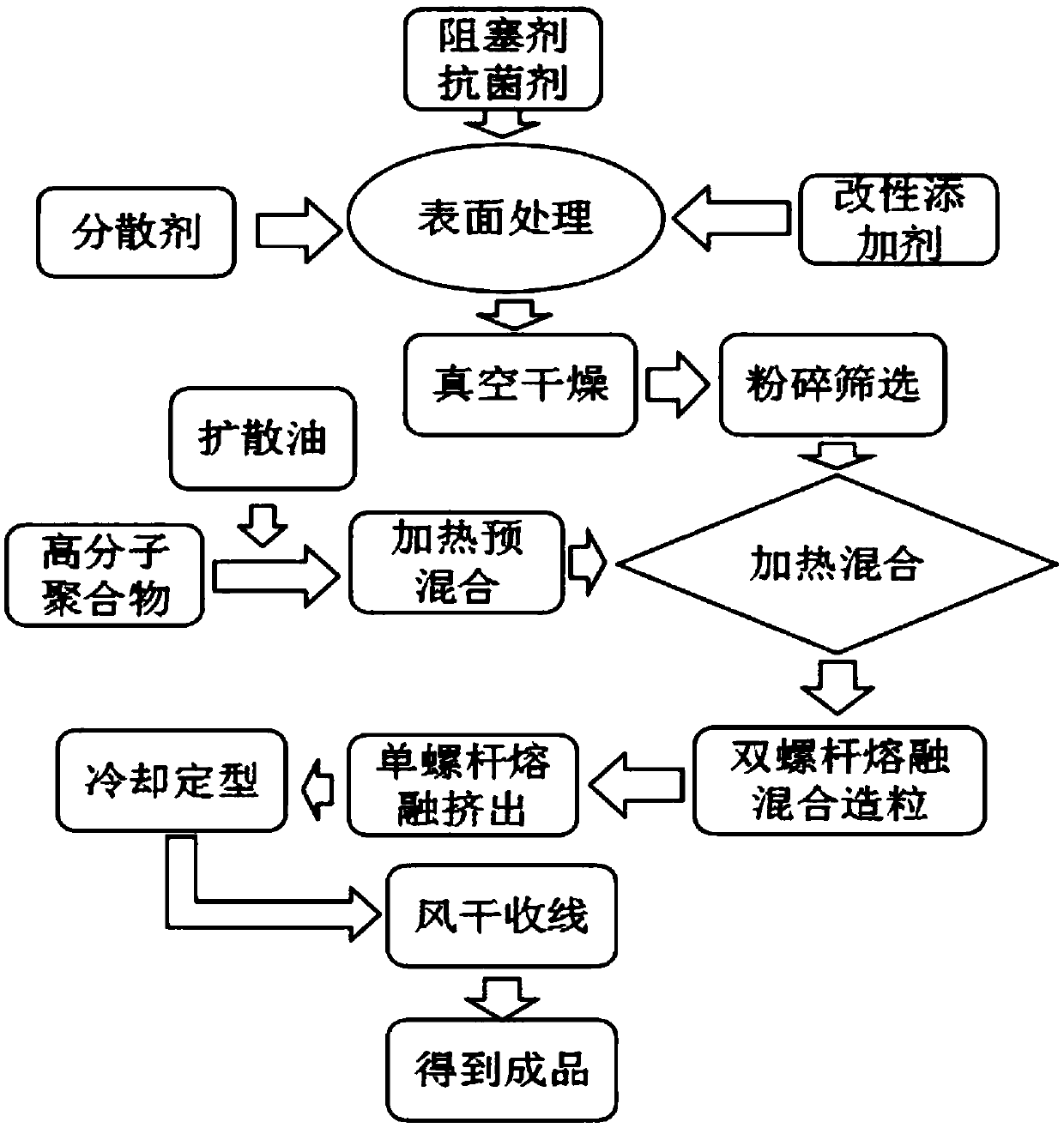

Method used

Image

Examples

Embodiment 2

[0042]

[0043]

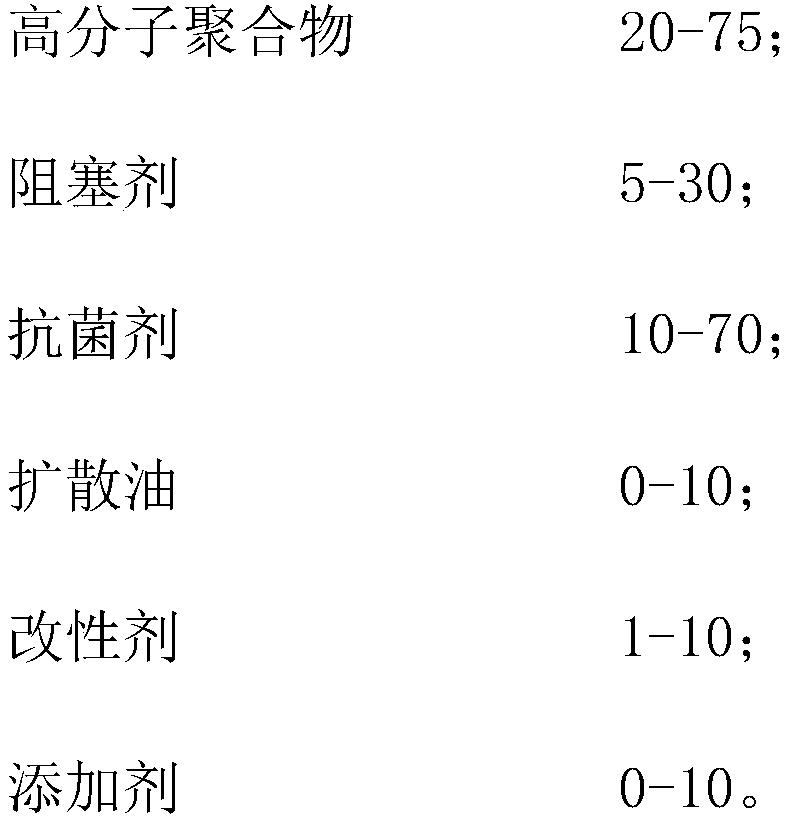

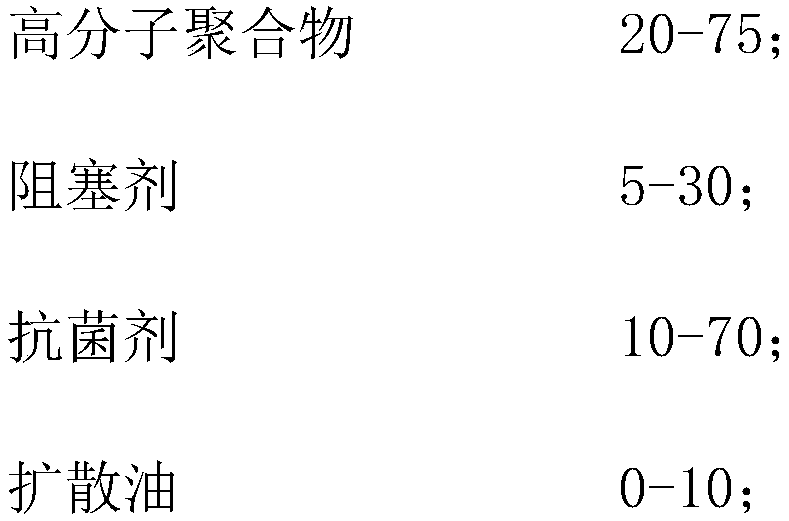

[0044] First, 25 parts by weight of ethanol and 2 parts by weight of rosin are added to the reaction vessel and stirred and dissolved, then 20 parts by weight of nano-barium sulfate particles and 25 parts by weight of nano-zinc oxide particles are added respectively, the pH value is set to 4, and the modification temperature is Surface treatment and modification under the conditions of 50°C, stirring speed of 100r / min and modification time of 25min to obtain a modified mixture, wash the mixture, and heat and bake in a vacuum dryer set at 55°C until dry , and then adopt the rotating speed to be set as, pulverizer of 2000r / min pulverizes, refines, and uses the sieve screening of more than 300 meshes, finally obtains the blocking agent antimicrobial agent mixture of the modification of more than 300 meshes; Secondly, 52 parts by weight of gutta-percha Add it to a high-speed heatable stirring mixer with a temperature set at 50°C and pre-mix evenly, with a ro...

Embodiment 3

[0047]

[0048] First, 25 parts by weight of ethanol and 2 parts by weight of rosin are added to the reaction vessel and stirred to dissolve, then 20 parts by weight of nano-barium sulfate particles and 20 parts by weight of nano-zinc oxide particles are added respectively, the pH value is set to 4, and the modification temperature is Surface treatment and modification under the conditions of 50°C, stirring speed of 100r / min and modification time of 25min to obtain a modified mixture, wash the mixture, and heat and bake in a vacuum dryer set at 55°C until dry , and then adopt the rotating speed to be set as, pulverizer of 2000r / min pulverizes, refines, and uses the sieve screening of more than 300 meshes, finally obtains the blocking agent antimicrobial agent mixture of the modification of more than 300 meshes; Secondly, 57 parts by weight of gutta-percha Add it to a high-speed heatable stirring mixer with a temperature set at 50°C and pre-mix evenly, with a rotation speed o...

Embodiment 4

[0051]

[0052] First, 25 parts by weight of ethanol and 2 parts by weight of rosin are added to the reaction vessel and stirred to dissolve, then 25 parts by weight of nano-barium sulfate particles and 20 parts by weight of nano-zinc oxide particles are added respectively, the pH value is set to 4, and the modification temperature is Surface treatment and modification under the conditions of 50°C, stirring speed of 100r / min and modification time of 25min to obtain a modified mixture, wash the mixture, and heat and bake in a vacuum dryer set at 55°C until dry , and then adopt the pulverizer that the rotating speed is set to 2000r / min to pulverize and refine, and use a sieve of more than 300 mesh to screen, finally obtain the modified blocking agent antibacterial agent mixture of more than 300 mesh; secondly, 52 parts by weight of polyurethane are added to the temperature Premix uniformly in a high-speed heatable stirring mixer set at 50°C, rotate at a speed of 600r / min, prem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com