Preparation method of WS2/graphene composite aerogel gas sensor

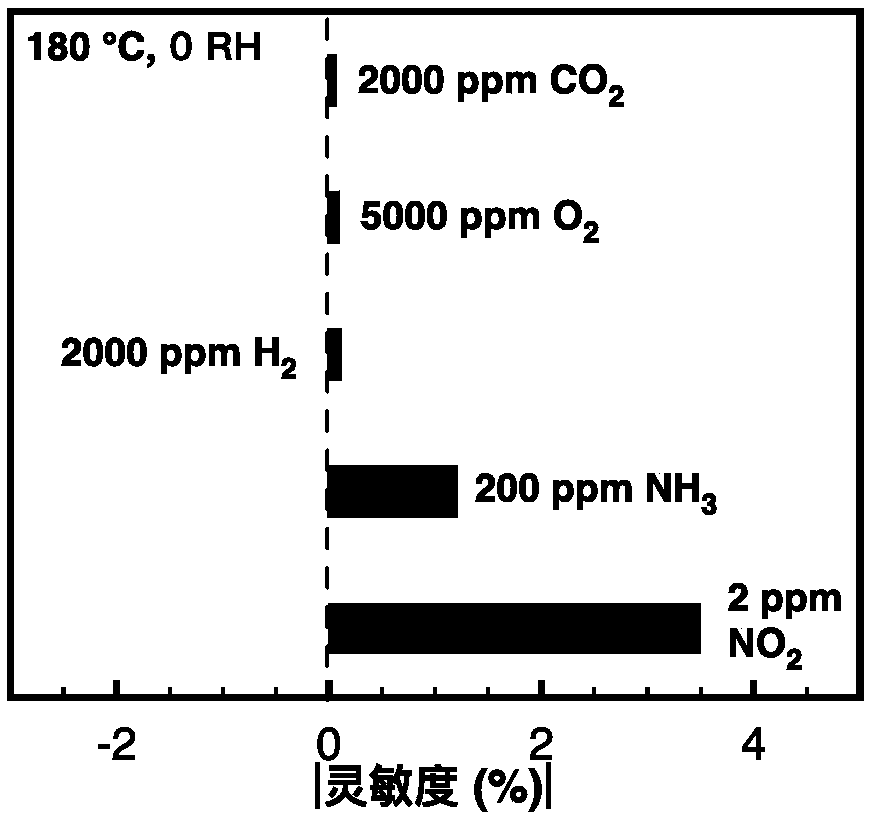

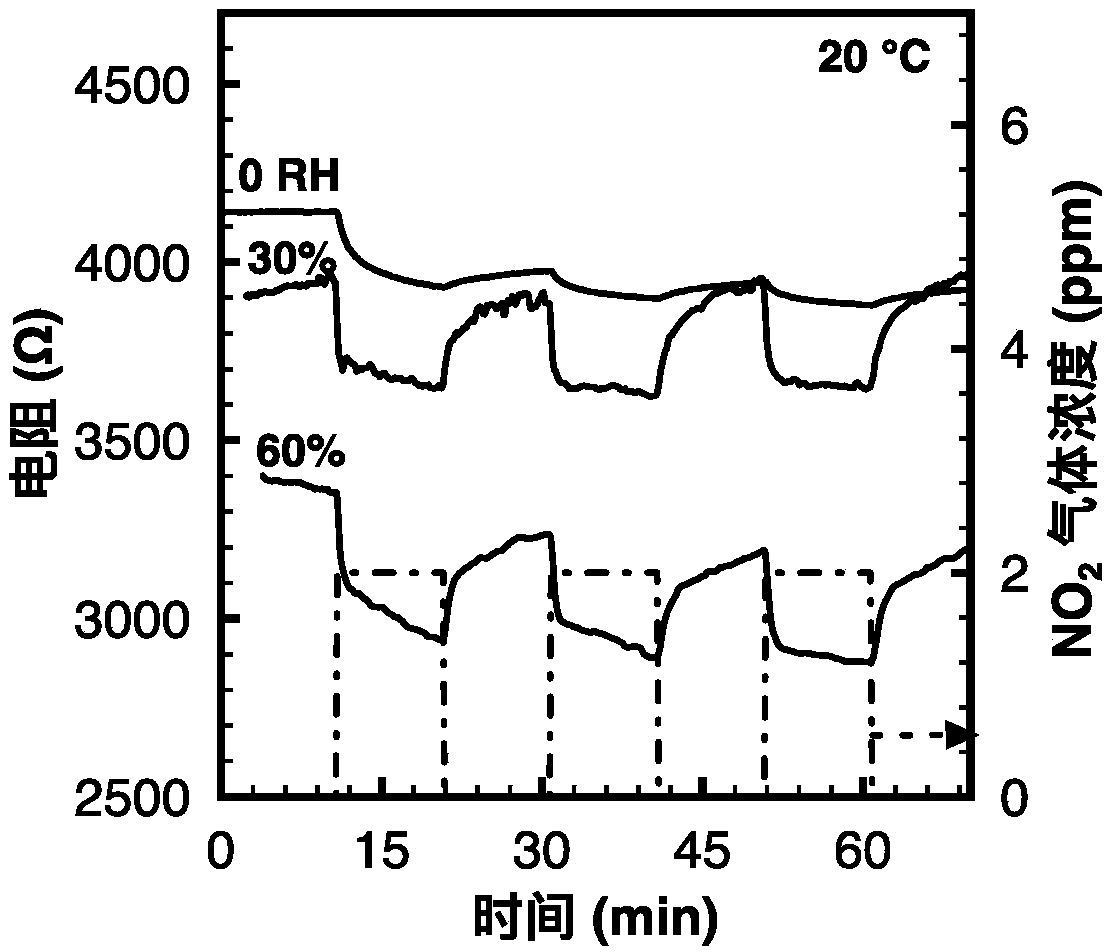

A graphene airgel and graphene composite technology, applied in the field of ultra-sensitive NO2 gas sensors, can solve the problems of incomplete recovery, poor selectivity of gas sensors, and limited practical applications, and achieve uniform temperature and humidity, good gas Sensitive performance, simple and repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

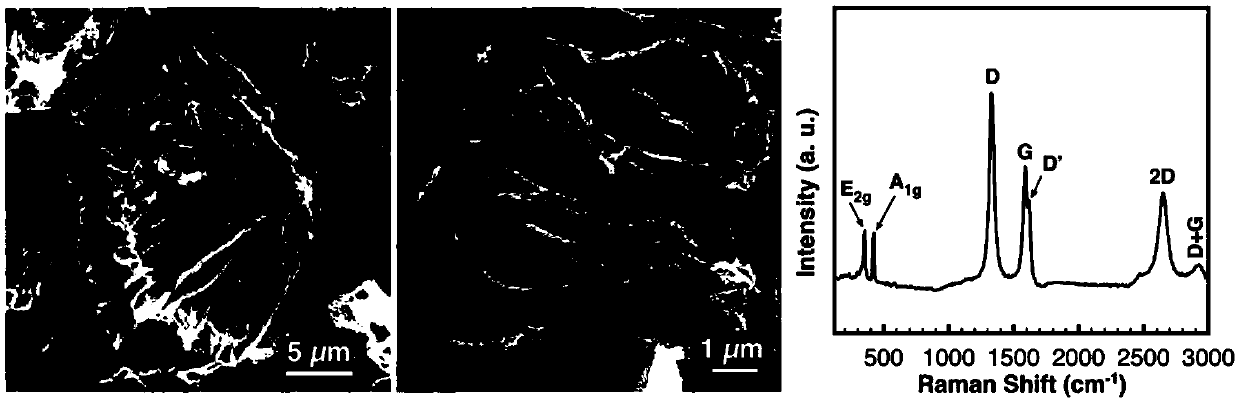

[0025] (1) Preparation of graphene aerogel. Add 3mL of graphene oxide aqueous solution with a mass concentration of 2% dropwise to 500μL of ammonia, place it in an oven at 85℃ for 12h to form a wet gel, then wash it several times with deionized water and acetone to remove the wet gel Residual ammonia in water; put the cleaned gel in N 2 The graphene aerogel was heat-treated at 1050°C for 3h in an atmosphere to obtain graphene aerogel; in order to improve the crystallinity of graphene, the obtained graphene aerogel was heat-treated at 2000°C for 1h in a He atmosphere.

[0026] (2)WS 2 / Graphene composite aerogel preparation. Disperse the graphene aerogel after two high temperature heat treatments to 1mol / L (NH 4 ) 2 (WS 4 ) Solution, place the mixed solution in liquid nitrogen to quickly freeze, freeze-dry the frozen liquid to form (NH 4 ) 2 (WS 4 ) Modified graphene aerogel. Will (NH 4 ) 2 (WS 4 ) The modified graphene aerogel is placed in a tube furnace at 2% H 2 / 98%Ar mixed a...

Embodiment 2

[0035] (1) Preparation of graphene aerogel. Add 3mL of graphene oxide aqueous solution with a mass concentration of 2% dropwise to 500μL of ammonia, place it in an oven at 80℃ for 10h to form a wet gel, then wash it several times with deionized water and acetone in turn to remove the wet gel Residual ammonia in water; put the cleaned gel in N 2 The graphene aerogel was heat-treated at 1000°C for 3h in an atmosphere to obtain graphene aerogel; in order to improve the crystallinity of graphene, the obtained graphene aerogel was heat-treated at 1500°C for 2h in a He atmosphere.

[0036] (2)WS 2 / Graphene composite aerogel preparation. Disperse the graphene aerogel after two high-temperature heat treatments to 0.8mol / L (NH 4 ) 2 (WS 4 ) Solution, put the mixed solution in liquid nitrogen to quickly freeze, freeze-dry the frozen liquid to form (NH 4 ) 2 (WS 4 ) Modified graphene aerogel. Will (NH 4 ) 2 (WS 4 ) The modified graphene aerogel is placed in a tube furnace at 3% H 2 / 97%Ar...

Embodiment 3

[0041] (1) Preparation of graphene aerogel. Slowly add 3 mL of graphene oxide aqueous solution with a mass concentration of 2% to 500 μL of ammonia water, place it in a 100 ℃ oven for 15 hours to form a wet gel, and then wash it several times with deionized water and acetone to remove the wet gel. Residual ammonia; put the cleaned gel in N 2 The graphene aerogel was heat-treated at 1100°C for 3h in an atmosphere; in order to improve the crystallinity of graphene, the obtained graphene aerogel was heat-treated at 1800°C for 1.5h in a He atmosphere.

[0042] (2)WS 2 / Graphene composite aerogel preparation. Disperse the graphene aerogel after two high temperature heat treatments to 0.9mol / L (NH 4 ) 2 (WS 4 ) Solution, put the mixed solution in liquid nitrogen to quickly freeze, freeze-dry the frozen liquid to form (NH 4 ) 2 (WS 4 ) Modified graphene aerogel. Will (NH 4 ) 2 (WS 4 ) The modified graphene aerogel is placed in a tube furnace at 5% H 2 / 95%Ar mixed atmosphere at 720℃ he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com