Diamond grinding disk and preparation process thereof

A preparation process and diamond technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of diamond cutter head or grinding block continuous brazing type diamond grinding disc debris clogging processing efficiency and noise, etc. Achieve high binding force, avoid inaccurate precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

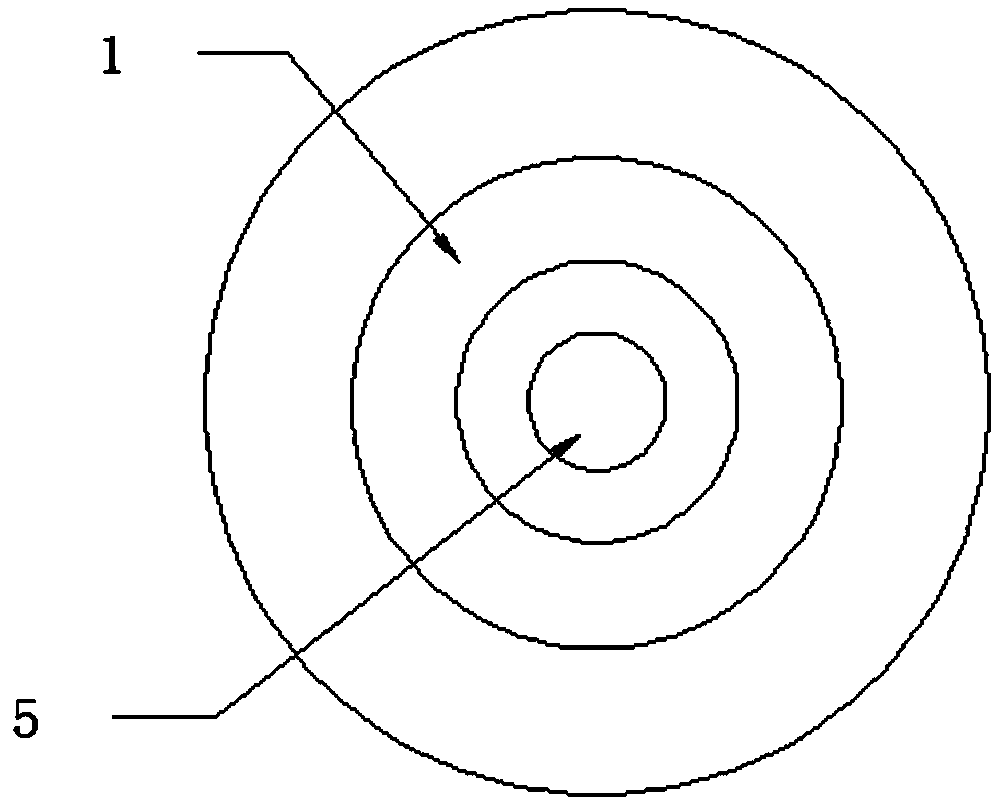

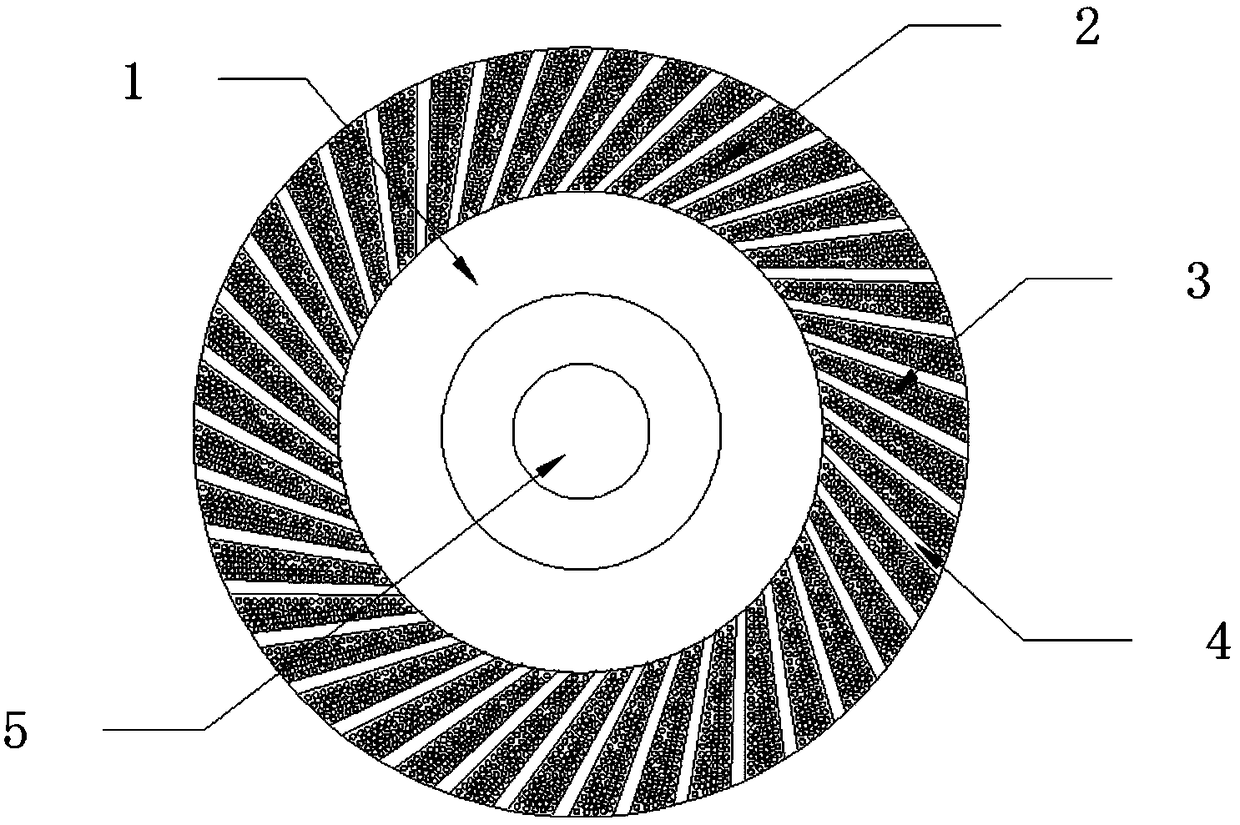

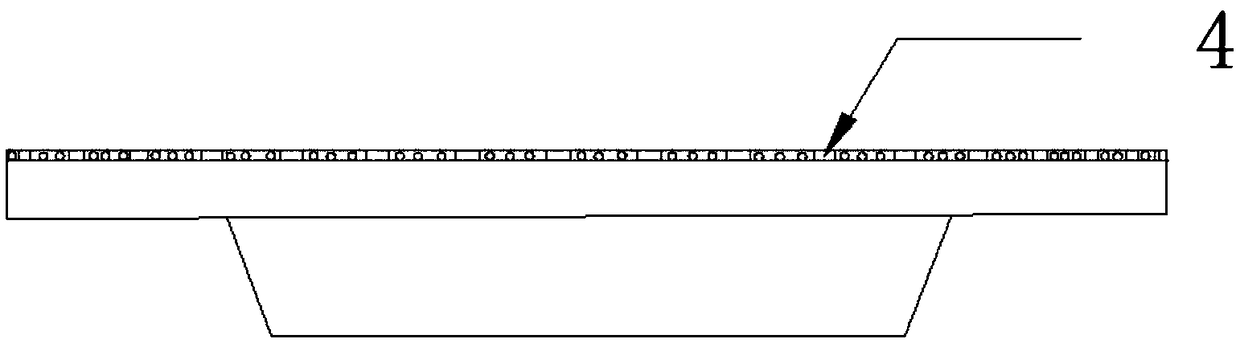

[0021] Such as figure 2 As shown, a diamond grinding disc includes a grinding disc substrate 1 , diamond abrasive grains 2 , brazing material 3 , groove 4 , and a circular fixing hole 5 . A circular fixing hole 5 is arranged in the center of the grinding disc substrate 1 of the diamond grinding disc. The surface of the grinding disc base 1 is fixed with diamond abrasive grains 2 by brazing; the diamond particles 2 on the surface of the grinding disc base 1 are arranged geometrically and directionally by means of ultraviolet light curing; the working surface of the grinding disc base is provided with multiple grooves 4 with chip removal and heat dissipation functions .

[0022] The preparation process is as follows: weigh 100 g of thermoplastic resin adhesive and ethanol diluent according to the mass ratio of 5:1, mix well, apply the mixed solution evenly on the working surface of the grinding disc base 1, and let it stand for 15 minutes. Stick the treated grinding disc base...

Embodiment 2

[0024] Such as Figure 4 As shown, a diamond grinding disc includes a grinding disc substrate 1, diamond abrasive grains 2, brazing material 3, grooves 4, and six symmetrical circular fixing holes 6. The surface of the disc substrate 1 is fixed with diamond abrasive grains 2 by brazing; the diamond particles on the surface of the disc substrate 1 are arranged geometrically and directionally by means of ultraviolet light curing, and the working surface of the disc substrate is provided with multiple grooves 4 with chip removal and heat dissipation functions.

[0025] The preparation process is as follows: Weigh 100g of thermoplastic resin adhesive and ethanol diluent according to the mass ratio of 6:1, mix thoroughly, apply the mixed solution evenly on the working surface of the grinding disc base 1, and let it stand for 20 minutes. Stick the treated grinding disc base 1 in the copper-based brazing material granules to form the copper-based brazing material 3 base layer; , sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com