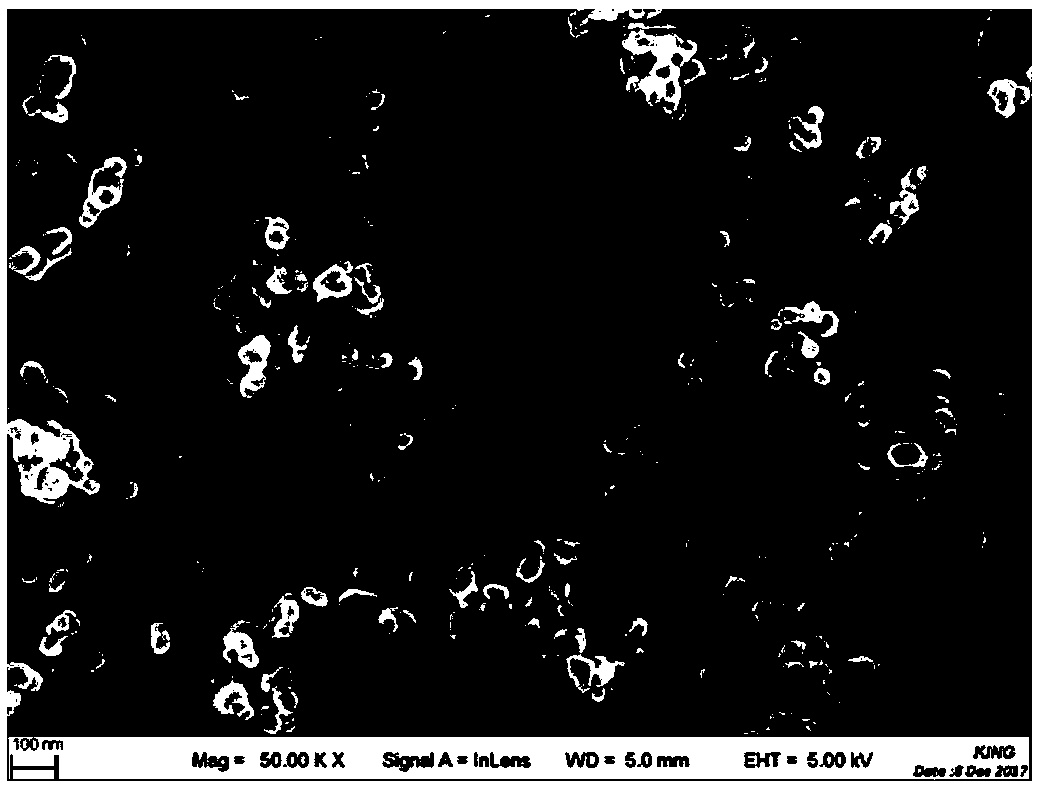

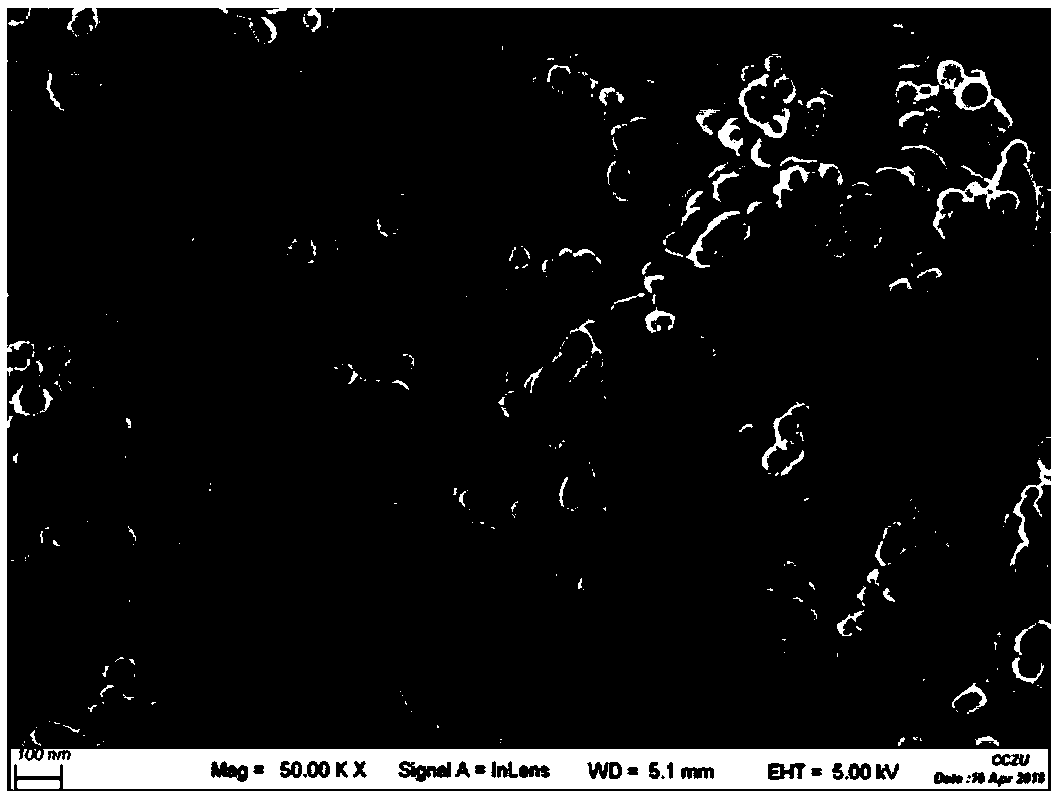

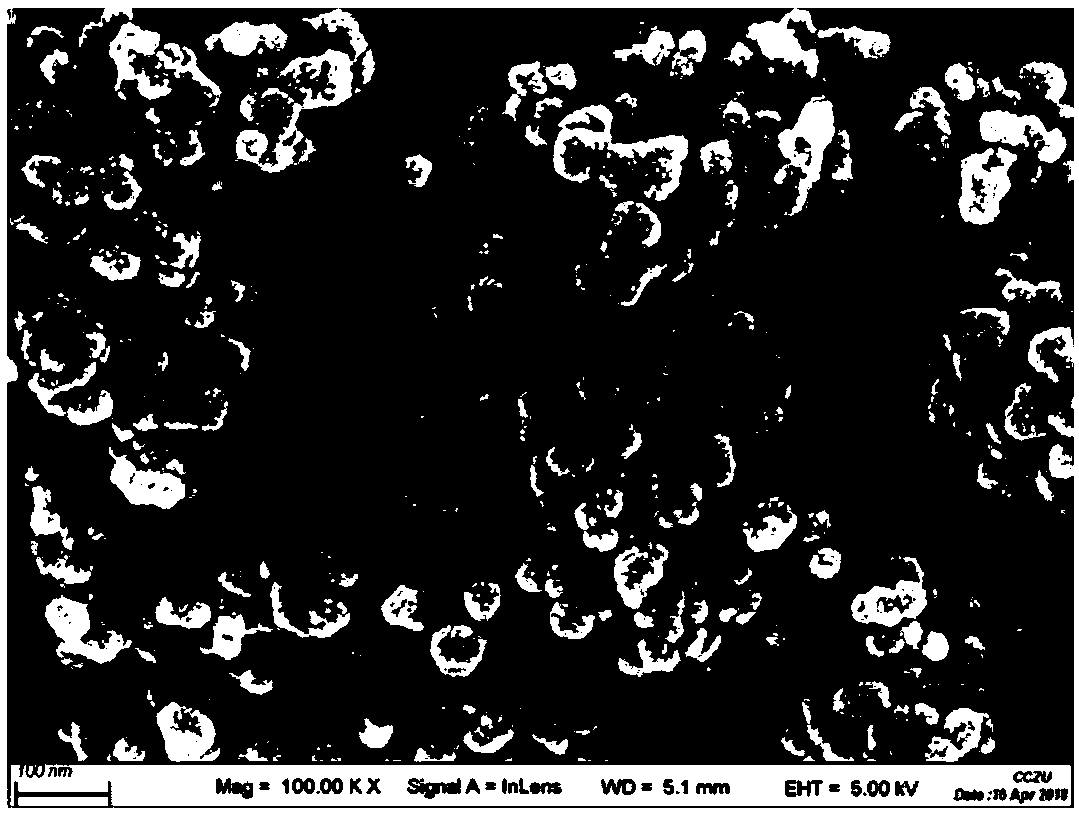

Preparation method of nano gadolinium oxide powder with large specific surface area

A technology of nano-gadolinium oxide and large specific surface area, which is applied in nanotechnology, chemical instruments and methods, nanotechnology, etc. for materials and surface science. Small and other problems, to achieve the effect of preventing agglomeration, uniform distribution, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of nano gadolinium oxide powder with large specific surface area, comprising the following steps:

[0042] (1) Prepare gadolinium-containing inorganic salt solution: take 68.97L of 1.6mol / L gadolinium chloride solution (20kg of gadolinium oxide) and put it into a reaction tank, add 482.8L deionized water, and prepare a chloride solution with a concentration of 0.2mol / L Gadolinium solution;

[0043] (2) Get dehydrated alcohol: 1kg respectively, polyethylene glycol 2000: 0.3kg, sodium dodecylbenzenesulfonate: 0.3kg, add polyethylene glycol 2000 and sodium dodecylbenzenesulfonate respectively without Fully stir in water and ethanol to prepare surfactant;

[0044] (3) The prepared surfactant is added in the gadolinium chloride solution, fully mixed to uniform;

[0045] (4) Take 0.8kg of sodium carbonate, add 7.55L of deionized water to fully dissolve it, and prepare a 1mol / L sodium carbonate solution, add the sodium carbonate solution to the gadoliniu...

Embodiment 2

[0051] (1) Prepare gadolinium-containing inorganic salt solution: take 68.97L of 1.6mol / L gadolinium chloride solution (gadolinium oxide 20kg) and put it into a reaction tank, add 298.9L deionized water to prepare a 0.3mol / L gadolinium chloride solution ;

[0052] (2) Take absolute ethanol: 1kg, polyethylene glycol 2000: 0.4kg, sodium dodecylbenzenesulfonate: 0.2kg respectively, add polyethylene glycol 2000 and sodium dodecylbenzenesulfonate respectively without Fully stir in water and ethanol to prepare surfactant;

[0053] (3) The prepared surfactant is added in the gadolinium chloride solution, fully mixed to uniform;

[0054] (4) Take 0.8kg of sodium carbonate, add 15.1L of deionized water to fully dissolve, and prepare a 0.5mol / L sodium carbonate solution, add the sodium carbonate solution to the gadolinium chloride solution at a flow rate of 0.5L / min, and adjust the pH value to 4;

[0055] (5) Take 7.2kg of high-purity sodium hydroxide powder, add 600L deionized water...

Embodiment 3

[0060] (1) Preparation of gadolinium-containing inorganic salt solution: take 68.97L of 1.6mol / L gadolinium nitrate solution (20kg of gadolinium oxide) and put it into a reaction tank, add 551.7L of deionized water, and prepare a 0.2mol / L gadolinium chloride solution;

[0061] (2) Take absolute ethanol: 1kg, polyethylene glycol 2000: 0.3kg, sodium dodecylbenzenesulfonate: 0.2kg respectively, add polyethylene glycol 2000 and sodium dodecylbenzenesulfonate respectively without Fully stir in water and ethanol to prepare surfactant;

[0062] (3) The prepared surfactant is added in the gadolinium chloride solution, fully mixed to uniform;

[0063] (4) Take 0.8kg of sodium carbonate, add 9.43L of deionized water to fully dissolve, and prepare a 0.8mol / L sodium carbonate solution, add the sodium carbonate solution to the gadolinium chloride solution at a flow rate of 0.5L / min, and adjust the pH value to 4;

[0064] (5) Take 7.2kg of high-purity sodium hydroxide powder, add 600L dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com