Polybenzoxazine airgel thermal insulation material and preparation method thereof

A technology of polybenzoxazine and benzoxazine is applied in the field of thermal insulation materials to achieve the effects of small pore size, low thermal conductivity and low moisture absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

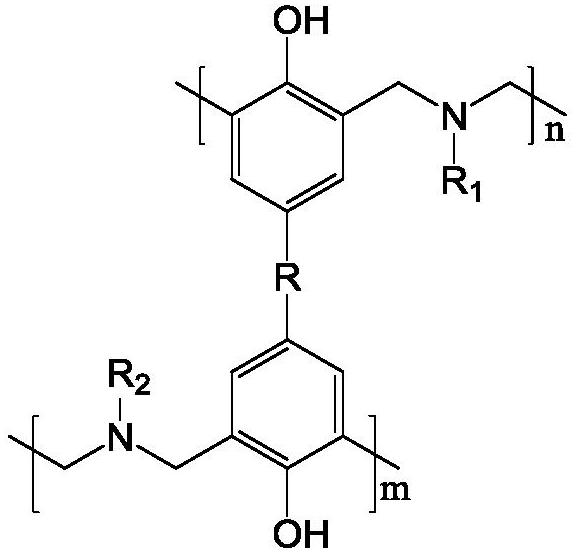

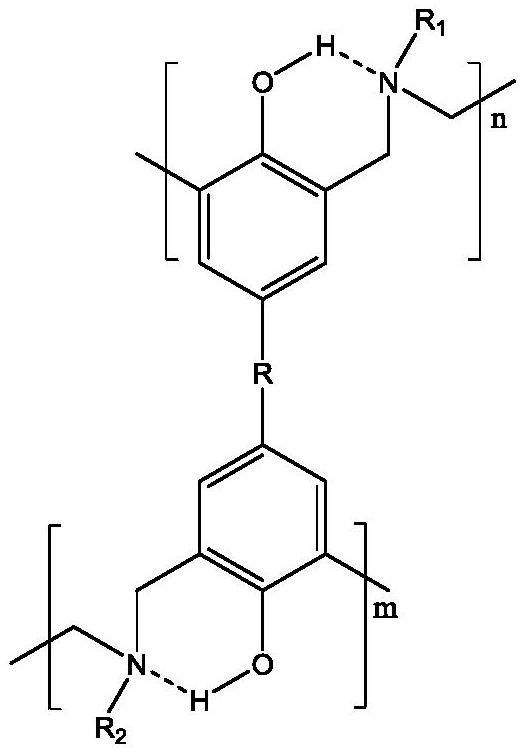

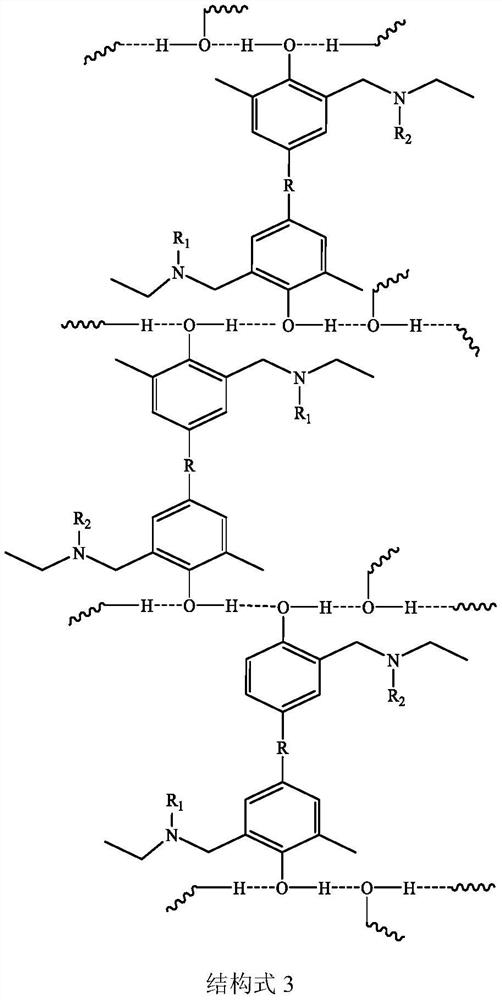

Method used

Image

Examples

Embodiment 1

[0034] In the first step, the BO-1 benzoxazine monomer shown in formula I is dissolved in a DMF solvent, stirred until completely dissolved, and a clear and transparent benzoxazine monomer solution with a concentration of 0.05 g / ml is obtained;

[0035] In the second step, hydrochloric acid is added as a catalyst to the benzoxazine monomer solution obtained in the first step, the reaction temperature is 10°C, and the reaction is stirred for 20 minutes to obtain polybenzoxazine sol, wherein hydrochloric acid and monomer The molar ratio is 1:1;

[0036] In the third step, the polybenzoxazine sol obtained in the second step is poured into a container, sealed and left to stand, and polybenzoxazine gel is obtained after 25 hours, and the obtained polybenzoxazine gel is dissolved in DMF solvent After medium aging for 36 hours, the solvent was replaced three times with anhydrous acetone, once every 12 hours, to obtain the polybenzoxazine gel after solvent replacement;

[0037] In th...

Embodiment 2

[0041] In the first step, the BO-2 benzoxazine monomer represented by formula II is dissolved in NMP solvent, stirred until completely dissolved, and a clear and transparent benzoxazine monomer solution with a concentration of 0.20 g / ml is obtained;

[0042] In the second step, oxalic acid is added as a catalyst to the benzoxazine monomer solution obtained in the first step, the reaction temperature is 20°C, and the reaction is stirred for 10 minutes to obtain polybenzoxazine sol, in which oxalic acid and monomer are added The molar ratio is 2:1;

[0043] In the third step, pour the sol obtained in the second step into a container, seal it and let it stand, and obtain a polybenzoxazine gel after 10 hours, and age the obtained polybenzoxazine gel in NMP solvent for 36 hours , using absolute ethanol to perform solvent replacement three times, replacing once every 12 hours, to obtain a polybenzoxazine gel after solvent replacement;

[0044] In the fourth step, the solvent-substi...

Embodiment 3

[0048] In the first step, the BO-3 benzoxazine monomer represented by formula III is dissolved in DMSO solvent, stirred until completely dissolved, and a clear and transparent benzoxazine monomer solution with a concentration of 0.30 g / ml is obtained;

[0049] In the second step, nitric acid is added as a catalyst to the benzoxazine monomer solution obtained in the first step, the reaction temperature is 50°C, and the reaction is stirred for 30 minutes to obtain polybenzoxazine sol, wherein nitric acid and monomer are added The molar ratio is 1.5:1;

[0050] In the third step, the sol obtained in the second step is poured into a container, sealed and left to stand, and polybenzoxazine gel is obtained after 4 hours, and the obtained polybenzoxazine gel is aged in DMSO solvent for 24 hours , using anhydrous acetone to perform solvent replacement three times, replacing once every 8 hours, to obtain a polybenzoxazine gel after solvent replacement;

[0051] In the fourth step, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com