Excavating blade, excavating tool and method for manufacturing excavating blade

A blade and tool technology, applied in the field of excavation tools and excavation blade manufacturing, can solve the problems of easy cracking, poor thermal expansion coefficient, insufficient wear resistance and defect resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

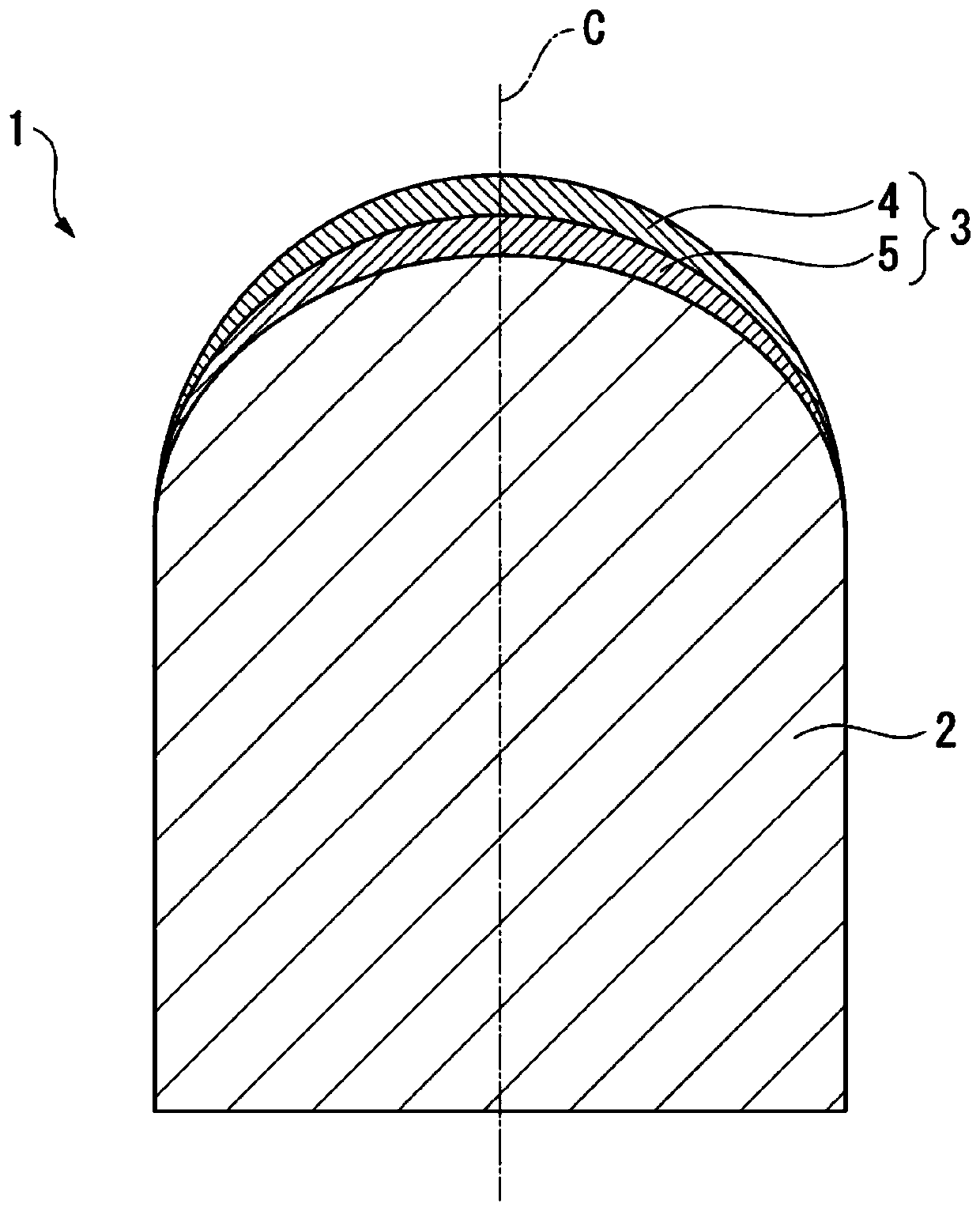

[0092] First, as Example 1, an example of a cBN sintered body constituting the outermost layer was given to demonstrate the effects of the present invention.

[0093] Using cBN particles having a median diameter (D50) shown in Table 1 as a substrate, an AlN film having an average film thickness shown in Table 1 was coated on the cBN particles by the ALD method. Specifically, first, cBN particles were put into a furnace, and the temperature in the furnace was raised to 350°C. Next, as a film-forming gas, Al(CH 3 ) 3 Gas and NH as reactive gas 3 gas, and the following (1) to (4) are regarded as one cycle, and this cycle is repeated until the AlN film reaches the target film thickness.

[0094] (1)Ar+Al(CH 3 ) 3 Gas inflow process

[0095] (2) Ar gas purging process

[0096] (3)Ar+NH 3 Gas inflow process

[0097] (4) Ar gas purging process

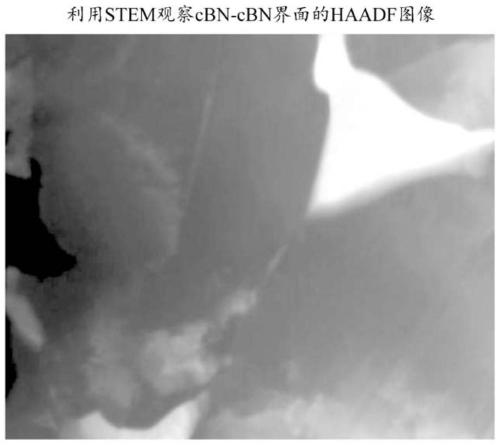

[0098] The cBN particles were observed by SEM, and it was confirmed that the surface of the cBN particles was coated with an AlN f...

Embodiment 2

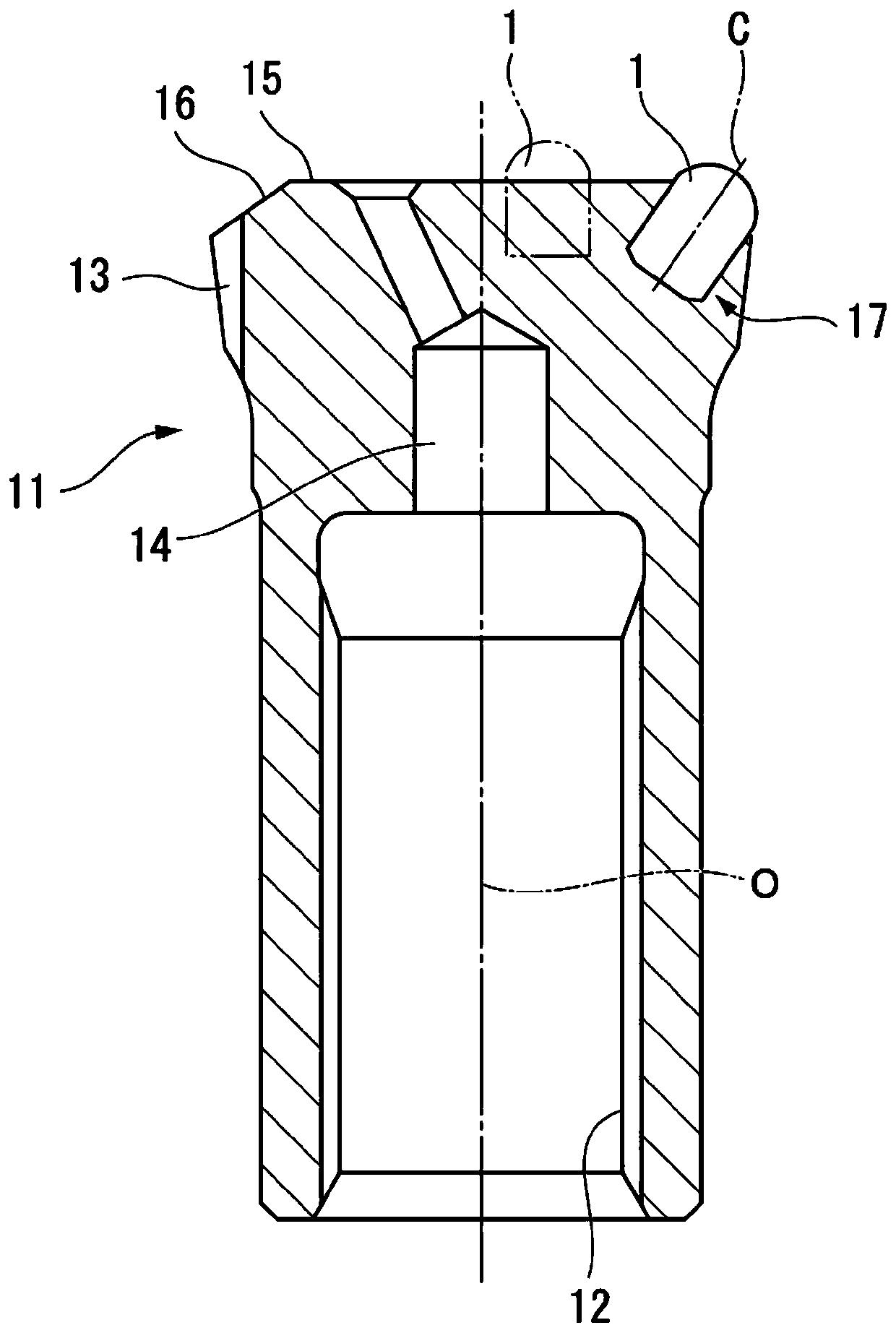

[0121] Next, an example in which the above-mentioned cBN sintered body is applied to an excavating blade of the outermost layer is given as Example 2 to demonstrate the effect of the present invention.

[0122] The powder of cBN particles with a particle size of 4.1 μm after the same pretreatment as in Example 1, the raw material powder of the binder phase, that is, TiN powder with a particle size of 0.5 μm, Al powder with a particle size of 0.3 μm, and Al powder with a particle size of 0.5 μm. TiAl 3 The powder and the cBN particle powder content when the total amount of the WC powder with a particle size of 0.8 μm is regarded as 100% by volume were blended so that the ratios in Table 7 were obtained, wet mixing was carried out, and then dried. In this way, the raw material powders of the outermost layers of Examples 1 to 4 of the present invention were obtained. The non-pretreated cBN powder with a particle size of 9.6 μm, the W powder with a particle size of 4 μm, the Al p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com