Refluxing improved rectifying tower for 2-cyanopyrazine

A cyanopyrazine and rectifying tower technology, which is applied in the directions of fractionation, distillation separation, distillation adjustment/control, etc., can solve the problems of insufficient utilization rate of trays, reflux purification efficiency, etc., to improve the purification effect, improve the overall efficiency, and improve the distribution The effect of a large flow coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

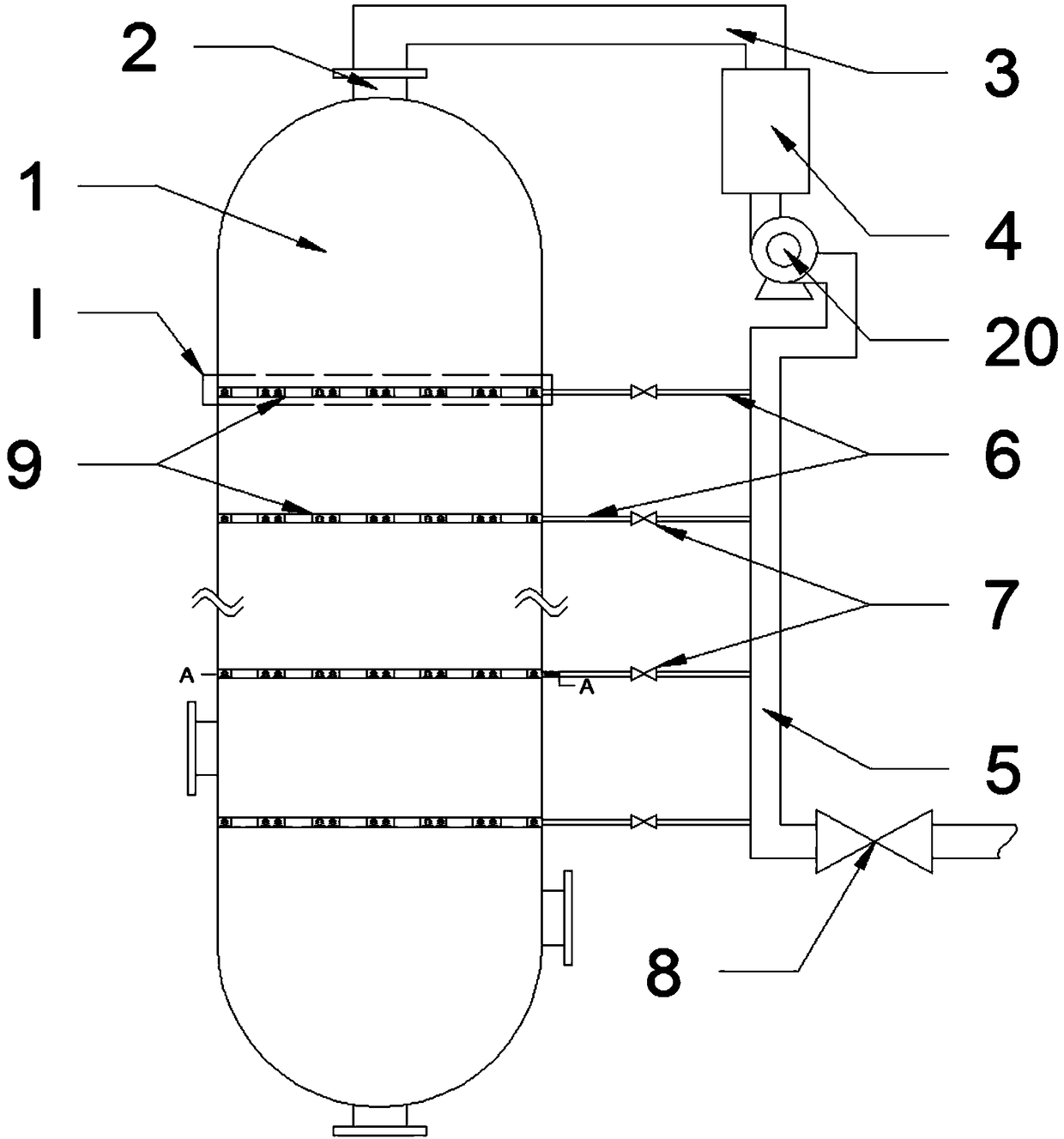

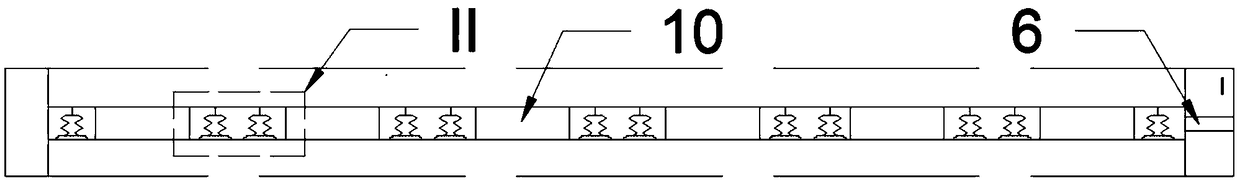

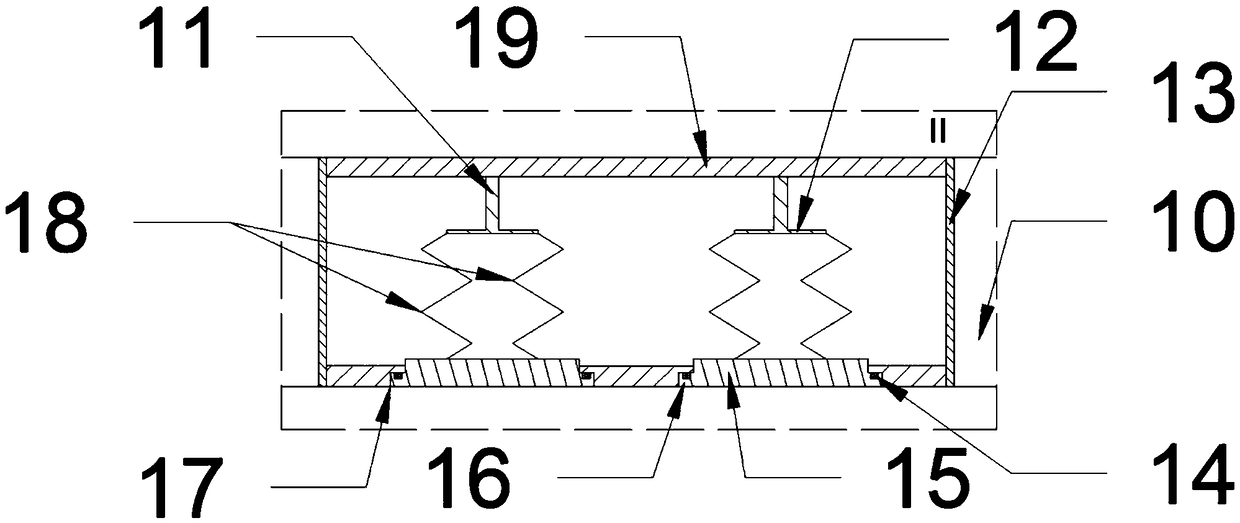

[0039] A rectification tower for reflux improved 2-cyanopyrazine, comprising a tower body 1 whose top is arranged in a production hole 2, a plurality of trays 9 arranged inside the tower body 1 and a reflux system connected to the tower body 1 The reflux system includes a production pipe 3 connected to the production hole 2, a heat exchanger 4 connected to the production pipe 3 and a reflux main pipe 5 connected to the heat exchanger 4; the tray 9 includes a hollow structure The housing 19, several sieve holes 10 provided on the housing 19 and passing through the housing 19, several spray holes 17 provided in the non-screen 10 area of the bottom surface of the housing 19; the side of the tray 9 is provided with There is a return auxiliary pipe 6 that communicates with the inside of the housing 19 and extends to the outside of the tower body 1; each of the return auxiliary pipes 6 communicates with the return main pipe 5 and is provided with an auxiliary pipe valve 7; each of ...

Embodiment 2

[0043] Based on Embodiment 1, in order to facilitate the maintenance of the trays and improve the reusability of the trays, the following improvements are made: the sealing ring 13 and the housing 19 are fixedly connected by an interference fit. Compared with welding, the sealing ring 13 is fixed by interference fit. When fouling occurs inside the tray 9, the sealing ring 13 can be riveted out for corresponding treatment. The removal of the sealing ring 13 by means of riveting can ensure the structural integrity of the tray 9 to the greatest extent, and the sealing ring 13 can be reassembled after the maintenance is completed. In this way, the reusability of the tray 9 can be greatly improved, thereby greatly saving the use and maintenance costs of the tray 9 .

Embodiment 3

[0045] Based on Example 1, in order to speed up the injection speed of the rectified fraction and increase the distribution coverage area, the following improvements have been made: each of the spray holes 17 is provided with a valve body assembly; The fixed rod 11 at the top of the inner wall of the body 19, the spray valve plate 15 installed in the spray hole 17 and the spring 18 arranged between the fixed rod 11 and the spray valve plate 15; There is a sliding fit between the holes 17 . By arranging the valve body assembly at the spray hole 17, its function is as follows: First, the internal pressure of the tray 9 can be further increased through the sealing effect of the valve body assembly, thereby enhancing the flow rate of the feed liquid when it is sprayed from the spray hole 17. spray state, so that it is easier to atomize after spraying, and then improve the initial mass transfer and heat transfer efficiency again; secondly, through the annular gap formed between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com