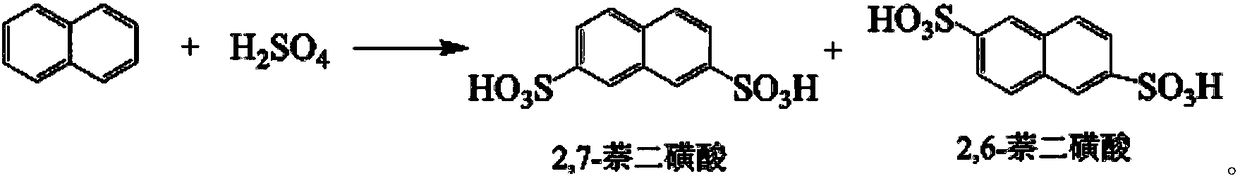

Method of synthesizing, purifying and refining 2,6-naphthalene disulfonic acid

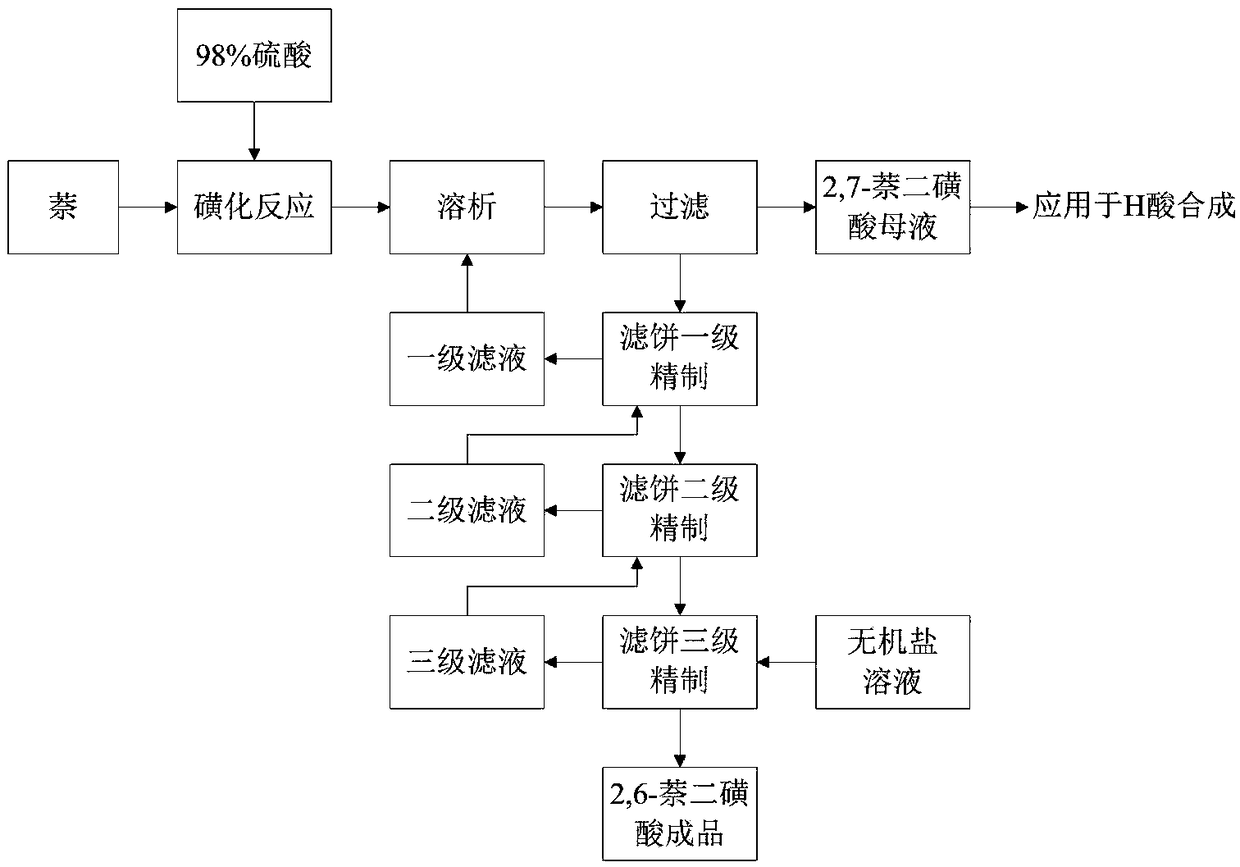

A technology of naphthalene disulfonic acid and refined naphthalene is applied in the preparation of sulfonic acid, chemical instruments and methods, preparation of organic compounds, etc., and can solve the requirements that high-quality products cannot be achieved, the requirements for the use of sodium chloride are high, and the solubility of sodium sulfate Low problems, to achieve the effect of saving waste liquid treatment costs, solving waste liquid discharge, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Sulfonation, dissolution

[0030] Add 1000Kg of refined naphthalene to the reaction kettle, slowly add 3828.13Kg of concentrated sulfuric acid, raise the temperature to 175°C, keep the temperature for 5h, and cool down to 80°C after the reaction.

[0031] Add 805.80Kg water to the sulfonated material, control the dropping time for 1.5h, stir for 2h after the dropping is completed, filter and separate to obtain a filter cake with a hundred weight of 647.61Kg mainly 2,6-naphthalene disulfonic acid, in which Contains 79.21% of 2,6-naphthalene disulfonic acid and 13.29% of 2,7-naphthalene disulfonic acid.

[0032] 2) washing

[0033] Add 2609.46Kg of ammonium sulfate solution (ammonium sulfate mass content 27.27%) into the reaction kettle, add 647.61Kg of 2,6-naphthalene disulfonic acid-based filter cake under stirring, stir for 2 hours, and filter to obtain The grade 1 filter cake based on 2,6-naphthalene disulfonic acid weighs 632.18Kg, and the grade 1 refined filtra...

Embodiment 1a

[0035] 1) Sulfonation, dissolution

[0036] Add 1000Kg of refined naphthalene to the reaction kettle, slowly add 3828.13Kg of concentrated sulfuric acid, raise the temperature to 175°C, keep the temperature for 5h, and cool down to 80°C after the reaction. Add the primary refined filtrate 1488.69Kg (which contains 20.65% of 2,6-naphthalene disulfonic acid and 60.23% of 2,7-naphthalene disulfonic acid) that embodiment 1 obtains in the sulfonated material, control the dropping time 1.5 h, stirred for 2 hours after the dropwise addition, filtered and separated to obtain a filter cake based on 654.94Kg of 2,6-naphthalene disulfonic acid in percent weight, wherein the filter cake contained 81.12% of 2,6-naphthalene disulfonic acid and 10.76% 2,7-naphthalene disulfonic acid, the first-stage refined filtrate used in the separation of sulfonated products can effectively recover 51.52% of 2,7-naphthalene disulfonic acid in the filter cake, so that the final yield of 2,7-naphthalene dis...

Embodiment 2

[0040] 1) Sulfonation, dissolution

[0041] Add 1000Kg of refined naphthalene to the reaction kettle, slowly add 3828.13Kg of concentrated sulfuric acid, raise the temperature to 165°C, keep the temperature for 6.5h, and cool down to 90°C after the reaction.

[0042] Add 805.80Kg of water to the sulfonated material, control the dropwise addition time for 2h, stir for 2h after the dropwise addition, and filter and separate to obtain a filter cake based on 2,6-naphthalene disulfonic acid with a hundredth weight of 651.22Kg. The filter cake contains 78.88% of 2,6-naphthalene disulfonic acid and 13.49% of 2,7-naphthalene disulfonic acid.

[0043] 2) washing

[0044] Add 2544.30Kg of ammonia solution (mass content: 17%) into the reaction kettle, add 651.22Kg of 2,6-naphthalene disulfonic acid-based filter cake under stirring, stir for 2 hours, and filter to obtain grade 2 , 6-naphthalene disulfonic acid-based filter cake, 100% weight 634.52Kg, first grade refined filtrate 1160.60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com