A preparation method of flexible zinc-air battery based on zeolite imidazolate skeleton-67 derivatives

A zeolite imidazolate and air battery technology, which is applied to fuel cell half-cells and primary battery half-cells, battery electrodes, circuits, etc., can solve problems such as poor wearability, difficulty in providing, and large discharge current, and achieve The effect of enriching catalytic sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a flexible zinc-air battery based on zeolite imidazolate skeleton-67 (ZIF-67) derivatives, comprising steps as follows:

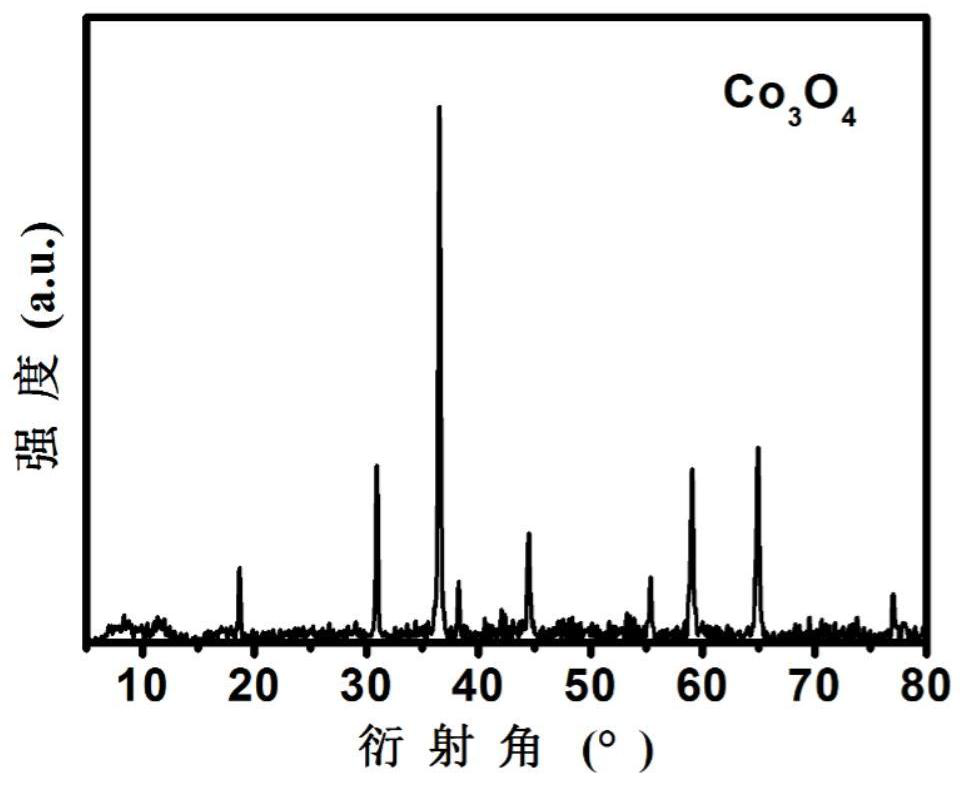

[0039] (1) Positive electrode: Using zeolite imidazolate framework-67 (ZIF-67) as raw material, it was annealed at 400°C for 5 hours in an air atmosphere to obtain Co 3 o 4 Catalyst (such as figure 1 shown). Using the prepared Co 3 o 4 An air electrode with a thickness of 1 mm was fabricated.

[0040] (2) Electrolyte: A: Take 4g of agar and add 40ml of deionized water, stir magnetically in a water bath at 80°C until completely dissolved. B: Prepare 6M KOH solution. Slowly add 20ml of B solution into A under magnetic stirring, and stir for 2h. Cool at room temperature to obtain a gel solid electrolyte, and control the thickness of the solid electrolyte to 1 mm.

[0041] (3) Negative electrode: Cut a metal zinc sheet with a thickness of 0.3 mm into a zinc sheet with a length of 5 cm and a width of 0.6 cm. Select a metal ...

Embodiment 2

[0045] A method for preparing a flexible zinc-air battery based on zeolite imidazolate skeleton-67 (ZIF-67) derivatives, comprising steps as follows:

[0046] (1) Positive electrode: Using zeolite imidazolate framework-67 (ZIF-67) as raw material, it was annealed at 300°C for 3 hours in an air atmosphere to obtain Co 3 o 4 positive catalyst. Using the prepared Co 3 o 4 An air electrode with a thickness of 2 mm was fabricated.

[0047] (2) Electrolyte: A: Take 5g of agar and add 50ml of deionized water, and magnetically stir in a water bath at 80°C until completely dissolved. B: Prepare 6M NH 4 Cl solution. Slowly add 30ml of B solution into A under magnetic stirring, and stir for 1h. Cool at room temperature to obtain a gel solid electrolyte, and control the thickness of the solid electrolyte to 1 mm.

[0048] (3) Negative electrode: Cut a metal zinc sheet with a thickness of 0.5 mm into a zinc sheet with a length of 5 cm and a width of 1 cm. Choose a metal wire with ...

Embodiment 3

[0052] A method for preparing a flexible zinc-air battery based on zeolite imidazolate skeleton-67 (ZIF-67) derivatives, comprising steps as follows:

[0053] (1) Positive electrode: using zeolite imidazolate framework-67 (ZIF-67) as raw material, annealing at 600°C for 3 hours in air atmosphere to obtain Co 3 o 4 positive catalyst. Using the prepared Co 3 o 4 An air electrode with a thickness of 2 mm was fabricated.

[0054] (2) Electrolyte: A: Add 4g of agar to 40ml of deionized water, and magnetically stir in a water bath at 90°C until completely dissolved. B: Prepare 3M KOH solution. Slowly add 30ml of B solution into A under magnetic stirring, and stir for 1h. Cool at room temperature to obtain a gel solid electrolyte, and control the thickness of the solid electrolyte to 1.5 mm.

[0055] (3) Negative electrode: Cut a metal zinc sheet with a thickness of 0.5 mm into a zinc sheet with a length of 5 cm and a width of 1 cm. Select a metal wire with a diameter of 1mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com