amorphous co x mn y the w 4 Preparation method and application of activated carbon composite catalytic material

A technology for catalytic materials and composite materials, applied in the field of preparation of amorphous CoxMnyWO4/activated carbon composite catalytic materials, can solve the problems of complex preparation process and high cost of raw materials, and achieve the effect of high catalytic efficiency and wide industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

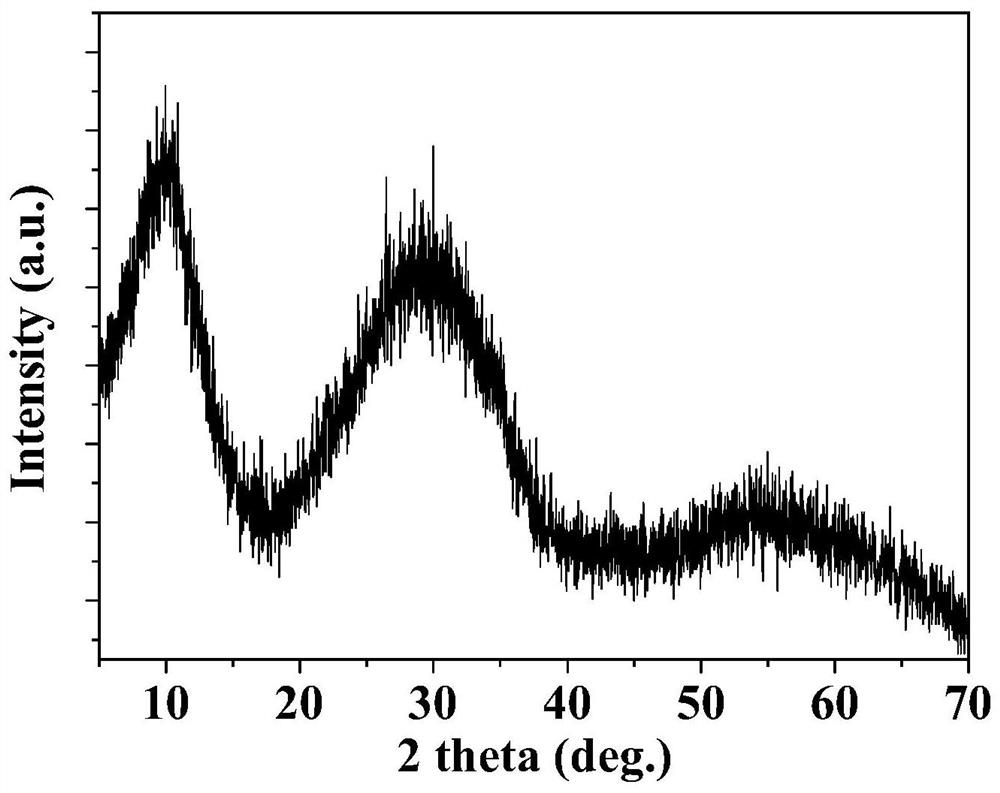

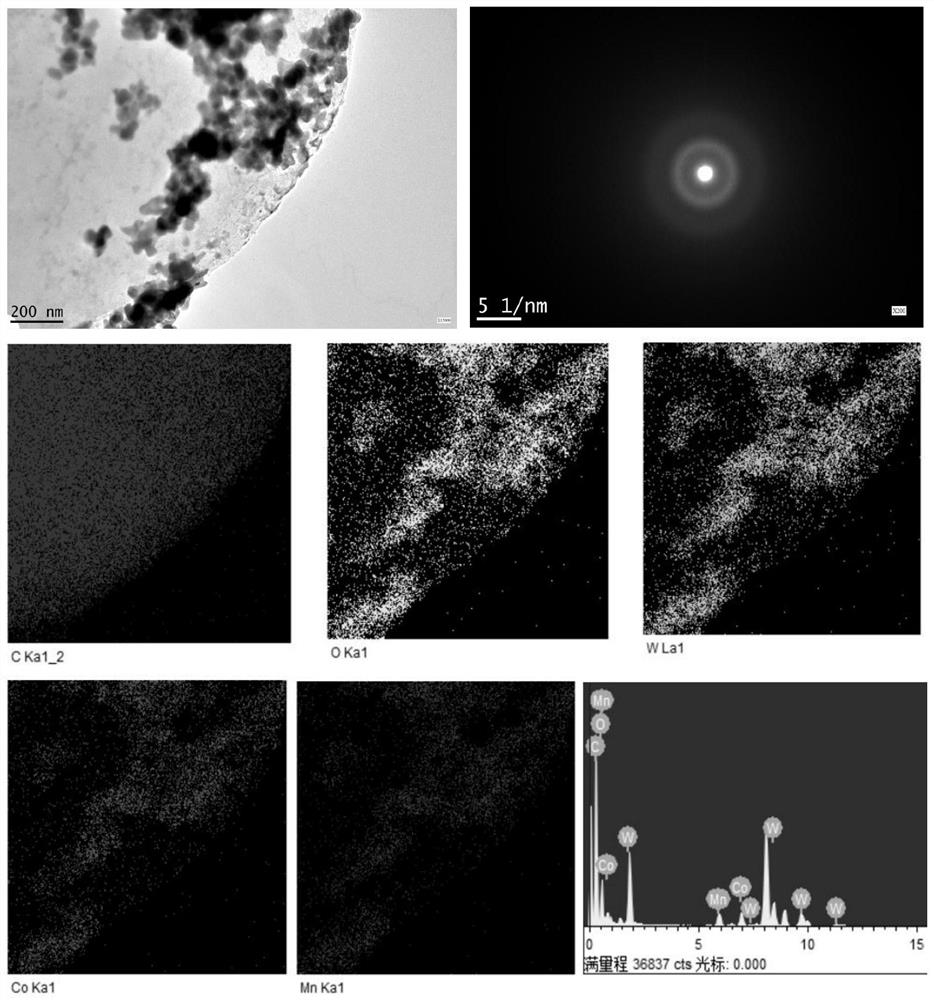

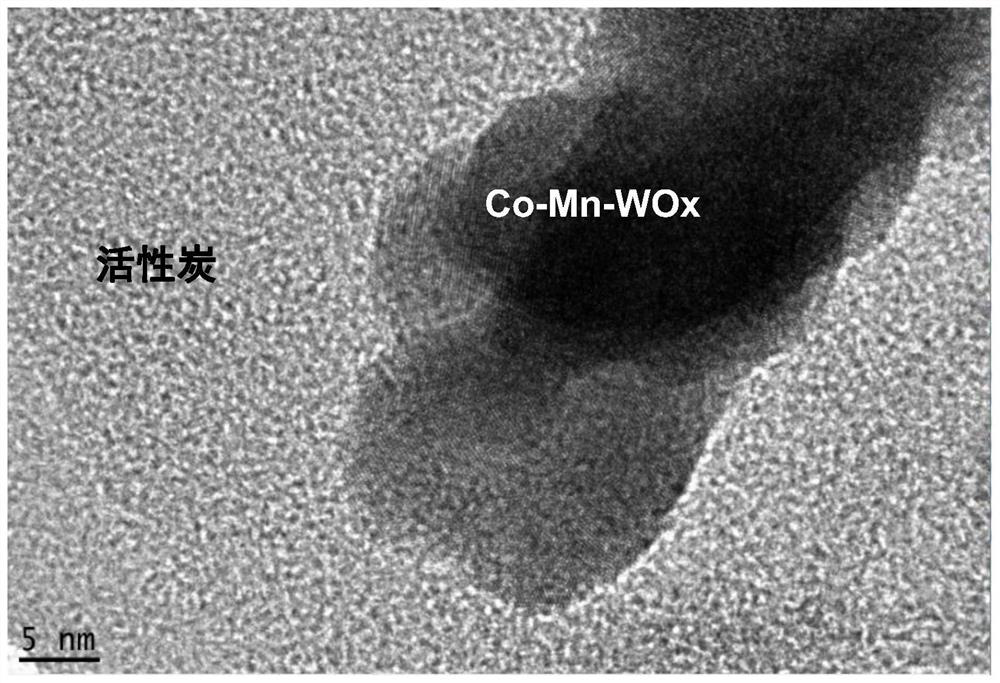

[0035] The amorphous Co x mn y WO 4 The specific preparation process of the activated carbon composite material is as follows: firstly, in 100 mL of water, cobalt chloride and manganese chloride salt are prepared into a solution with a concentration of 2.0 mol / L and 3.0 mol / L respectively; then 0.02 mol of activated carbon is added to fully Ultrasound; Next, add 100 mL of 5.0mol / L sodium tungstate solution quickly (1min) under stirring to form a large amount of flocculent precipitate; finally, quickly (1min) move to a freeze dryer, after 12h of freeze drying , and finally the amorphous Co 0.4 mn 0.6 WO 4 / activated carbon composite.

[0036] The specific surface area of the activated carbon is 1900m 2 / g; pore volume 1.0cm 3 / g; pore size 2.0nm; carbon content 96%; density 0.38g / cc; iodine adsorption value 2100mg / g.

[0037] Add 0.5 g of the above catalyst and 100 mL of ethylbenzene into the reflux device of a three-necked flask, use air as an oxidant, and react at ...

Embodiment 2

[0039] The amorphous Co x mn y WO 4 The specific preparation process of the activated carbon composite material is as follows: first, in 100 mL of water, the cobalt nitrate and manganese nitrate salts are prepared into a solution with a concentration of 3.5 mol / L and 2.0 mol / L respectively; then 0.02 mol of activated carbon is added and fully ultrasonicated; Next, 3.5 mol / L 100mL sodium tungstate solution was quickly added (1min) under stirring to form a large amount of flocculent precipitates; finally, it was quickly (1min) transferred to a freeze dryer, and after 24 hours of freeze drying, the non- Crystalline Co 1 mn 0.57 WO 4 / activated carbon composite.

[0040] The specific surface area of the activated carbon is 1800m 2 / g; pore volume 1.1cm 3 / g; pore size 2.1nm; carbon content 96.5%; density 0.39g / cc; iodine adsorption value 2000mg / g.

[0041] Add 0.8 g of the above catalyst and 100 mL of ethylbenzene into the reflux device of a three-necked flask, use air a...

Embodiment 3

[0043] The amorphous Co x mn y WO 4 The specific preparation process of the activated carbon composite material is as follows: first, in 100 mL of water, the cobalt acetate and manganese acetate salts are prepared into a solution with a concentration of 2.5 mol / L and 1.5 mol / L respectively; then 0.03 mol of activated carbon is added and fully ultrasonicated; Next, 5.0 mol / L 100mL sodium tungstate solution was quickly added (1min) under stirring to form a large amount of flocculent precipitates; finally, it was quickly (1min) transferred to a freeze dryer, and after 24 hours of freeze drying, the non- Crystalline Co 0.5 mn 0.3 WO 4 / activated carbon composite.

[0044] The specific surface area of the activated carbon is 2000m 2 / g; pore volume 1.2cm 3 / g; pore size 2.2nm; carbon content>98%; density 0.40g / cc; iodine adsorption value 2100mg / g.

[0045] Add 1.4 g of the above catalyst and 100 mL of ethylbenzene into the reflux device of a three-necked flask, use air a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com