Preparation method and application of amorphous CoxMnyWO4/activated carbon composite catalytic material

A technology of catalytic materials and composite materials, which is applied in the field of preparation of amorphous CoxMnyWO4/activated carbon composite catalytic materials, can solve the problems of complex preparation process and high cost of raw materials, and achieve high catalytic efficiency and wide industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

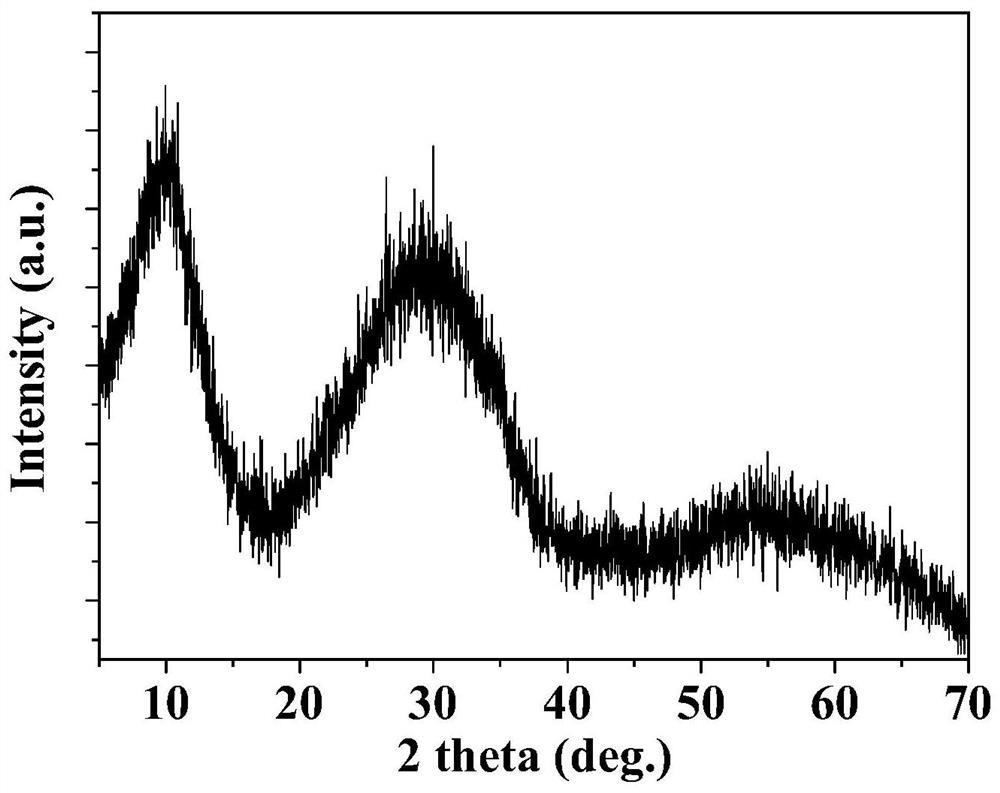

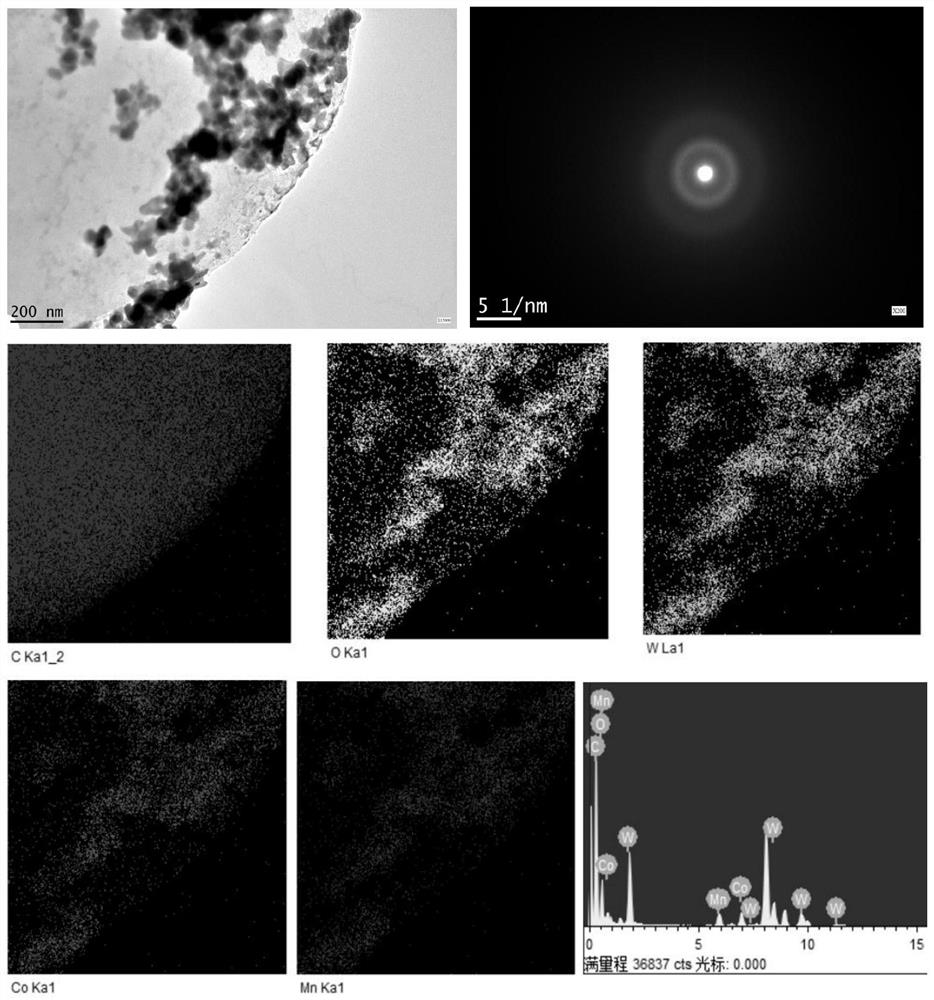

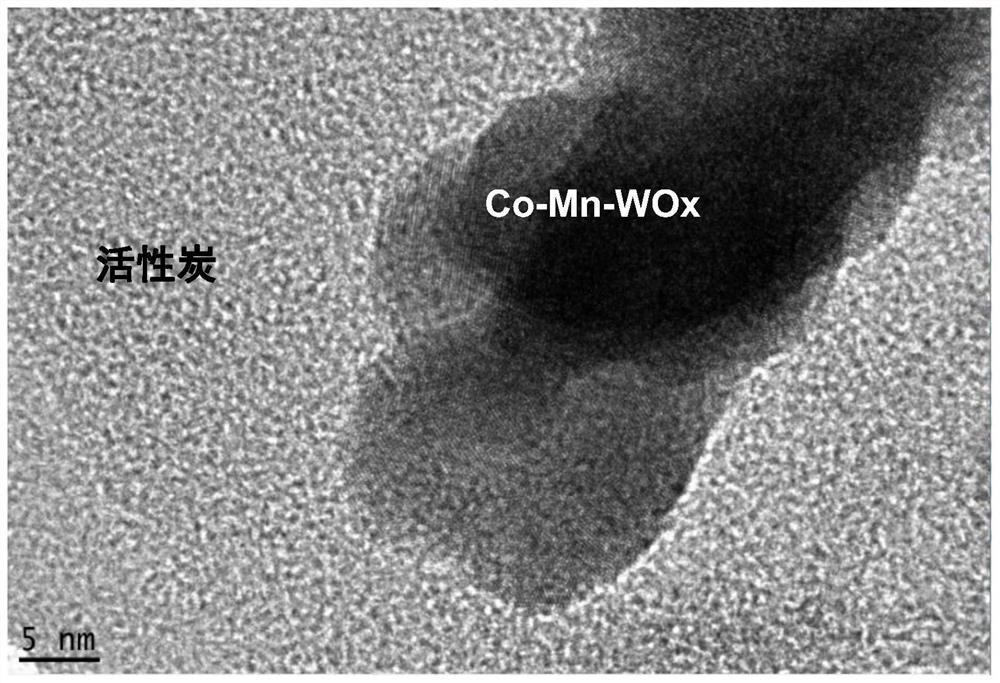

Embodiment 1

[0035] The amorphous Co x mn y WO 4 The specific preparation process of the activated carbon composite material is as follows: firstly, in 100mL water, cobalt chloride and manganese chloride salt are prepared into a solution with a concentration of 2.0mol / L and 3.0mol / L respectively; then 0.02mol activated carbon is added, fully ultrasonicated ; Next, add 100mL of 5.0mol / L sodium tungstate solution quickly (1min) under stirring to form a large number of flocculent precipitates; finally, quickly (1min) move to a freeze dryer, after freeze-drying for 12h, finally Amorphous Co 0.4 mn 0.6 WO 4 / activated carbon composite.

[0036] The specific surface area of the activated carbon is 1900m 2 / g; pore volume 1.0cm 3 / g; pore size 2.0nm; carbon content 96%; density 0.38g / cc; iodine adsorption value 2100mg / g.

[0037] Add 0.5 g of the above catalyst and 100 mL of ethylbenzene into the reflux device of a three-necked flask, use air as an oxidant, and react at 120 °C under no...

Embodiment 2

[0039] The amorphous Co x mn y WO 4 The specific preparation process of the activated carbon composite material is as follows: firstly, in 100mL water, cobalt nitrate and manganese nitrate salt are prepared into a solution, the concentration is 3.5mol / L and 2.0mol / L respectively; then add 0.02mol activated carbon, fully ultrasonic; Next, quickly (1min) add 3.5mol / L 100mL sodium tungstate solution under stirring to form a large number of flocculent precipitates; finally, quickly (1min) move to a freeze dryer, after freeze drying for 24 hours, finally obtain an amorphous State Co 1 mn 0.57 WO 4 / activated carbon composite.

[0040] The specific surface area of the activated carbon is 1800m 2 / g; pore volume 1.1cm 3 / g; pore size 2.1nm; carbon content 96.5%; density 0.39g / cc; iodine adsorption value 2000mg / g.

[0041] Add 0.8 g of the above catalyst and 100 mL of ethylbenzene into the reflux device of a three-necked flask, use air as an oxidant, and react at 130 °C under...

Embodiment 3

[0043] The amorphous Co x mn y WO 4 The specific preparation process of the activated carbon composite material is as follows: first, in 100mL water, the cobalt acetate and manganese acetate salts are prepared into a solution, the concentrations are 2.5mol / L and 1.5mol / L respectively; then 0.03mol activated carbon is added and fully ultrasonicated; then Next, quickly (1min) add 5.0mol / L 100mL sodium tungstate solution under stirring to form a large number of flocculent precipitates; finally, quickly (1min) move to a freeze dryer, after freeze drying for 24 hours, finally obtain an amorphous State Co 0.5 mn 0.3 WO 4 / activated carbon composite.

[0044] The specific surface area of the activated carbon is 2000m 2 / g; pore volume 1.2cm 3 / g; pore size 2.2nm; carbon content>98%; density 0.40g / cc; iodine adsorption value 2100mg / g.

[0045] Add 1.4 g of the above catalyst and 100 mL of ethylbenzene into the reflux device of a three-necked flask, use air as the oxidant, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com