Method for raising plant

一种培育方法、植物的技术,应用在植物学设备和方法、植物生长调节剂、植物生长调节剂等方向,能够解决无法实现增收、过量、上升等问题,达到优异生长促进效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

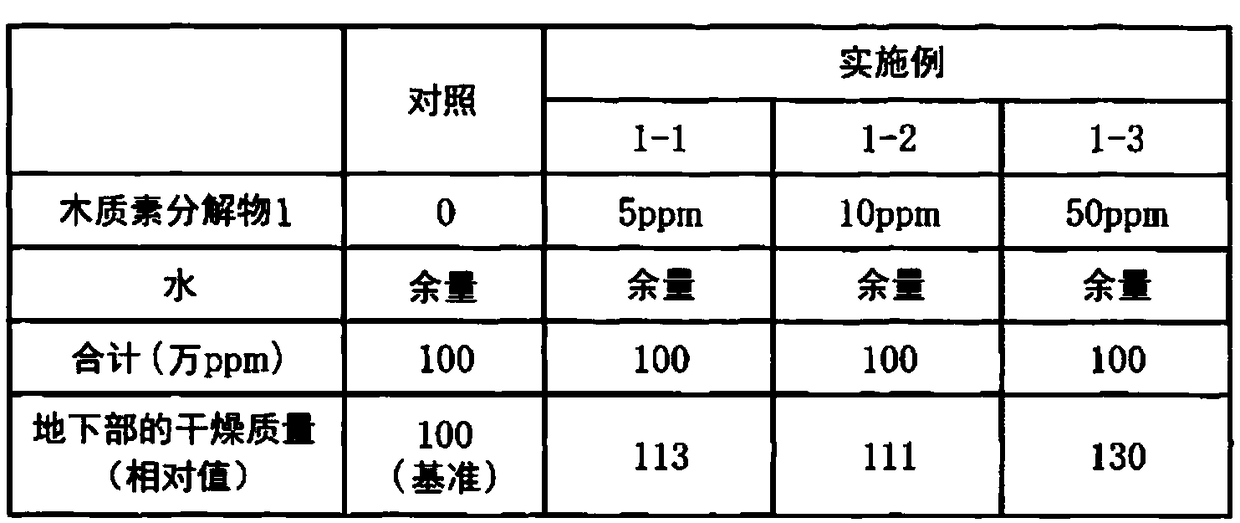

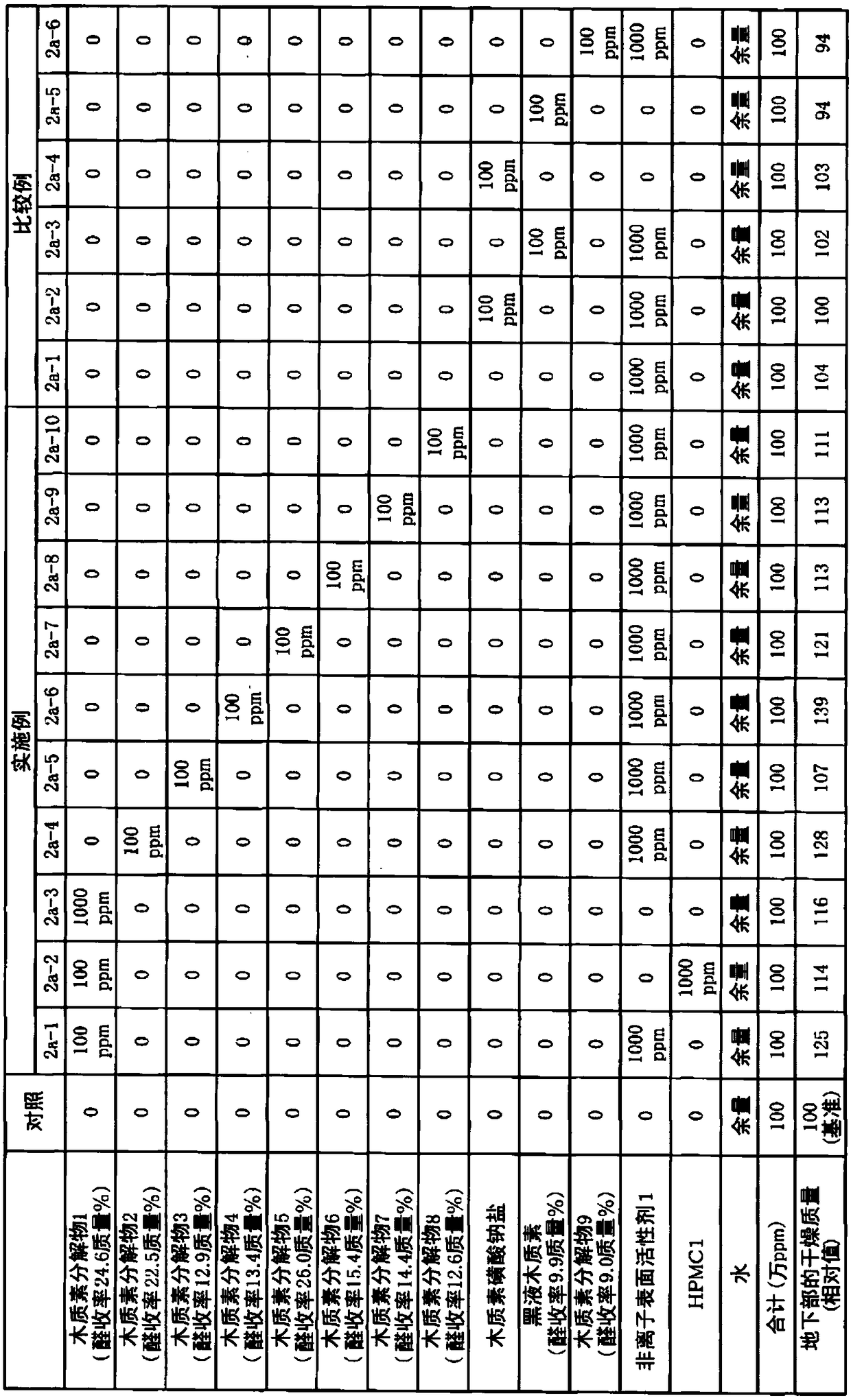

Examples

Embodiment

[0165] 〔Method for measuring aldehyde yield of lignin〕

[0166] 50 mg of lignin decomposition products to be measured, 7 ml of 2M aqueous sodium hydroxide solution, and 0.4 ml of nitrobenzene were put into a 20 ml vial, and heated at 170° C. for 2.5 hours while stirring at 900 rpm. Cool after heating, and extract 3 times with 10 ml of diethyl ether to remove nitrobenzene reduction and excess nitrobenzene. Concentrated hydrochloric acid was added to the remaining aqueous layer to adjust the pH to 1, and further extracted three times with 10 ml of diethyl ether. The diethyl ether extract was distilled off under reduced pressure to obtain an oxidized mixture. The oxidized mixture was distilled to volume with 20 mL of dichloromethane. 2 ml of these were filtered with a Millipore HVHP membrane (manufactured by Millipore Corporation, pore size: 0.45 μm), and supplied to a gas chromatograph (GC).

[0167] As a gas chromatograph, a GC apparatus (manufactured by Agilent Technologies...

manufacture example 1

[0169] Through the following steps 1 and 2a, the lignin decomposition product 1 to be a plant vitalizing agent is produced.

[0170] (Process 1)

[0171] As the herbaceous biomass, 30 g of bagasse by dry mass was put into a glass bottle, and a 1.6% by mass aqueous sodium hydroxide solution was added so that the solid content became 10% by mass. Using an autoclave (TOMY SEIKO Co, Ltd., LSX-700), the glass bottle was heated at 95° C. for 6 hours under normal pressure to obtain a reactant. HF in step 1 was 3.5.

[0172] (Process 2a)

[0173] The reactant obtained in Step 1 was filtered under reduced pressure using a 400-mesh SUS screen and a Buchner funnel. The residue was washed with 300 mL of ion-exchanged water at 90°C. The filtrate and washing liquid were collected, and the pH was adjusted to 4 with 1.0 M hydrochloric acid to obtain a suspension containing lignin decomposition products.

[0174] The suspension obtained in step 2a was centrifuged.

[0175] Centrifugation...

manufacture example 2

[0180] It carried out similarly to manufacture example 1, but the process 2a was changed to the following process 2b, and the lignin decomposition product 2 used as a plant vitality agent was manufactured.

[0181] (Process 2b)

[0182] The reactant obtained in Step 1 was filtered under reduced pressure using a 400-mesh SUS screen and a Buchner funnel. The residue was washed with 300 mL of ion-exchanged water at 90°C. The filtrate and washing solution were collected, and 2.4 L of methanol (Wako Pure Chemical Industries, Ltd., special grade) was added. The precipitate was filtered under reduced pressure (Toyo Filter Paper Co., Ltd., filter paper No. 2), methanol was distilled off from the filtrate under reduced pressure, and the pH was adjusted to 4 with 1.0 M hydrochloric acid to obtain a suspension containing a lignin decomposition product.

[0183] The suspension obtained in step 2b is centrifuged.

[0184] Centrifugation was performed at 10,000 rpm for 20 minutes using "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com