Bagasse saccharifying method

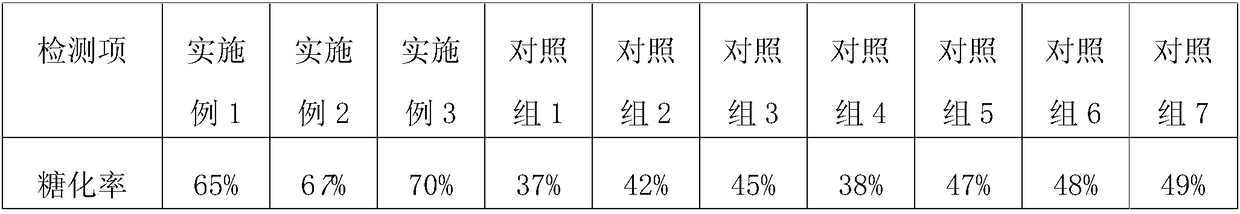

A technology of bagasse and sugarcane, applied in the field of bagasse saccharification, can solve the problems such as difficult to control the end point of fermentation and saccharification, difficult to control saccharification components, etc., achieve high saccharification rate, increase saccharification rate, and good saccharification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for saccharifying sugarcane bagasse, comprising the steps of:

[0022] (1) Bagasse pretreatment: use infrared rays to sterilize the bagasse, and adjust the moisture content of the bagasse to 20% by microwave drying or adding water; the particle size of the bagasse is 0.01mm;

[0023] (2) Saccharification: Add fermentation bacteria to bagasse and place it in 30°C to ferment until ethanol is generated, stop fermentation, use infrared to sterilize bagasse, then add citric acid and dimethylformamide to the sterilized bagasse Sulfoxide 4-butyl ammonium chloride and dimethyl sulfoxide imidazolium salt were degraded at room temperature for 2 days, and the number ratio of the number of viable bacteria in the fermented bacteria was 20:15:10:1 Trichoderma reesei, Aspergillus niger, Aspergillus aculeatus, g Ruver's yeast composition; the added amount of the fermenting bacteria is 1% of the bagasse quality; the added amount of the citric acid is 1% of the bagasse quality, ...

Embodiment 2

[0027] A method for saccharifying sugarcane bagasse, comprising the steps of:

[0028] (1) Bagasse pretreatment: use infrared rays to sterilize the bagasse, and adjust the moisture content of the bagasse to 20% by microwave drying or adding water; the particle size of the bagasse is 0.01mm;

[0029] (2) Saccharification: Add fermentation bacteria to bagasse and place it in 30°C to ferment until ethanol is generated, stop fermentation, use infrared to sterilize bagasse, then add citric acid and dimethylformamide to the sterilized bagasse Sulfoxide 4-butyl ammonium chloride and dimethyl sulfoxide imidazolium salt were degraded at room temperature for 2 days, and the number ratio of the number of viable bacteria in the fermented bacteria was 20:15:10:1 Trichoderma reesei, Aspergillus niger, Aspergillus aculeatus, g Ruver's yeast composition; the added amount of the fermenting bacteria is 1% of the bagasse quality; the added amount of the citric acid is 1% of the bagasse quality, ...

Embodiment 3

[0033] A method for saccharifying sugarcane bagasse, comprising the steps of:

[0034] (1) Bagasse pretreatment: use infrared rays to sterilize the bagasse, and adjust the moisture content of the bagasse to 18% by microwave drying or adding water; the particle size of the bagasse is 20mm;

[0035] (2) Saccharification: Add fermentation bacteria to bagasse and ferment at 28°C until ethanol is produced, stop fermentation, use infrared rays to sterilize bagasse, and then add citric acid and dimethylformamide to the sterilized bagasse Sulfoxide 4-butyl ammonium chloride and dimethyl sulfoxide imidazolium salt were degraded at room temperature for 5 days, and the number ratio of the number of viable bacteria in the fermented bacteria was 20:13:12:1 Trichoderma reesei, Aspergillus niger, Aspergillus aculeatus, gram Ruveria composition; the added amount of the fermenting bacteria is 0.5% of the bagasse quality; the added amount of the citric acid is 3% of the bagasse quality, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com