Pulling wire net and application thereof in cultivation process of vine crops

A crop and wire mesh technology, applied in the field of plant support or scaffolding, can solve the problems of high labor intensity, high cost, waste of resources, etc., and achieve the effect of reducing labor intensity, uniform parameter rules, and avoiding mutual entanglement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

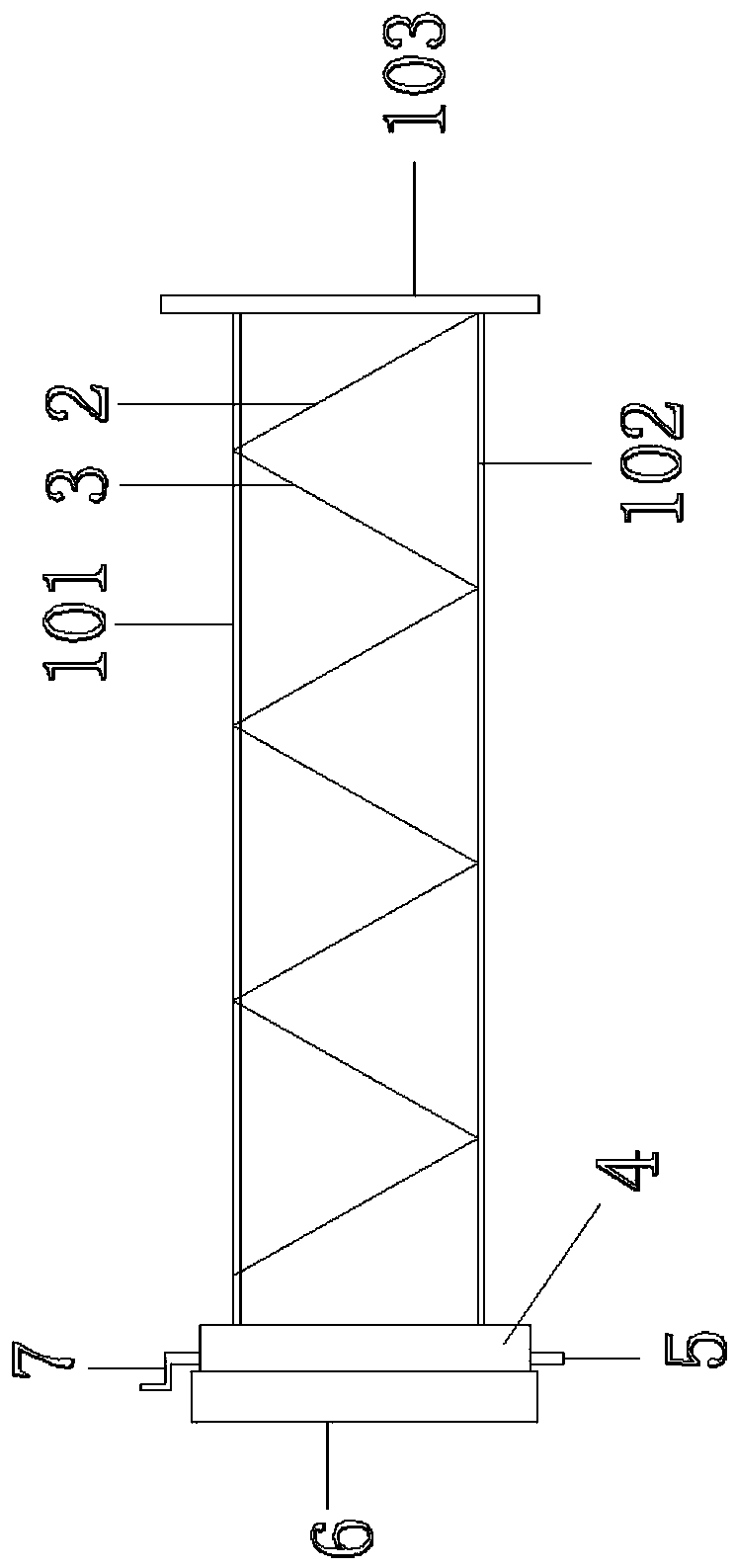

[0036] Such as figure 1 , 2 As shown, a kind of pull wire rolling net described in this embodiment includes a net surface and a winding and unwinding device; the height of the net surface is 1800mm, including upper wefts 101 and lower wefts 102 equidistantly distributed in the height direction, and A vertical bar 103 is provided at any end in the length direction of the mesh surface and has both supporting and winding functions. The vertical bar 103 is connected with the upper weft thread 101 and the lower weft thread 102 .

[0037] It also includes No. 1 meridian 2 and No. 2 meridian 3 which are respectively fixedly connected with the upper latitude 101 and the lower weft 102 and arranged symmetrically in adjacent positions, wherein the angle between the No. 1 meridian 2 and the upper weft 101 is 60°, and The angle between the adjacent No. 2 warp 3 and the upper parallel 101 is 120°.

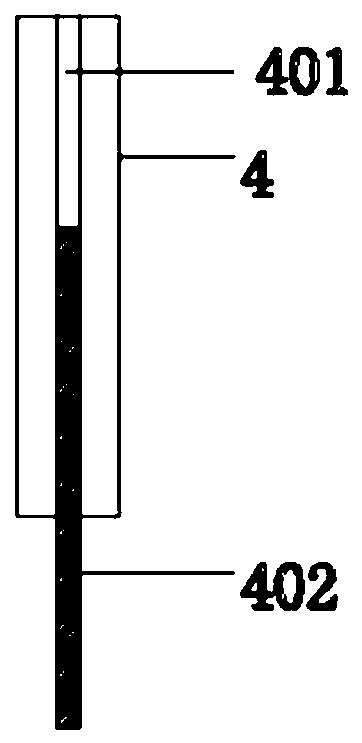

[0038] The rewinding and unwinding device is an inner and outer double-layer structure, i...

Embodiment 2

[0044] Such as figure 1 , 2 As shown, a kind of pull wire rolling net described in this embodiment includes a net surface and a winding and unwinding device; the height of the net surface is 1200mm, including upper wefts 101 and lower wefts 102 equidistantly distributed in the height direction, and A vertical bar 103 is provided at any end in the length direction of the mesh surface and has both supporting and winding functions. The vertical bar 103 is connected with the upper weft thread 101 and the lower weft thread 102 .

[0045] It also includes No. 1 meridian 2 and No. 2 meridian 3 which are respectively fixedly connected with upper latitude 101 and lower weft 102 and arranged symmetrically in adjacent positions, wherein the angle between No. 1 meridian 2 and upper weft 101 is 30°, and The angle between the adjacent No. 2 warp 3 and the upper parallel 101 is 150°.

[0046] The rewinding and unwinding device is an inner and outer double-layer structure, including an inne...

Embodiment 3

[0052] In this embodiment, green beans are planted in a field with an area of 1 mu. The width of the ground is about 33m and the length is about 20m; the guy wire net is used to carry out branch auxiliary traction, and the single width of the ridge for planting green beans is 80cm. The width is 70cm, and a total of 20 planting ridges are set up. The standard unit with a height of 600mm is used for the tension net. In the busy season, a standard unit is set first to ensure that the branches of green beans grow in the correct direction. For the setting of the second standard unit, the final height of the guyed net is 1200mm.

[0053] The guyed net adopts banana rods and leaves to be sorted into strips and then spun into wires, and then compiled into a guyed net for use.

[0054] Since the kidney beans are relatively easy to be eaten by pests, in order to reduce the amount of pesticides used, this embodiment pre-detains the insect repellent on the pull-wire net, that is, soaks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com