Pozzolanic concrete with improvable strength and preparation method thereof

A pozzolan and concrete technology, applied in the field of pozzolan concrete, can solve the problem of not optimal strength, and achieve the effects of good fluidity and self-repairability, high strength performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A pozzolan concrete with improved strength in this embodiment comprises the following raw materials in parts by weight:

[0031] 38 parts of Portland cement, 30 parts of pickled quartz sand, 18 parts of modified pozzolan, 18 parts of melamine-based water reducer, 16 parts of gypsum powder doped with silicon carbide, 6 parts of peridotite, 6 parts of fish eye stone, Mo 6 parts of limestone, 3 parts of porous limestone, 2 parts of marble, 1 part of barium hydroxide, 22 parts of deionized water.

[0032] The preparation method of the acid-washed quartz sand in this embodiment is to soak the quartz sand with 40% dilute sulfuric acid for 1 hour, then wash it with water until neutral, and dry it at 110° C. for 2 hours to obtain the acid-washed quartz sand.

[0033] The preparation method of the modified volcanic ash in this embodiment is to add the volcanic ash to water for dispersion, then add dilute sulfuric acid with a mass fraction of 20% to it, then neutralize it to neut...

Embodiment 2

[0044] A pozzolan concrete with improved strength in this embodiment comprises the following raw materials in parts by weight:

[0045] 44 parts of Portland cement, 34 parts of pickled quartz sand, 24 parts of modified pozzolan, 22 parts of melamine-based water reducer, 20 parts of gypsum powder doped with silicon carbide, 10 parts of peridotite, 10 parts of fish eye stone, Mo 10 parts of stone, 5 parts of porous limestone, 4 parts of marble, 3 parts of barium hydroxide, 28 parts of deionized water.

[0046] The preparation method of the acid-washed quartz sand in this embodiment is to soak the quartz sand with 50% dilute sulfuric acid for 1 hour, then wash it with water until neutral, and dry it at 130° C. for 4 hours to obtain acid-washed quartz sand.

[0047] The preparation method of the modified volcanic ash in this embodiment is to add volcanic ash to water for dispersion, then add dilute sulfuric acid with a mass fraction of 30% to it, then neutralize it to neutrality w...

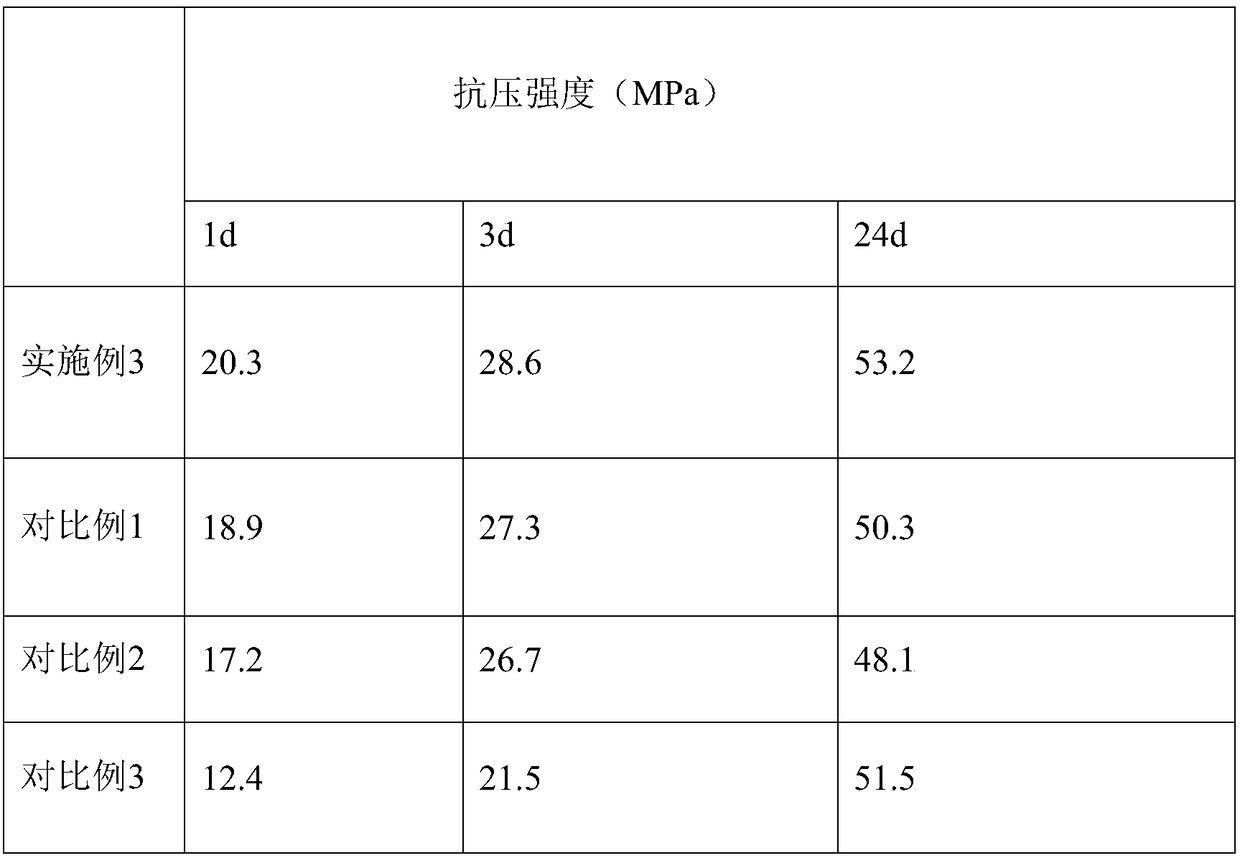

Embodiment 3

[0058] A pozzolan concrete with improved strength in this embodiment comprises the following raw materials in parts by weight:

[0059] 41 parts of Portland cement, 32 parts of pickled quartz sand, 21 parts of modified pozzolan, 20 parts of melamine-based water reducer, 18 parts of gypsum powder doped with silicon carbide, 8 parts of peridotite, 8 parts of fish eye stone, Mo 8 parts of stone, 4 parts of porous limestone, 3 parts of marble, 2 parts of barium hydroxide, 25 parts of deionized water.

[0060] The preparation method of the acid-washed quartz sand in this embodiment is to soak the quartz sand with 45% dilute sulfuric acid for 1 hour, then wash it with water until neutral, and dry it at 120° C. for 3 hours to obtain the acid-washed quartz sand.

[0061] The preparation method of the modified volcanic ash in this embodiment is to add volcanic ash to water for dispersion, then add dilute sulfuric acid with a mass fraction of 25% to it, then neutralize it to neutrality ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com