Modified silica gel product and preparation method thereof

A technology of silica gel and products, which is applied in the field of modified silica gel products and its preparation, which can solve the problems of affecting the absorption of water and nutrients and the discharge of metabolic waste, unfavorable skin surface metabolism, and accelerated volatilization of water and nutrients, so as to promote the microcirculation of the human body, increase the Human microcirculation, the effect of being easy to popularize and apply on a large scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

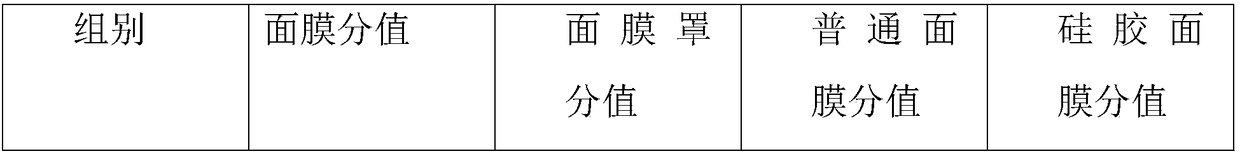

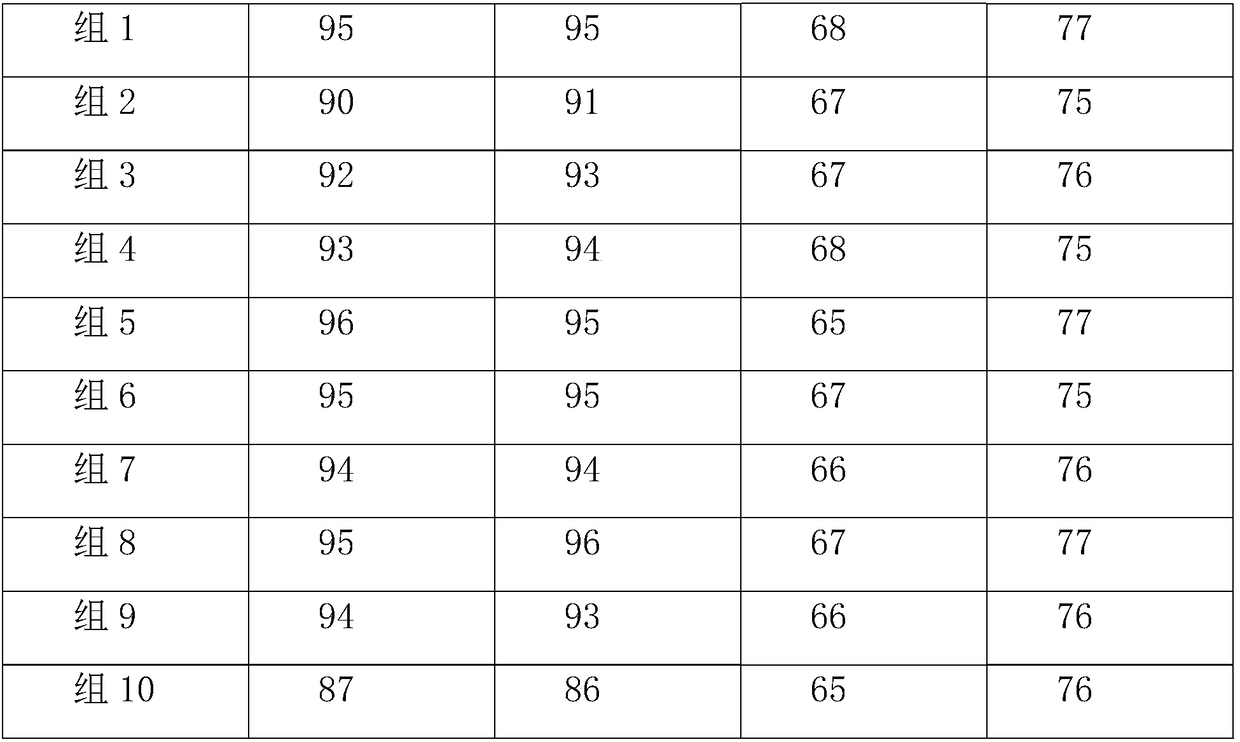

Examples

Embodiment 1

[0051] Get the following components: by weight, 60 parts of food grade silica gel, 40 parts of white carbon black prepared by precipitation method, 3 parts of biomass graphene (0.5 parts of particle diameter D100=0.5 μm, 2.5 parts of particle diameter 1-5 μm) , 2 parts of methyl silicone oil, 1 part of 2,4-dichlorobenzoyl peroxide;

[0052] Mix the components in the following manner:

[0053] Group 1: the components are mixed directly;

[0054] Group 2: (a), mixing biomass graphene with particle size D100=0.5 μm with silica gel powder, then adding bridging agent, white carbon black and silicone oil, and mixing to obtain the first mixture;

[0055] (b) Add biomass graphene with a particle size of 1-5 μm into the first mixture and mix well.

[0056] Group 3: (a), mixing biomass graphene with particle size D100=0.5 μm and white carbon black, then adding bridging agent, silica gel and silicone oil, and mixing to obtain the first mixture;

[0057] (b) Add biomass graphene with a...

Embodiment 2

[0078] A modified silica gel product, prepared by the following steps:

[0079] Take the following components: by weight, 50 parts of food-grade silica gel, 30 parts of white carbon black prepared by precipitation method, reduced graphene oxide (0.05 parts of particle size D100=0.8 μm, 0.05 parts of particle size 1-6 μm) 0.1 Parts, 0.5 parts of vinyl silicone oil, 0.2 parts of di-tert-butyl peroxide;

[0080] (a), the reduced graphene oxide with a particle diameter of D100=0.8 μm is mixed with white carbon black in batches, and then the bridging agent di-tert-butyl peroxide, silica gel and vinyl silicone oil are added in batches, and each mixing , the component containing the graphene material is 9 times of the mass of the graphene material component, and the first mixture is obtained after mixing;

[0081] (b), adding reduced graphene oxide with a particle size of 1-6 μm into the first mixture, and mixing;

[0082] (c) Put the obtained mixture into a mold and vulcanize to p...

Embodiment 3

[0084] A modified silica gel product, prepared by the following steps:

[0085] Take the following components: by weight, 55 parts of food grade silica gel, 35 parts of white carbon black prepared by precipitation method, 0.5 parts of graphene oxide (0.1 part of particle size D100=0.3 μm, 0.4 part of particle size of 1-8 μm) , 1 part of ethyl hydrogen-containing silicone oil, 0.5 part of ethyl orthosilicate;

[0086] (a), the graphene oxide of particle diameter D100=0.3 μm is mixed with white carbon black in batches, then adds orthosilicate ethyl ester, silica gel and ethyl hydrogen-containing silicone oil in batches, when mixing each time, containing The component of the graphene material is 8 times of the mass of the component not containing the graphene material, and the first mixture is obtained after mixing;

[0087] (b), adding graphene oxide with a particle size of 1-8 μm into the first mixture, and mixing;

[0088] (c) Put the obtained mixture into a mold and vulcani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com