Preparation method for synthesis of silica-coated inorganic perovskite quantum dots

A technology for synthesizing silicon dioxide and silicon dioxide, which is applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of limited application and great influence of material properties, and achieves short preparation time, high luminous efficiency, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

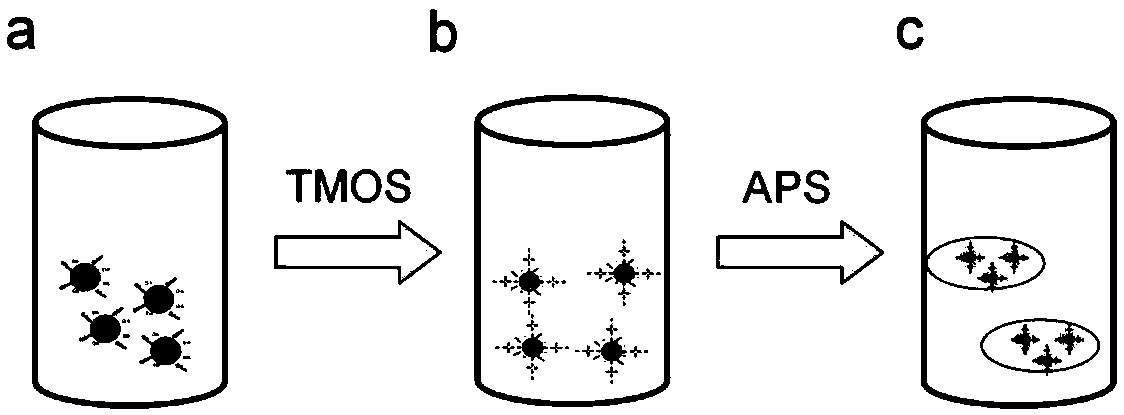

[0039] Embodiment 1: A kind of silica coated inorganic CsPbBr 3 The preparation method of quantum dots, its preparation process sees attached figure 1 ,Proceed as follows:

[0040] 1) Silanization treatment of quantum dots:

[0041] 1nmol CsPbBr 3 Dispersion of quantum dots In 2ml of n-hexane, add 8μl of tetramethoxysilane, stir for 24 hours, the reaction temperature is 25°C, and react in a sealed environment to obtain silica-modified CsPbBr 3 A solution of quantum dots. Other types of quantum dots (CsPbCl 3 , CsPbI 3 ,CsSnBr 3 , CsSnCl 3 , CsSnI 3 Quantum dots) silanization treatment, all using tetramethoxysilane.

[0042] 2), preparation of silica-coated perovskite quantum dots:

[0043] In silanized CsPbBr 3 Add 0.2 μl of 3-aminopropyltrimethoxysilane to the quantum dot solution, and stir the mixed solution for 1 hour in a sealed state. Quantum dots appear to agglomerate. After centrifugal precipitation and ethanol cleaning, the precipitate is dispersed in ethano...

Embodiment 2

[0044] Example 2: Silica-coated inorganic CsPbBr 3-x Cl x The preparation method of quantum dots, the steps are as follows:

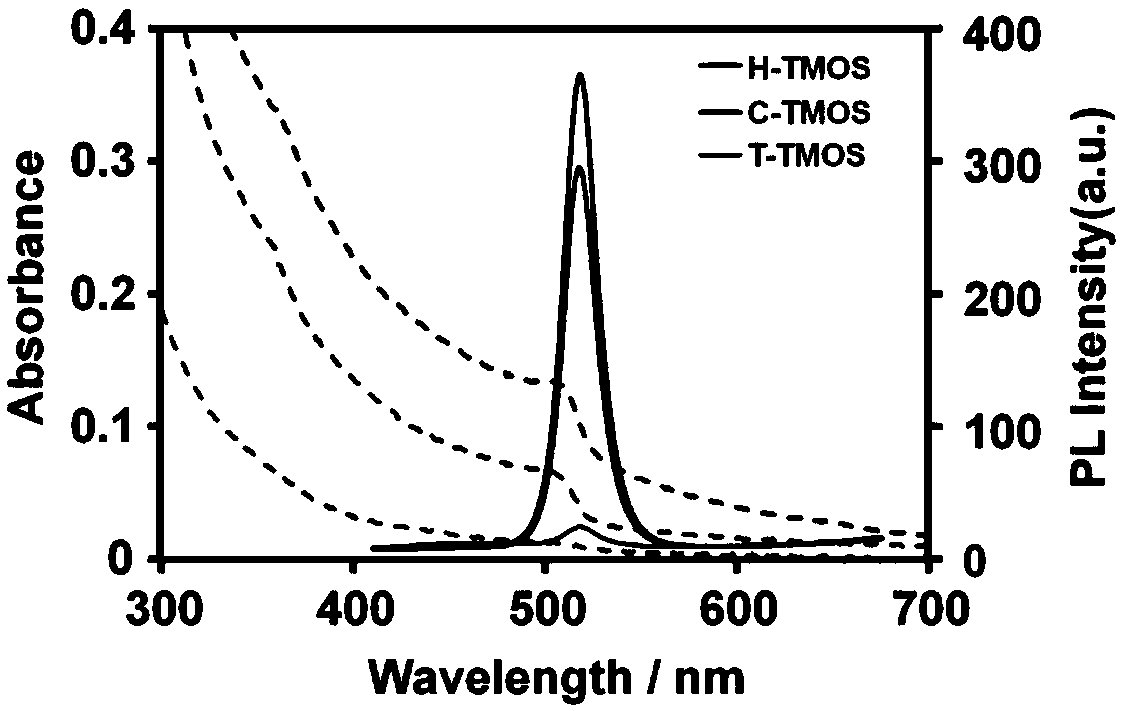

[0045] Similar to Example 1, 1nmol CsPbBr 3-x Cl x Quantum dots were dispersed in 2ml of n-hexane, 5μl of tetramethoxysilane was added, stirred for 24 hours, the reaction temperature was 25°C, and reacted in a sealed environment to obtain silica-modified CsPbBr 3-x Cl x A solution of quantum dots. Then add 0.2 μl of 3-aminopropyltrimethoxysilane, and in a sealed state, stir the mixed solution for 1 hour, the quantum dots appear to agglomerate, after centrifugal precipitation and ethanol cleaning, the precipitate is dispersed in ethanol to obtain silica Coated CsPbBr 3 quantum dots. Silica-coated CsPbBr 3 The absorption fluorescence spectrum of quantum dots is attached Image 6 shown.

Embodiment 3

[0046] Example 3: Silica-coated inorganic CsPbBr 3-x I x The preparation method of quantum dots, the steps are as follows

[0047] Similar to Example 1, 1nmol CsPbBr 3-x I x Quantum dots were dispersed in 2ml of n-hexane, 8μl of tetramethoxysilane was added, stirred for 24 hours, the reaction temperature was 25°C, and reacted in a sealed environment to obtain silica-modified CsPbBr 3- x I x A solution of quantum dots. Then add 0.2 μl of 3-aminopropyltrimethoxysilane, and in a sealed state, stir the mixed solution for 1 hour, the quantum dots appear to agglomerate, after centrifugal precipitation and ethanol cleaning, the precipitate is dispersed in ethanol to obtain silica Coated CsPbBr 3 quantum dots. Silica-coated CsPbBr 3 The absorption fluorescence spectrum of quantum dots is attached Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com