An anaerobic fermentation treatment system and method for simultaneous deamination of ultra-high temperature biological hydrolysis

A technology of anaerobic fermentation and biohydrolysis, which is applied in the fields of biomass pretreatment, biochemical equipment and methods, fermentation, etc., can solve the problems of weak methane production capacity, low anaerobic digestion performance, and low anaerobic fermentation efficiency, etc. Effects of improved gas production capacity, improved methane production potential, and improved waste disposal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

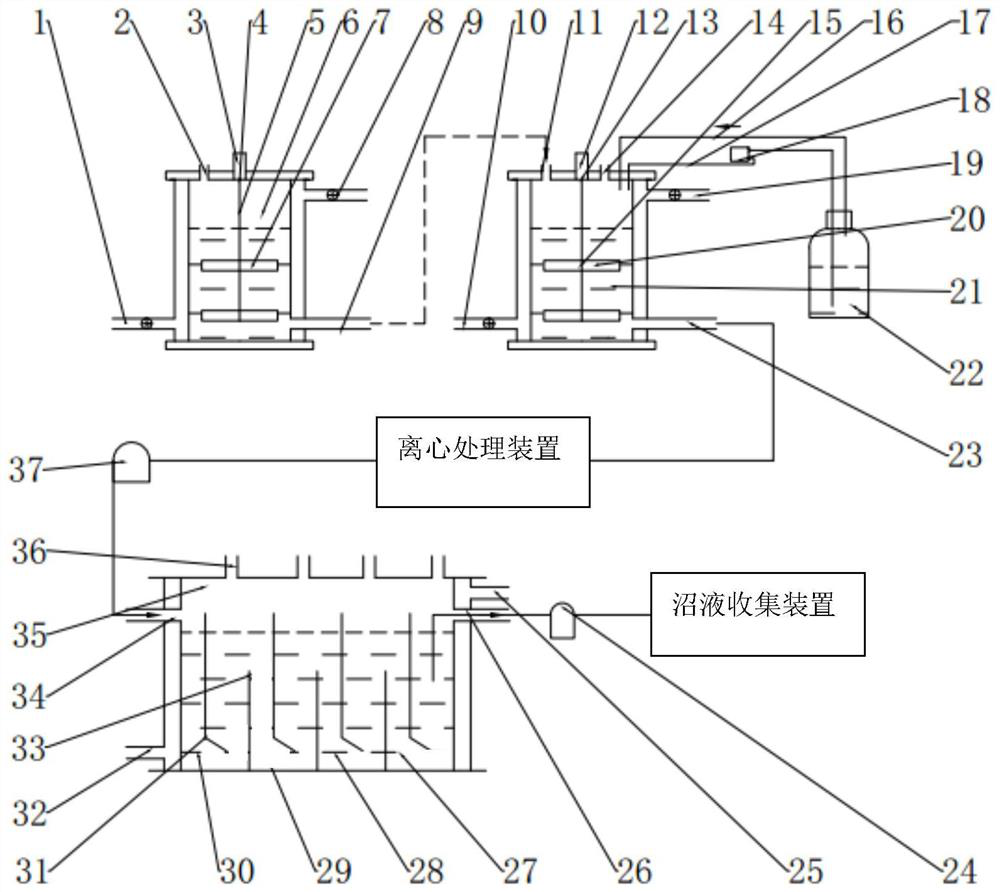

[0096]Ultra-high temperature biological hydrolysis of chicken manure and simultaneous removal of ammonia. The effective volume of the hydrolysis tank 21 is 10L, and the effective volume of the acid absorption tank 22 is 0.5L.

[0097]Before the anaerobic fermentation is performed, the first gas collection port 14 and the second gas collection port 36 are respectively connected to the gas collection bag.

[0098]a) Ultra-high temperature biohydrolysis.

[0099]The initial TS (total solid content) of the chicken manure raw material is 10-15%.

[0100]The TS (total solid content) of the chicken manure raw material in the hydrolysis tank 21 is 10-20%.

[0101]During the hydrolysis process, the hydraulic residence time of the chicken manure raw materials in the hydrolysis tank 21 is 5 days.

[0102]The temperature of the circulating water injected into the water bath interlayer of the raw material tank 6 is 4°C.

[0103]The temperature of the water injected into the water bath interlayer of the hydrolysis ta...

Embodiment 2

[0116]Ultra-high temperature biological hydrolysis of pig manure and simultaneous removal of ammonia. The effective volume of the hydrolysis tank 21 is 10L, and the effective volume of the acid absorption tank 22 is 0.5L.

[0117]Before the anaerobic fermentation is performed, the first gas collection port 14 and the second gas collection port 36 are respectively connected to the gas collection bag.

[0118]a) Ultra-high temperature biohydrolysis.

[0119]The initial TS (total solid content) of the pig manure raw material is 10-15%.

[0120]The TS (total solid content) of the pig manure raw material in the hydrolysis tank 21 is 10-20%.

[0121]During the hydrolysis process, the hydraulic residence time of the raw material of pig manure in the hydrolysis tank 21 is 3 days.

[0122]The temperature of the circulating water injected into the water bath interlayer of the raw material tank 6 is 4°C.

[0123]The temperature of the water injected into the water bath interlayer of the hydrolysis tank 21 is 70°C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com