Infrared transparent window with electromagnetic shielding function and preparation method of infrared transparent window

A technology for electromagnetic shielding and transparent windows, which is applied in the field of infrared transparent windows and its preparation, can solve problems such as the difficulty of achieving high infrared transmittance and high electromagnetic shielding efficiency at the same time, so as to improve electromagnetic shielding efficiency, improve the ability to resist electromagnetic interference, The effect of improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

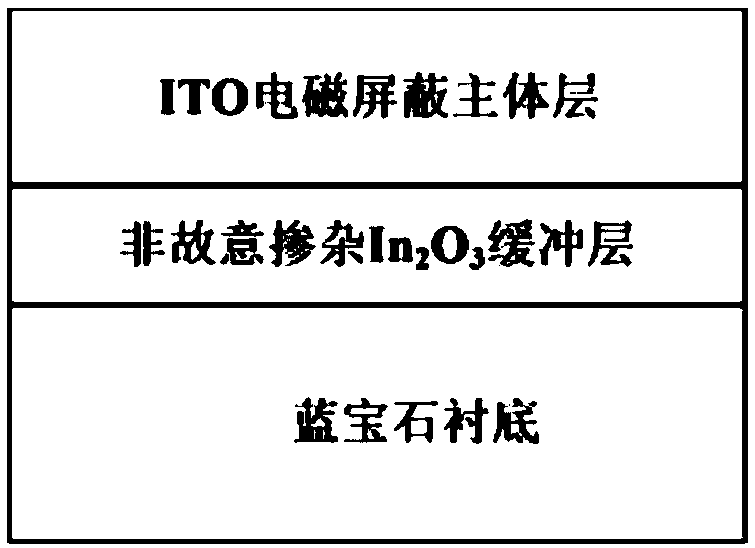

[0040] An infrared window containing a high mobility electromagnetic shielding layer.

[0041] Step 1: Select a clean sapphire substrate with a 0.2° deviation angle between the surface and the c crystal plane, double-sided polishing, and a thickness of 430 μm.

[0042] Step 2: Send the substrate into the reaction chamber of the MOCVD equipment, and let the tray rotate at a speed of 750 rpm;

[0043] Step 3: The temperature of the reaction chamber is raised to 630° C.; at the same time, 10 slm of argon gas is introduced into the reaction chamber, and the pressure of the reaction chamber is controlled at 9 Torr through the pressure control system.

[0044] Step 4: Immerse the bubbling bottle containing trimethylindium and tetrakis(dimethylamino)tin in two constant temperature water tanks, control the temperature of the bubbling bottle to 25°C and 5°C through the constant temperature water tank, and pass the mass flow meter And pressure gauge, control the pressure of two bubblin...

Embodiment 2

[0054] An infrared window comprising an electromagnetic shielding main body layer with non-uniform distribution of doping concentration.

[0055] Step 1: Select a clean sapphire substrate with a 0.2° deviation angle between the surface and the c crystal plane, double-sided polishing, and a thickness of 430 μm.

[0056] Step 2: Send the substrate into the reaction chamber of the MOCVD equipment, and let the tray rotate at a speed of 750 rpm;

[0057] Step 3: The temperature of the reaction chamber is raised to 630° C.; at the same time, 10 slm of argon gas is introduced into the reaction chamber, and the pressure of the reaction chamber is controlled at 9 Torr through the pressure control system.

[0058] Step 4: Immerse the bubbling bottle containing trimethylindium and tetrakis(dimethylamino)tin in two constant temperature water tanks, control the temperature of the bubbling bottle to 25°C and 5°C through the constant temperature water tank, and pass the mass flow meter And ...

Embodiment 3

[0067] An infrared window containing a high mobility electromagnetic shielding layer.

[0068] Step 1: Select a clean sapphire substrate with a 2° deviation angle between the surface and the c crystal plane, a thickness of 100 μm, and double-sided polishing.

[0069] Step 2: Send the substrate into the reaction chamber of the MOCVD equipment, and let the tray rotate at a speed of 750 rpm;

[0070] Step 3: The temperature of the reaction chamber is raised to 900° C.; at the same time, 10 slm of argon gas is introduced into the reaction chamber, and the pressure of the reaction chamber is controlled at 760 Torr through the pressure control system.

[0071] Step 4: Immerse the bubbling bottle containing trimethylindium and tetrakis(dimethylamino)tin in two constant temperature water tanks, control the temperature of the bubbling bottle to 25°C and 5°C through the constant temperature water tank, and pass the mass flow meter And pressure gauge, control the pressure of two bubblin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com