Method for monitoring horizontal well staged fracturing effects by micro-element tracer

A trace element, staged fracturing technology, which is applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve problems such as inaccurate evaluation of fracturing effects, avoid inaccurate monitoring results and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The method of using trace element tracers to monitor the effect of staged fracturing of a horizontal well is designed for 4 stages of fracturing for one horizontal well.

[0057] Specific steps are as follows:

[0058] (1) The number of stages for fracturing monitoring in horizontal wells is 4, and trace elements with low background concentrations in each well section are selected as tracers, and the tracers injected in the first to third stages are ethylenediaminetetramethylene Yttrium phosphonate, samarium ethylenediaminetetramethylenephosphonate, gadolinium ethylenediaminetetramethylenephosphonate, thulium ethylenediaminetetramethylenephosphonate;

[0059] (2) According to the on-site fracturing construction parameters: the total injection volume of single-stage pre-fluid and sand-carrying fluid is 300m 3 , construction displacement 5m 3 / min, the amount of tracer in each section is 150g;

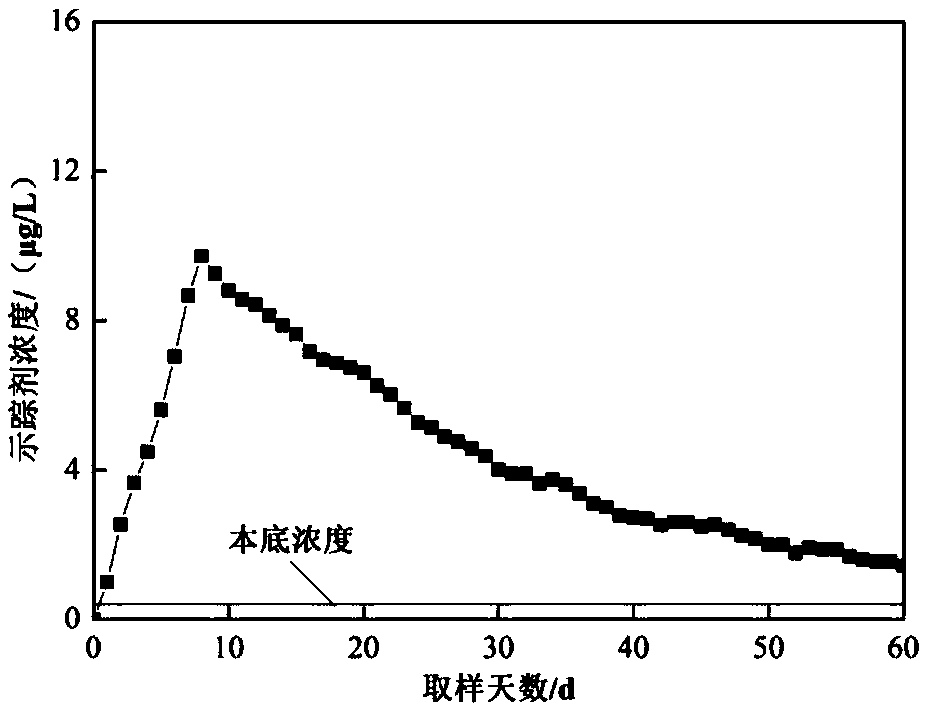

[0060] (3) When fracturing starts, use a constant flow pump to add tracer ...

Embodiment 2

[0068] The method of using trace element tracers to monitor the effect of staged fracturing of a horizontal well aims at designing 9 stages of fracturing for one horizontal well.

[0069] Specific steps are as follows:

[0070] (1) The number of stages for horizontal well fracturing monitoring is 9, and trace elements with low background concentrations in each well section are selected as tracers. The tracers injected from the first to ninth stages are yttrium chloride and chlorine Samarium Hydroxylamine, Gadolinium Hydroxylamine Chloride, Erbium Hydroxylamine Chloride, Neodymium Hydroxylamine Chloride, Praseodymium Hydroxylamine Chloride, Ytterbium Hydroxylamine Chloride, Holmium Hydroxylamine Chloride, Europium Hydroxylamine Chloride;

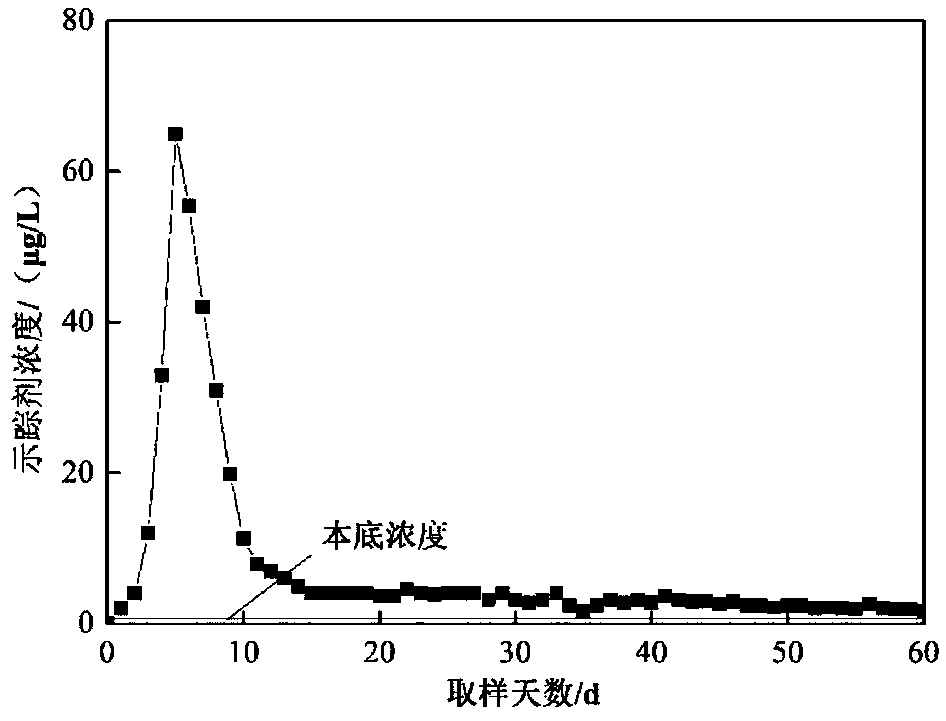

[0071] (2) According to the on-site fracturing construction parameters (the total injection volume of pre-fluid and sand-carrying fluid in a single stage is 500m 3 , construction displacement 5m 3 / min), the consumption of each section trac...

Embodiment 3

[0077] The method of using trace element tracers to monitor the effect of staged fracturing of horizontal wells is designed for 10 stages of fracturing for one horizontal well.

[0078] Specific steps are as follows:

[0079] (1) The number of stages for fracturing monitoring in horizontal wells is 10, and trace elements with low background concentrations in each well section are selected as tracers, and the tracers injected in the first to tenth stages are yttrium ethylenediaminetetraacetate , Samarium EDTA, Gadolinium EDTA, Erbium EDTA, Neodymium EDTA, Praseodymium EDTA, Ytterbium EDTA, Holmium EDTA, Europium EDTA, Thulium EDTA;

[0080] (2) According to the on-site fracturing construction parameters (the total injection volume of pre-fluid and sand-carrying fluid in a single stage is 400m 3 , construction displacement 5m 3 / min), the consumption of each section tracer is 200g;

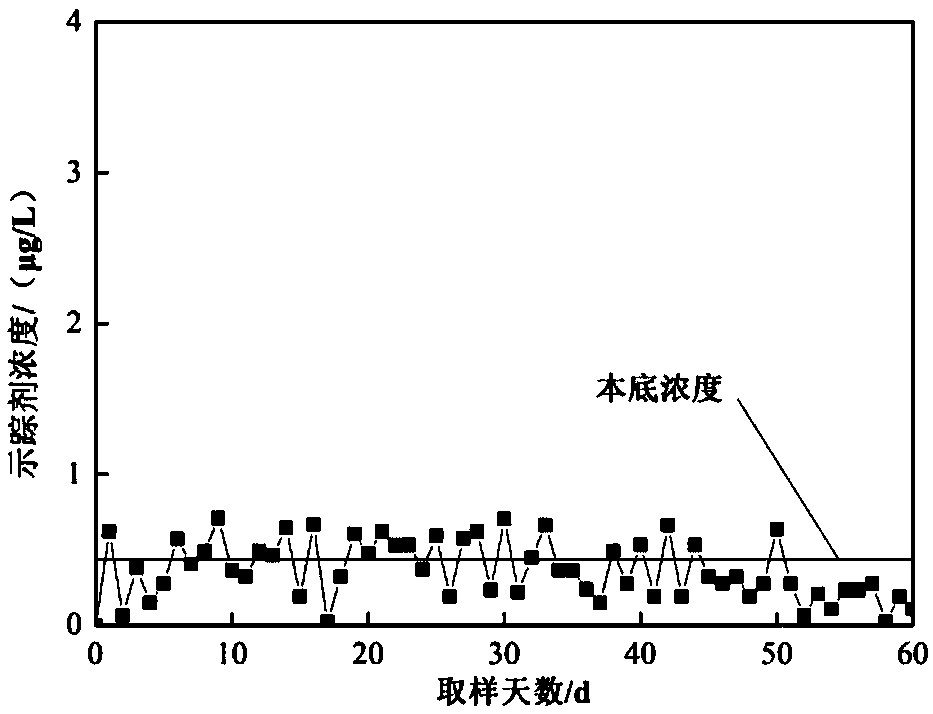

[0081] (3) When fracturing starts, use a constant flow pump to add tracer to the sand mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com