Multi-motor optimization control system and optimization control method thereof

An optimized control and multi-motor technology, applied in the control system, motor speed or torque control, pump control, etc., can solve the problems of reduced inlet pressure, impact on economic benefits, increased energy consumption of water pumps, etc., to achieve simple operation, Control flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a further understanding and understanding of the structural features and the achieved effects of the present invention, preferred embodiments and accompanying drawings are used to describe in detail, as follows:

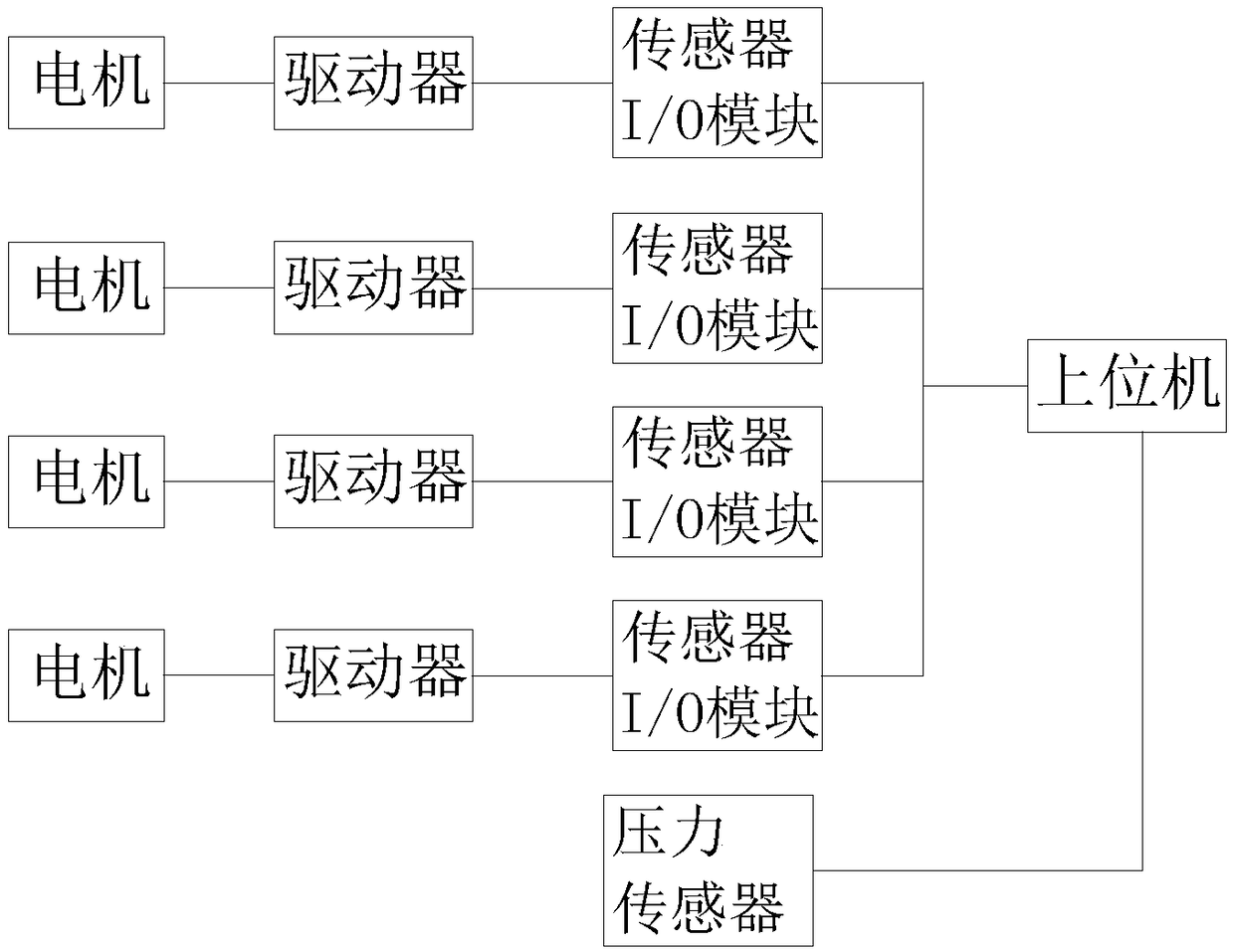

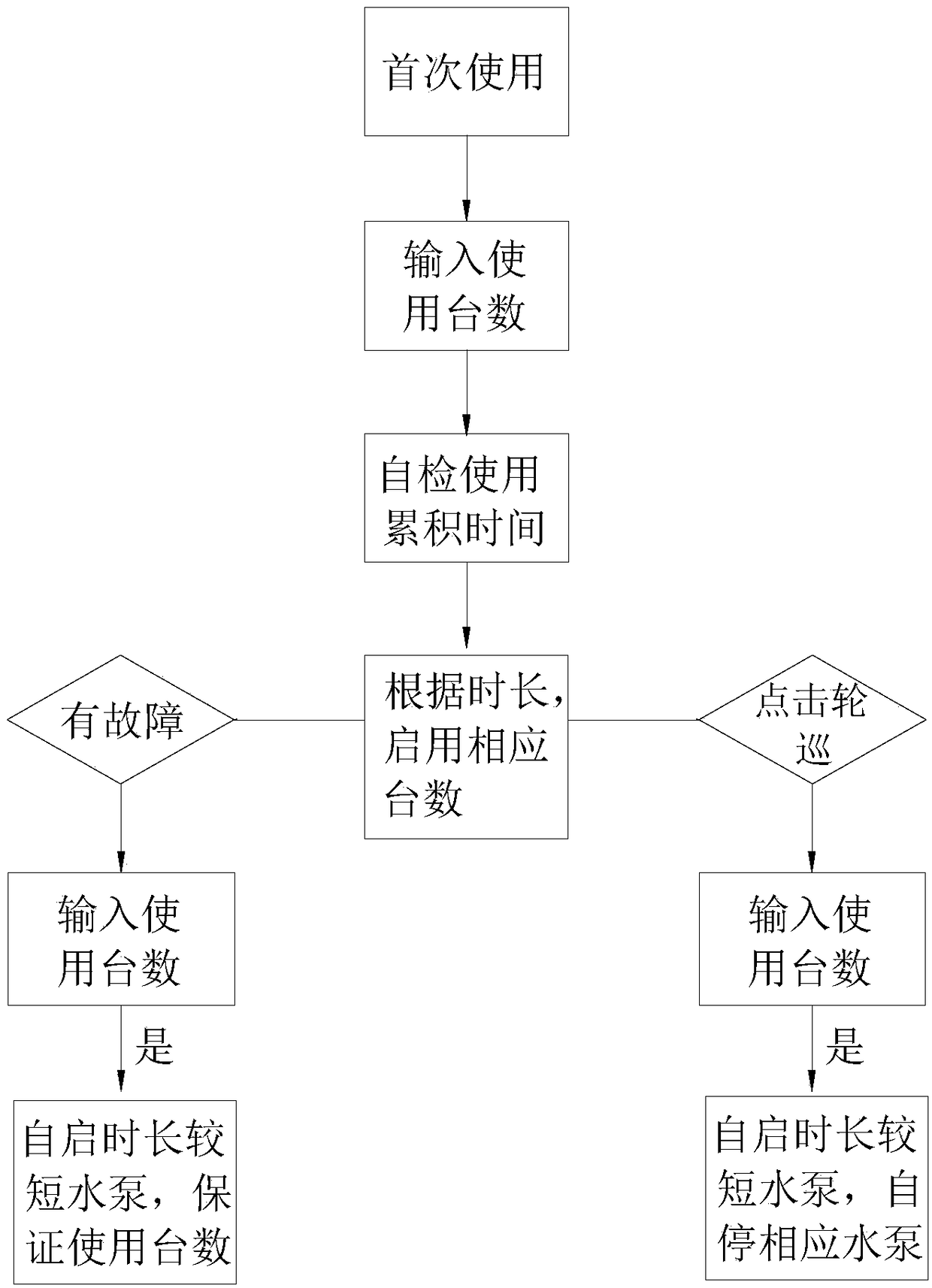

[0029] A multi-motor optimal control system, such as figure 1 As shown, the optimized control system includes multiple motors, taking four as an example, the motors are water pump motors. Each motor is connected to the sensor I / O module and the driver, and all the drivers and sensor I / O modules are connected to the upper computer; the upper computer is provided with a one-key tour button. The upper computer is connected with the pressure sensor of the air compressor.

[0030] As a further preferred technical solution, the sensor I / O module includes a DO module that controls the start and stop of the motor, an AO module that controls the actual speed of the motor, a DI module that monitors the running state of the motor, and an AI module that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com