Carbon nanotube thin film transistor with photoresist as gate insulating layer and its fabrication and application

A carbon nanotube film, gate insulating layer technology, applied in transistors, nanotechnology for information processing, nanotechnology, etc., can solve the problems of limitations, cumbersome preparation process of gate insulating layer, etc., and achieve low operating voltage and power consumption , the effect of protecting electrical performance and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

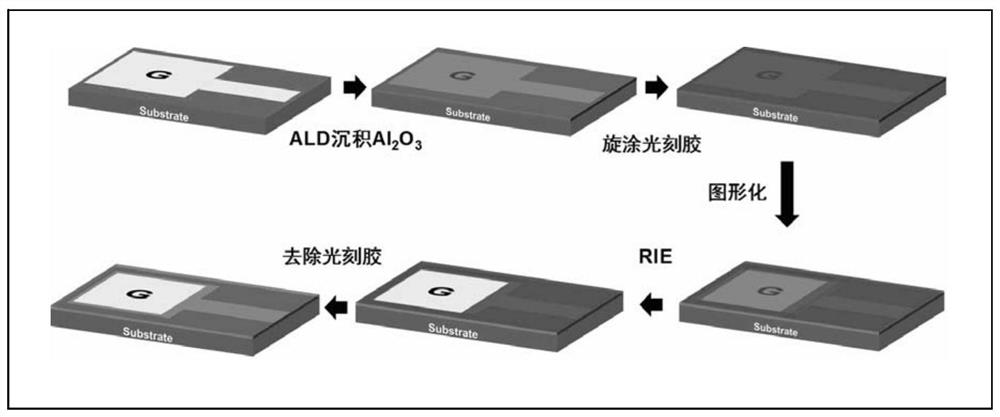

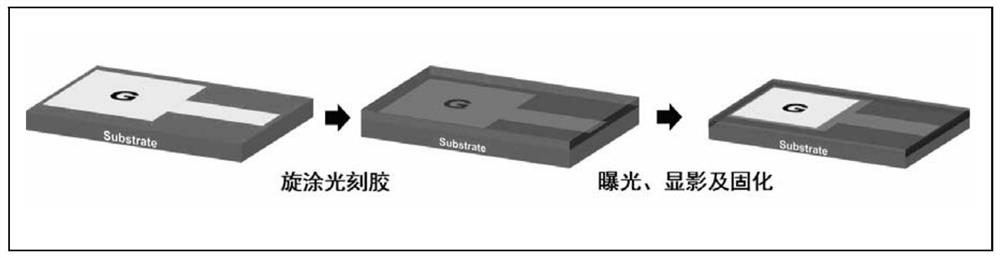

[0044] In this embodiment, the carbon nanotube thin film transistor and storage device using photoresist as the gate insulating layer are fabricated as follows:

[0045] 1. Optimization of photoresist curing conditions

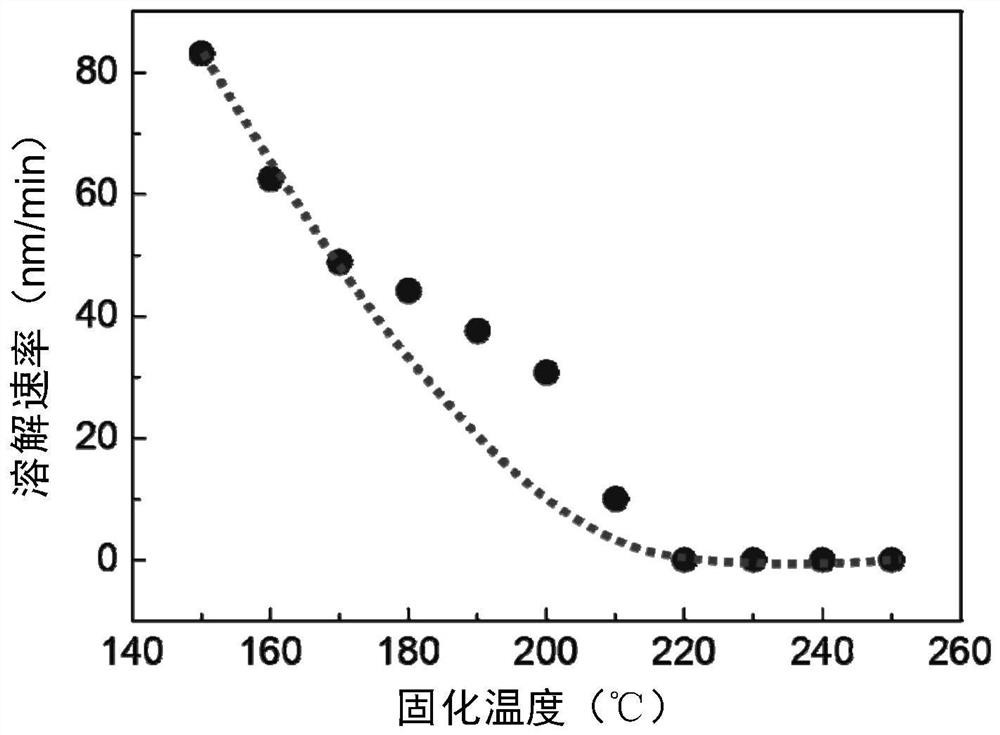

[0046] Taking the common photoresist S1813 in the semiconductor process as an example, it was spin-coated on Si / SiO 2 After being placed on the substrate, heat at 150°C, 160°C, 170°C, 180°C, 190°C, 200°C, 210°C, 220°C, 230°C, 240°C and 250°C for 6 minutes, and then soak the sample in acetone solution After taking it out for 5 minutes, use a step meter to measure the thickness change of the S1813 layer in each sample to determine the better curing temperature. figure 2 It is the relationship graph between the dissolution rate of S1813 in acetone solution and the curing temperature. It can be seen that when the curing temperature is greater than 220°C, the thickness of the S1813 layer hardly changes, indicating that above 220°C is a better curing temperature r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com