A method for manufacturing a Gan-based LED-encapsulated electrode structure

A technology of electrode structure and manufacturing method, which is applied to circuits, electrical components, semiconductor devices, etc., can solve the problems of difficulty in completing side reflections, and the edges of electrodes cannot be effectively and completely covered, and achieve the effect of improving brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

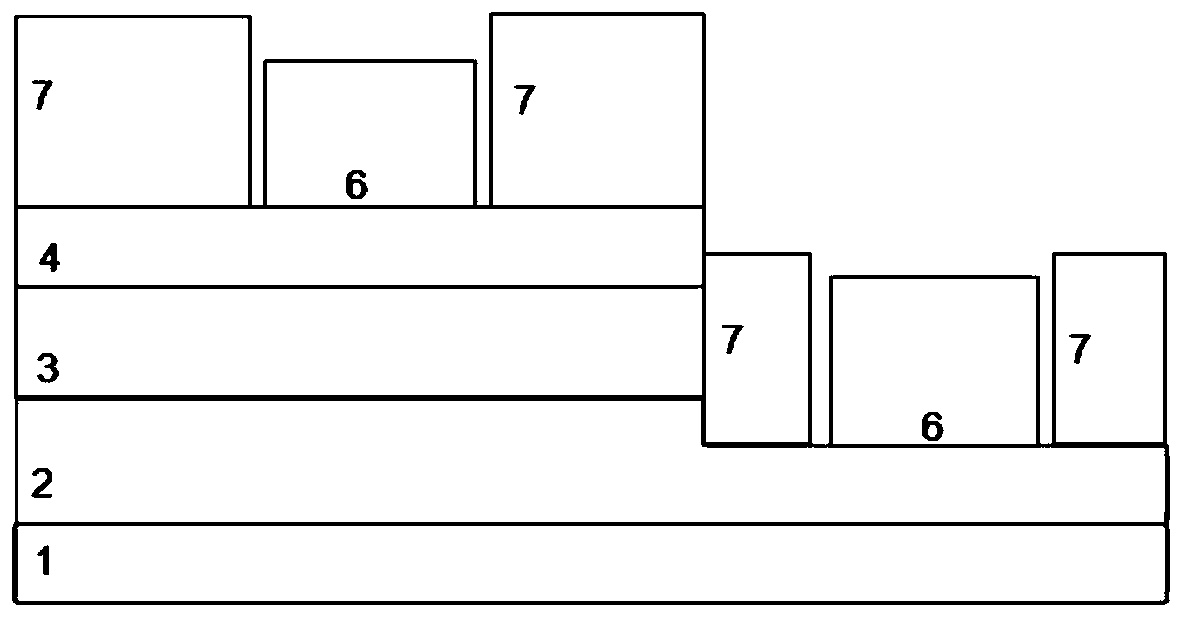

[0056] A method for manufacturing a GaN-based LED coated electrode structure, comprising the following steps:

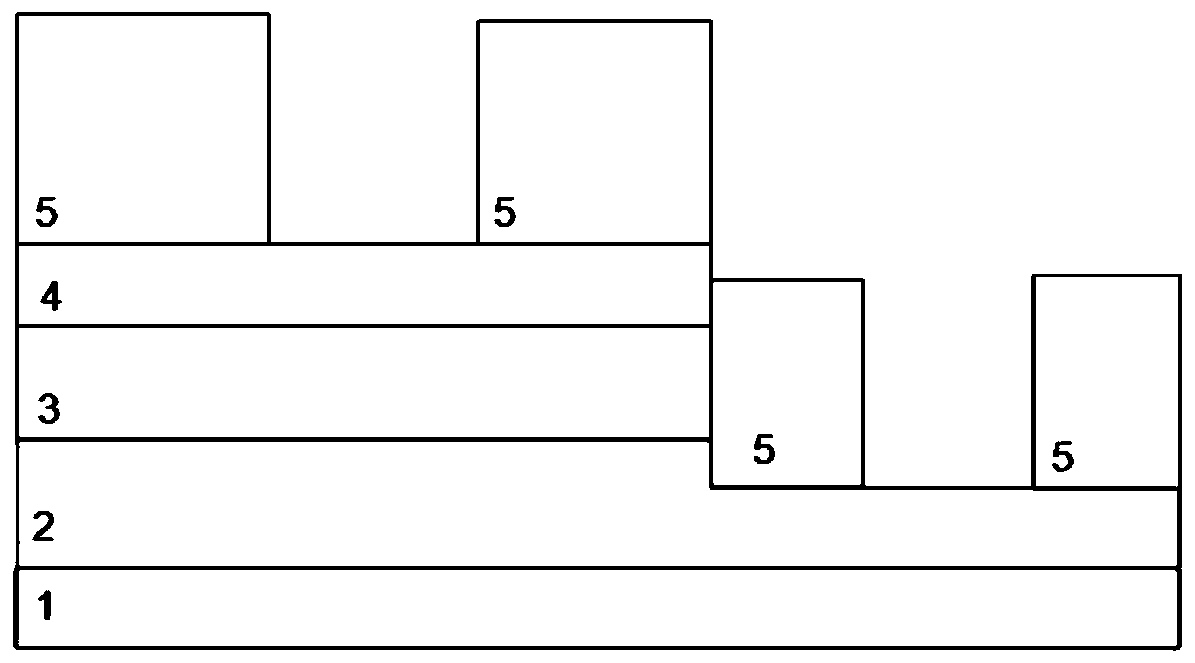

[0057] Step 1, the first photolithography electrode pattern production, on the GaN-based LED wafer, use negative photoresist to make photolithography electrode pattern; figure 1 shown;

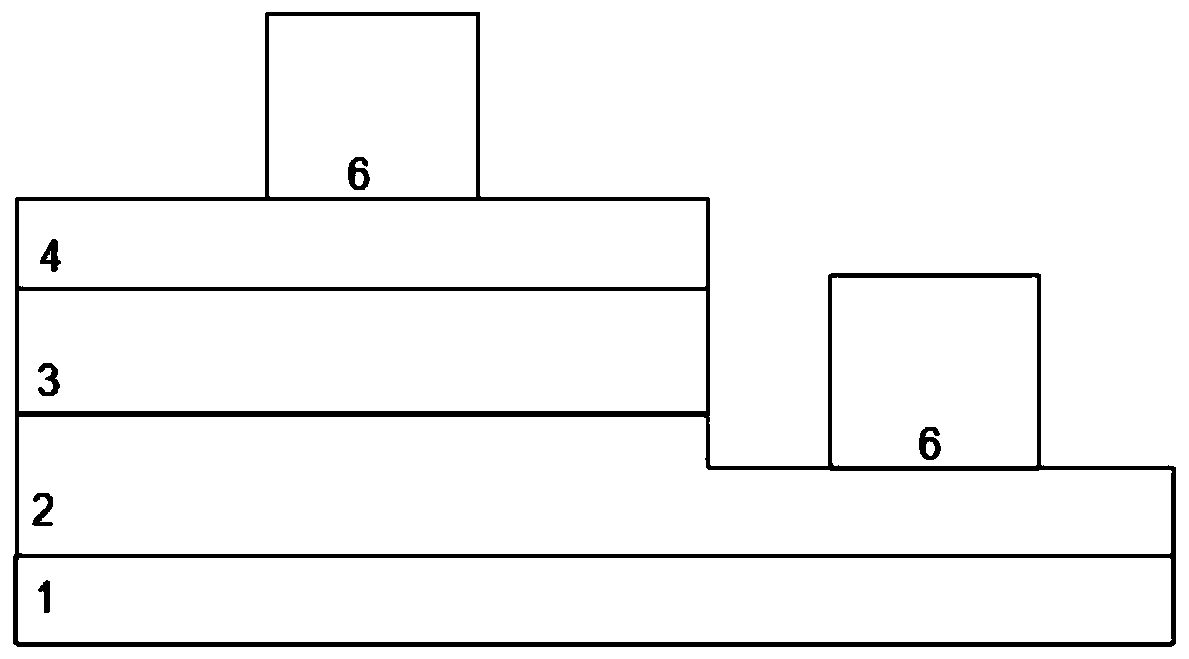

[0058] Step 2, the first evaporation electrode, including:

[0059] Step 2-1, place the wafer completed in step 1 in the chamber of the electron beam evaporation table, and after the vacuum degree reaches 9.0E-6 Torr, evaporate the first Cr layer with a thickness of 5 angstroms, and cool for 3 minutes;

[0060] Step 2-2, performing evaporation of the first Al layer reflector with a thickness of 500 angstroms, and cooling for 3 minutes;

[0061] Step 2-3, performing Ti layer vapor deposition with a thickness of 200 angstroms, and cooling for 3 minutes;

[0062] Step 2-4, conduct Au layer evaporation with a thickness of 3000 angstroms, and cool to room temperature 25°;

[0063] Ste...

Embodiment 2

[0074] A method for manufacturing a GaN-based LED coated electrode structure, comprising the following steps:

[0075] Step 1. The first photolithographic electrode pattern production, using negative photoresist on the GaN-based LED wafer, to produce photolithographic electrode patterns;

[0076] Step 2, the first evaporation electrode, including:

[0077] Step 2-1, place the wafer completed in step 1 in the chamber of the electron beam evaporation table, and after the vacuum degree reaches 9.0E-6 Torr, evaporate the first Cr layer with a thickness of 30 angstroms, and cool for 3 minutes;

[0078] Step 2-2, performing evaporation of the first Al layer reflector with a thickness of 1000 angstroms, and cooling for 3 minutes;

[0079] Step 2-3, performing Ti layer vapor deposition with a thickness of 500 angstroms, and cooling for 3 minutes;

[0080] Step 2-4, conduct Au layer evaporation, the thickness is 5000 Angstrom, cool to room temperature 25 °;

[0081] Step 2-5, use th...

Embodiment 3

[0090] A method for manufacturing a GaN-based LED coated electrode structure, the steps of which are as described in Example 1, except that in steps 2-5, the mass fraction of hydrochloric acid is 36%, and the density of the hydrochloric acid is 1.10 g / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com