Flexible antenna and patch preparation method thereof

A flexible antenna and patch technology, used in antennas, antenna parts, antennas suitable for movable objects, etc., can solve problems such as limited application and no flexibility, and achieve beautiful patterns, good flexibility, and rich colors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

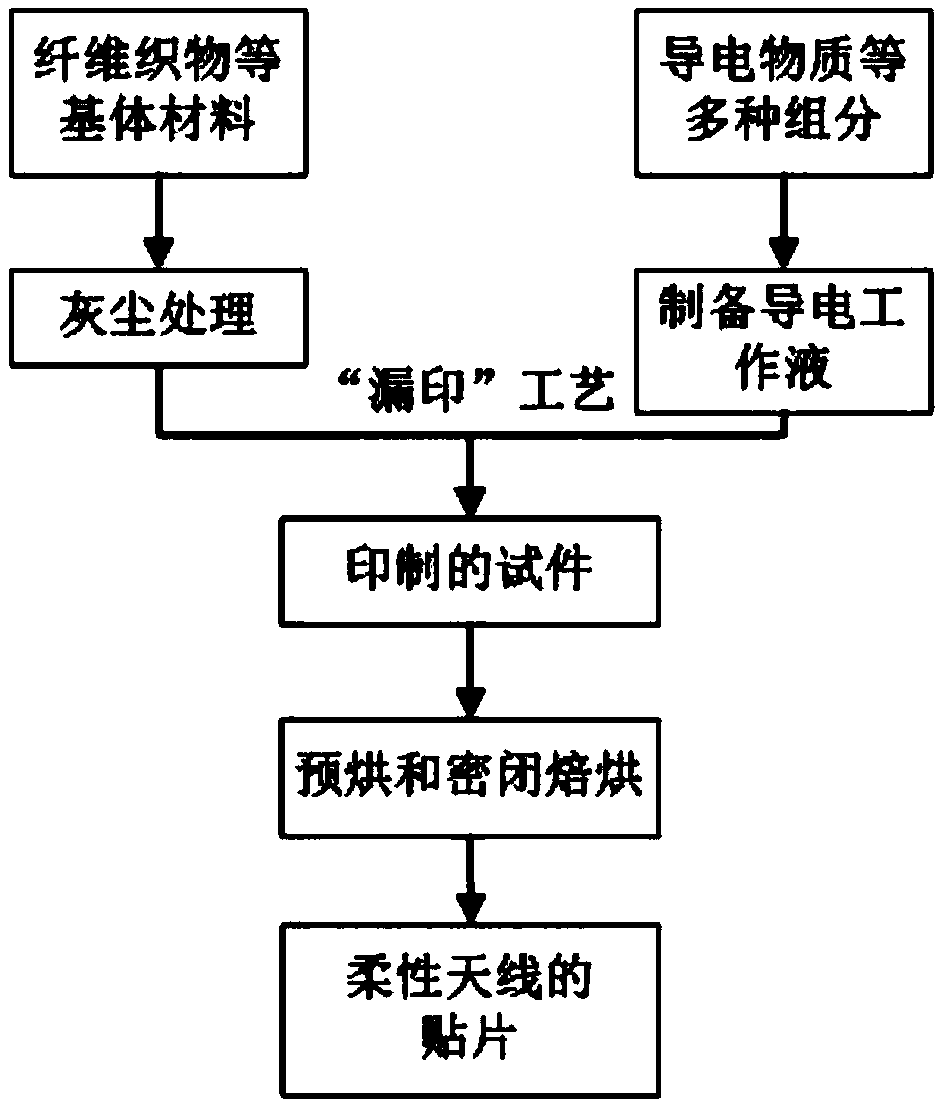

[0028] Such as figure 1 As shown, the specific preparation method of the flexible antenna patch of the present invention includes the following steps:

[0029] 1) First, process the flexible media matrix materials such as fiber fabrics, cut them into suitable sizes, and blow off the dust on the surface in a vacuum environment (0.3-0.5 atmospheres) to eliminate electrostatic effects and reduce the impact of dust on the process and performance The impact

[0030] 2) Fix the flexible medium base material on the printing platen;

[0031] 3) Conductive working fluid is prepared from multiple components according to the following formula;

[0032] 4) Place the conductive working fluid in the color frame of the flat screen or rotary screen printing machine, and the automatic control mechanism controls the automatic lifting, automatic shift and automatic printing of the color frame;

[0033] 5) Using the "missing printing" process, the conductive working fluid is leaked onto the carrier (flex...

Embodiment 1

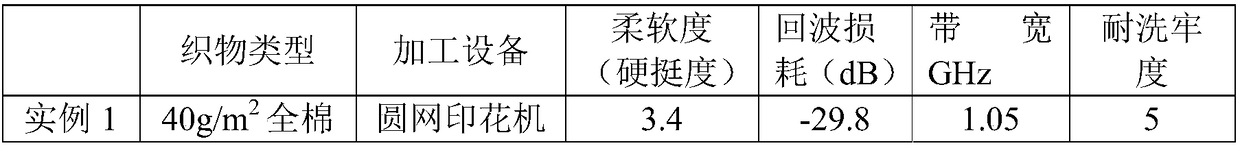

[0050] At 40g / m 2 The cotton plain weave fabric is used as the flexible medium matrix material to prepare the flexible antenna patch. The specific preparation method is as follows:

[0051] 1) Cut the above-mentioned cotton plain weave fabric to a suitable size, and blow off the dust on the surface in a vacuum environment of 0.4 atmospheres to eliminate the electrostatic effect and reduce the influence of dust on the process and performance;

[0052] 2) Fix the processed cotton plain weave fabric on the printing platen;

[0053] 3) Preparation of conductive working fluid:

[0054] ① Conductive component: Weigh 10kg conductive component; among the conductive components, nano silver powder 2 kg, graphene 0.5 kg, nano zinc oxide 0.5 kg, nano copper oxide 1 kg, aluminum oxide 1 kg, nano titanium dioxide 1.5 kg, nano three 1kg of iron oxide, 1kg of tin oxide, 1kg of nano aluminum powder and 0.5kg of zinc chloride;

[0055] ②Binder components: LA132 type water-based adhesive 3kg; water-based...

Embodiment 2

[0065] The difference between this embodiment and embodiment 1 is that this embodiment uses 21g / m 2 Wallpaper is used as a flexible medium base material. In the method steps, infrared pre-baking or oven pre-baking is used for 30 seconds, the pre-baking temperature is about 100°C, the airtight baking is 4 minutes, and the baking temperature is about 118°C to prepare the flexible antenna patch. Then the flexible antenna is processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com