A kind of preparation method of polycarboxylate water-reducing agent for concrete prefabricated components

A technology of prefabricated components and water reducers, which is applied in the field of concrete admixtures, and can solve problems such as excessive air bubbles on the surface, reduced concrete strength in the later stage, and alkali and anti-frost on the surface of concrete products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

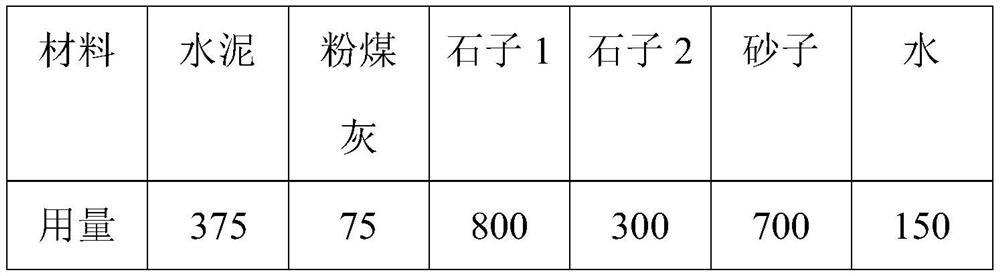

Method used

Image

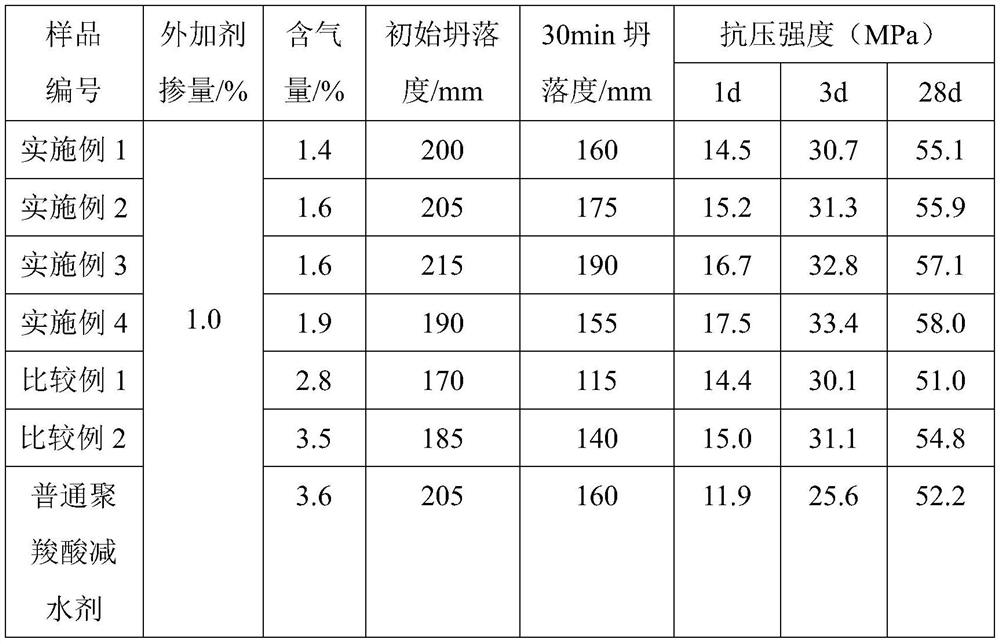

Examples

Embodiment 1

[0042] A preparation method of polycarboxylate water reducer for concrete prefabricated components, comprising the following steps:

[0043] (1) Put 360g of HPEG-2400 and 200g of deionized water into a four-necked flask, stir evenly, and add 1g of ammonium persulfate;

[0044] (2) Mix 0.55gL-ascorbic acid, 2.0g thioglycolic acid, 40g methacrylic acid, 18g monoethanolamine fumarate and 250g deionized water, stir well to form a mixed solution; control the rate of addition of the mixed solution, within 3h After dropping, continue to stir and react for 2 hours, add 182g of water to obtain a 40% solid polycarboxylate superplasticizer mother liquor;

[0045] (3) Add 50 g of the above-prepared polycarboxylate water-reducer mother liquor to 50 g of water, 10 g of melamine water-reducer, and 0.03 g of defoamer, and stir evenly to obtain a polycarboxylate water-reducer for concrete prefabricated components.

Embodiment 2

[0047] A preparation method of polycarboxylate water reducer for concrete prefabricated components, comprising the following steps:

[0048] (1) Put 360g of HPEG-3000 and 200g of deionized water into a four-necked flask, stir evenly, and add 1.5g of azodiisopropylimidazoline hydrochloride;

[0049] (2) Mix 0.8 g of tartaric acid, 1.0 g of mercaptoethanol, 34 g of acrylic acid, 25 g of monoethanolamine fumarate and 250 g of deionized water, and stir evenly to form a mixed solution; control the rate of addition of the mixed solution, drop it within 3 hours, continue After stirring and reacting for 2 hours, 183.5 g of water was added to obtain a 40% solid polycarboxylate superplasticizer mother liquor;

[0050] (3) Add 50 g of the above-prepared polycarboxylate water reducer mother liquor to 50 g of water, 15 g of melamine water reducer, and 0.05 g of defoamer, and stir evenly to obtain a polycarboxylate water reducer for concrete prefabricated components.

Embodiment 3

[0052] A preparation method of polycarboxylate water reducer for concrete prefabricated components, comprising the following steps:

[0053] (1) Put 360g of HPEG-3000 and 200g of deionized water into a four-necked flask, stir evenly, and add 2.8g of hydrogen peroxide;

[0054](2) Mix 0.9g saffron, 1.0g mercaptoacetic acid, 0.9g mercaptoethanol, 5g fumaric acid, 30g acrylic acid, 35g monoethanolamine fumarate and 250g deionized water, stir well to form a mixed solution; Mix the solution to control the dropping rate, finish dropping within 3 hours, continue to stir and react for 2 hours, then add 196.5g of water to obtain a 40% solid polycarboxylate superplasticizer mother liquor;

[0055] (3) Add 50 g of the above-prepared polycarboxylate water reducer mother liquor to 50 g of water, 18 g of melamine water reducer, and 0.06 g of defoamer, and stir evenly to obtain a polycarboxylate water reducer for concrete prefabricated components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com