Nano seed crystal early strength agent and preparation method thereof

A technology of nano-crystal seed and early strength agent, which is applied in the preparation of nano-crystal seed early-strength agent, nano-crystal seed early-strength agent, and early-strength agent. It can solve the problems of not giving guidance and shortening the demoulding time of concrete. , to achieve the effect of shortening demoulding time, improving mechanical properties and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

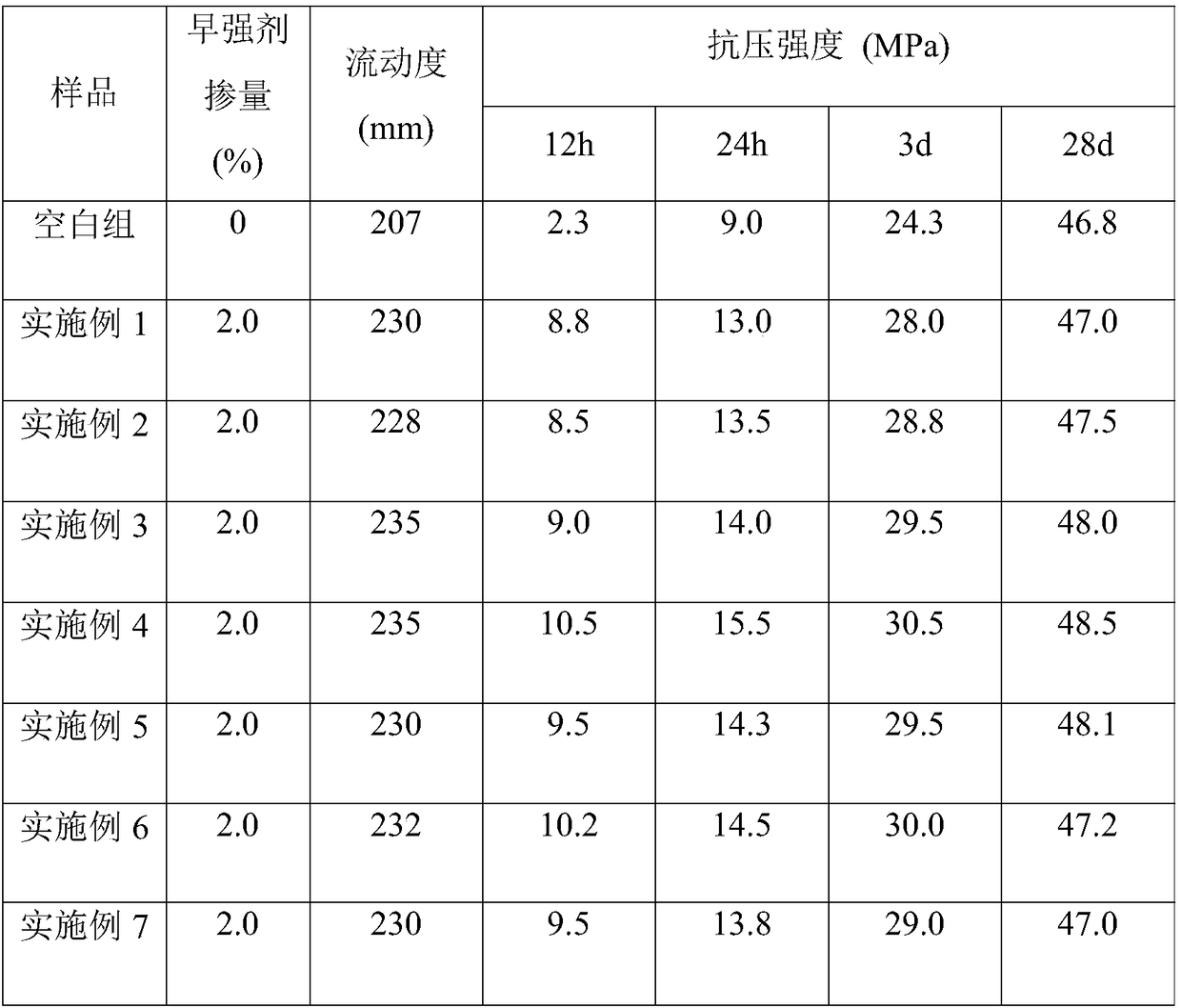

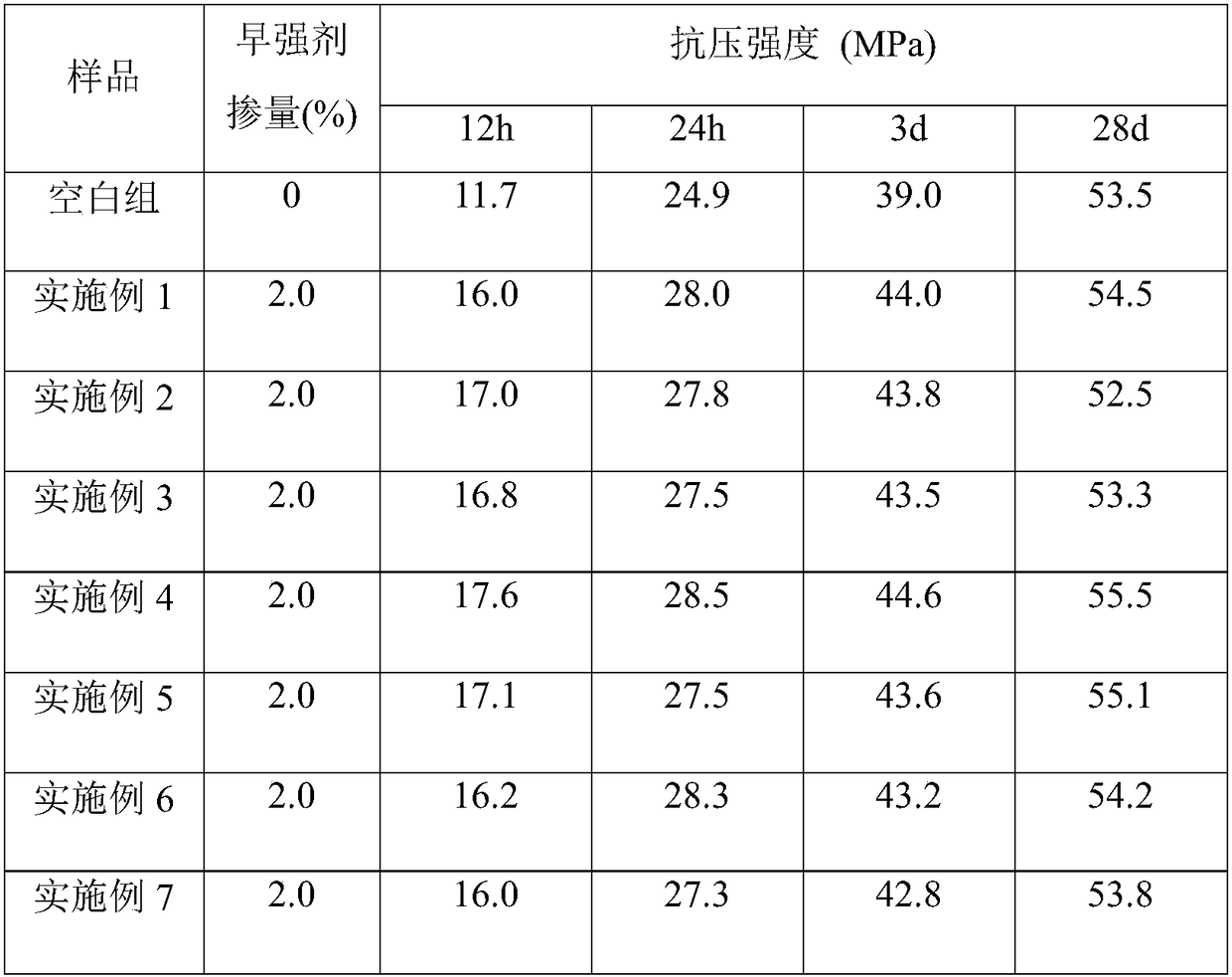

Examples

Embodiment 1

[0019] Embodiment 1: the nano-crystal seed early-strength agent of the present invention is to prepare the high molecular polymer dispersion liquid first, and then prepare the nano-crystal seed early-strength agent, specifically:

[0020] The high-molecular polymer dispersion is made of the following components and raw materials in parts by mass: 100 parts of polyether macromonomer with a weight-average molecular weight of 2400, namely isopentenol polyethylene glycol monomethyl ether, Silane coupling agent is 4.4 parts of vinyltriethoxysilane, unsaturated carboxylic acid is 12 parts of acrylic acid, chain transfer agent is 0.55 part of mercaptopropionic acid, initiator is 0.6 part, deionized water, initiator is 0.1 part of ascorbic acid and A combination of 0.5 parts hydrogen peroxide. The preparation method of the high molecular polymer dispersion comprises the following process steps: adding prenyl alcohol polyethylene glycol monomethyl ether, vinyl triethoxysilane and 67 pa...

Embodiment 2

[0022] Embodiment 2: the nano-crystal seed early-strength agent of the present invention is to prepare the polymer dispersion liquid first, and then prepare the nano-crystal seed early-strength agent, specifically:

[0023] The components, parts by mass and preparation method of the polymer dispersion are the same as in Example 1.

[0024] The preparation method of described nano-crystal seed early-strength agent comprises the following process steps: 1. get 10 parts of above-mentioned macromolecular polymer dispersion liquid, 150 parts of deionized waters and join in the reactor (500ml there-necked flask), start temperature controller and Stirrer, adjust the rotating speed of the stirrer to 400rpm, and dropwise add NaOH solution with a mass percentage concentration of 30% to adjust the pH to 7.0; Ionized water is made into C feed solution; 12 parts of inorganic calcium raw materials, namely calcium nitrate tetrahydrate, are weighed, and the calcium-silicon ratio (molar ratio)...

Embodiment 3

[0025] Embodiment 3: the nano-crystal seed early-strength agent of the present invention is to prepare the polymer dispersion liquid first, and then prepare the nano-crystal seed early-strength agent, specifically:

[0026] The components, parts by mass and preparation method of the polymer dispersion are the same as in Example 1.

[0027] The preparation method of described nano-crystal seed early-strength agent comprises the following process steps: 1. get 10 parts of above-mentioned macromolecular polymer dispersion liquid, 150 parts of deionized waters and join in the reactor (500ml there-necked flask), start temperature controller and Stirrer, adjust the rotating speed of the stirrer to 400rpm, and dropwise add NaOH solution with a mass percentage concentration of 30% to adjust the pH to 7.0; Ionized water is made into C feed solution; 18 parts of inorganic calcium raw materials, namely calcium nitrate tetrahydrate, are weighed, and the calcium-silicon ratio (molar ratio)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com