Preparation method of alkali-soluble polysaccharide of enteromorpha

An alkali-soluble and proliferative technology, which is applied in the field of preparation of prolifera alkali-soluble polysaccharide, can solve the problems of complicated steps, unsuitable for industrialized production, and high cost, and achieves high operability, is beneficial to development and utilization, and has low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

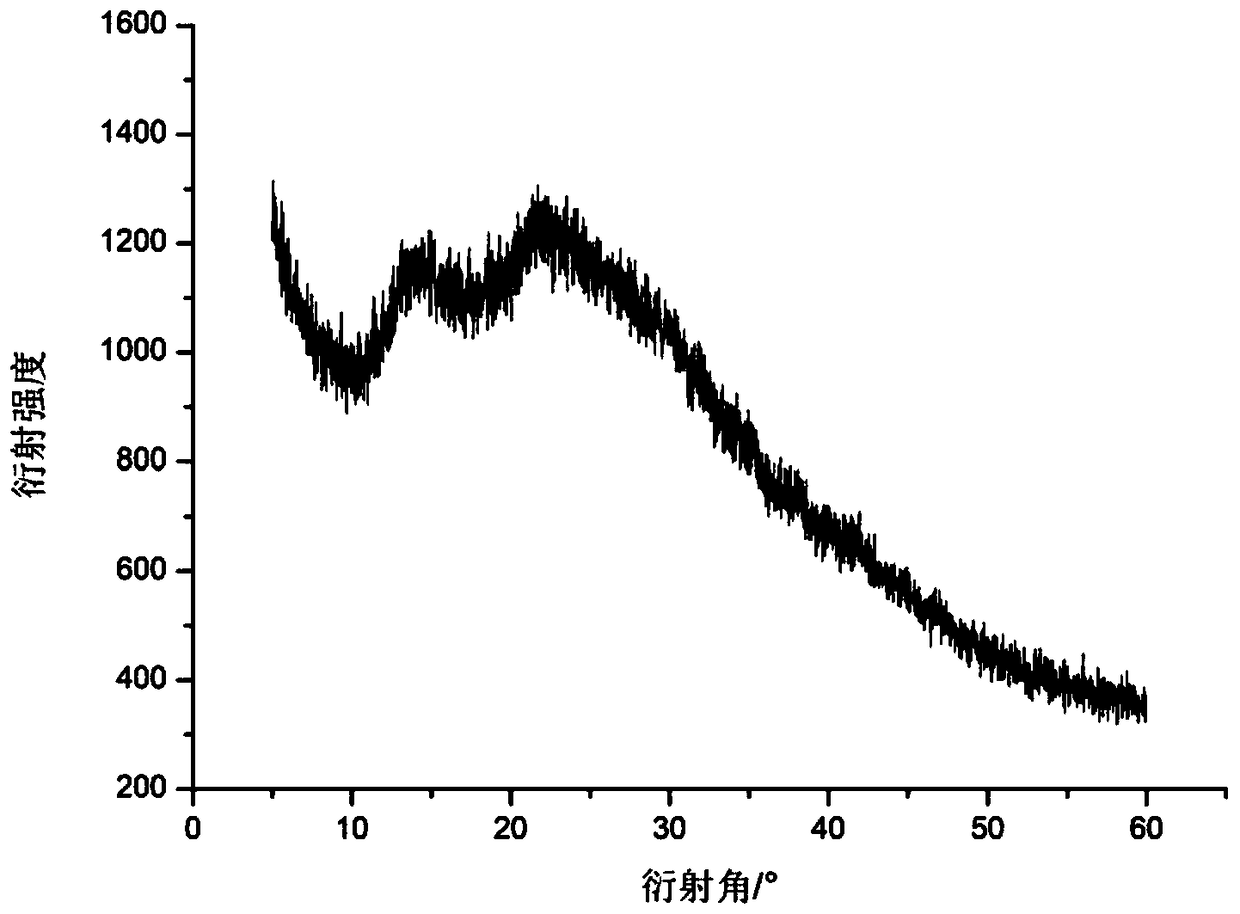

Image

Examples

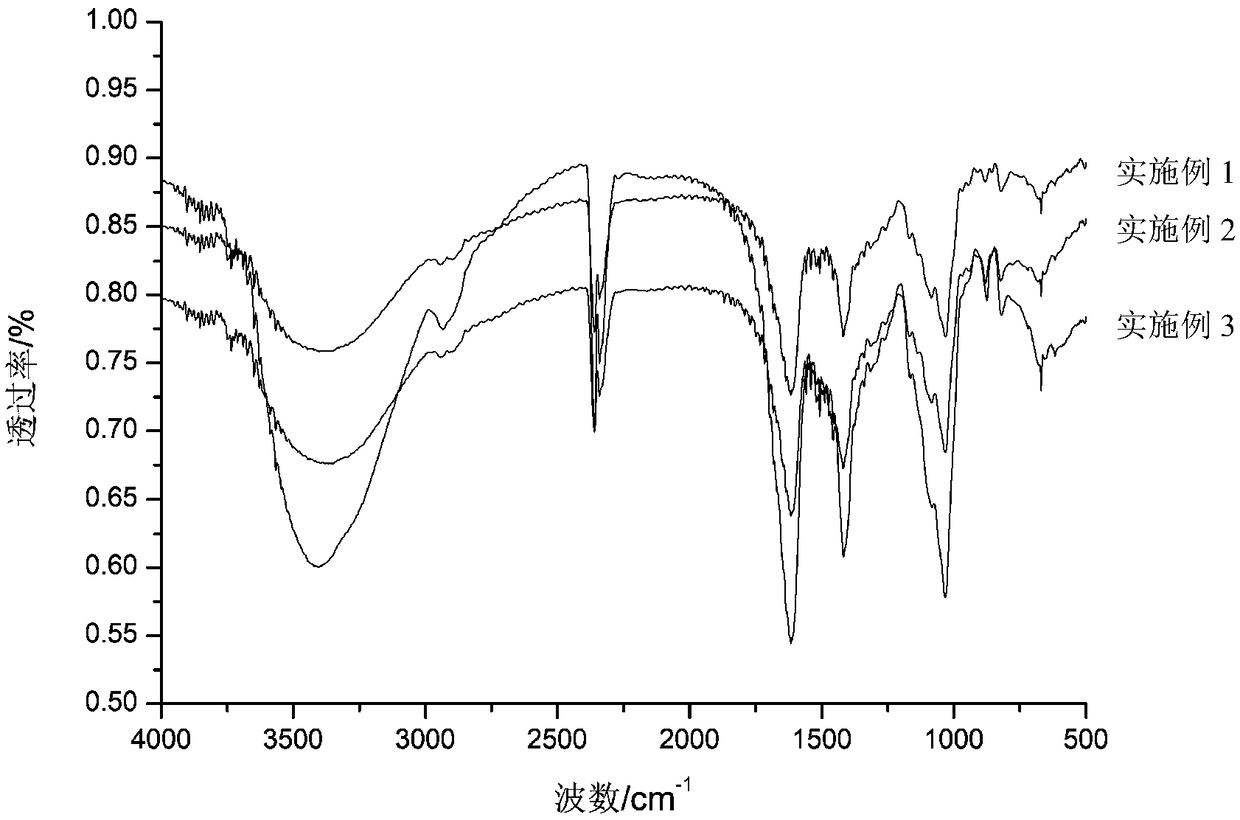

Embodiment 1

[0029] The preparation method of the enteromorpha alkali-soluble polysaccharide provided by the present embodiment comprises the following steps:

[0030] a. Wash the fresh Enteromorpha with water to remove the silt, and dry it at 45°C. The dried sample is pulverized by a pulverizer and passed through a 40-mesh sieve.

[0031] b. After mixing 100g of dry powder of Enteromorpha enteromorpha with 1000mL of 80% ethanol solution, ultrasonically treat at 60°C for 1 hour, filter and dry after the reaction.

[0032] c. Take the powder of Enteromorpha after heat reflux drying, heat reflux in 5000mL aqueous solution, react at 90°C for 2 hours, collect the residue, wash with hot water 3 times, and collect the residue.

[0033] d. Add the obtained residue to the compound enzyme solution (the ratio of cellulase and neutral protease is 1:1) at a solid-to-liquid ratio of 1:40 by weight, adjust the pH to 8.0, and react at 55°C for 80 minutes.

[0034] e. After the enzymatic hydrolysis react...

Embodiment 2

[0041] The preparation method of the enteromorpha alkali-soluble polysaccharide provided by the present embodiment comprises the following steps:

[0042] a. Wash the fresh Enteromorpha with water to remove the silt, and dry it at 45°C. The dried sample is pulverized by a pulverizer and passed through a 40-mesh sieve.

[0043] b. After mixing 50g of dry enteromorpha powder with 500mL of 80% ethanol solution, ultrasonically treat at 60°C for 1 hour, filter and dry after the reaction is completed.

[0044] c. Heat reflux dried Enteromorpha powder in 2500mL aqueous solution, react at 90°C for 2 hours, collect the residue, wash 3 times with hot water, and collect the residue.

[0045] d. Add the obtained residue to the compound enzyme solution (the ratio of cellulase and neutral protease is 1:1) at a solid-to-liquid ratio of 1:40 by weight, adjust the pH to 8.0, and react at 55°C for 80 minutes.

[0046] e. After the enzymatic hydrolysis reaction, centrifuge at 5000rpm for 10min to...

Embodiment 3

[0052] Embodiment 3 comparative experiment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com