Starch syrup purification and concentration method

A technology for starch syrup and syrup, which is applied in the production of sucrose, sugar, and sugar, can solve the problems of long heating time, low concentration efficiency, affecting the purification effect, etc., to reduce the amount of extra steam and achieve high purity. , the effect of increasing the concentration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

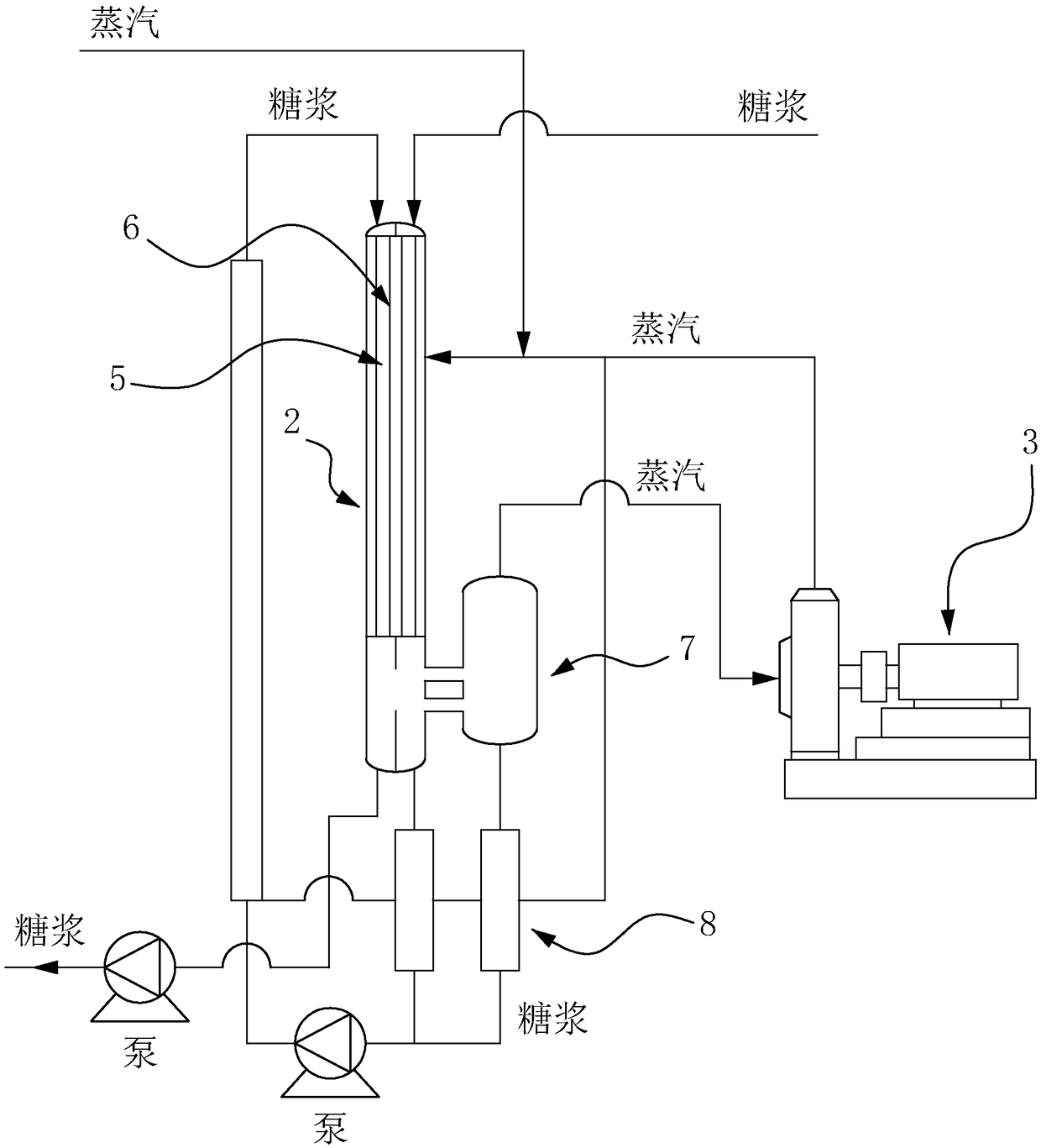

[0035] refer to Figure 1 to Figure 3 The method for purifying and concentrating starch syrup is further described.

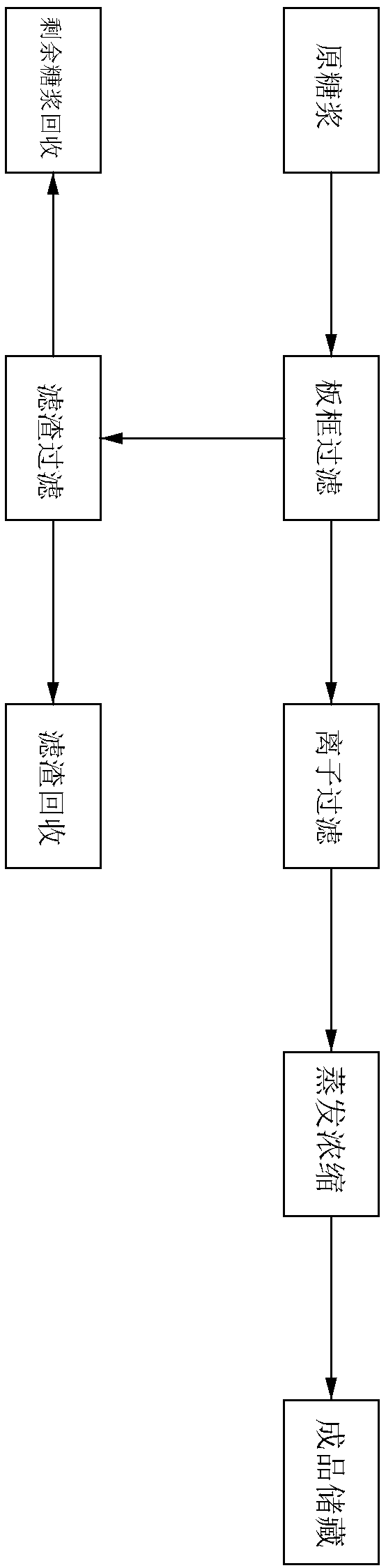

[0036] A method for purifying and concentrating starch syrup, combining figure 1 , including the following steps:

[0037] ① Plate and frame filtration: adding dilute hydrochloric acid or dilute soda ash to the syrup to adjust the pH value between 4.8-5.0 to carry out protein isoelectric point coagulation on the saccharification solution in the previous process, then add filter aid and mix evenly, and pass the mixed syrup into the plate Frame filter press for press filtration. Specifically, the filter aid includes perlite filter aid and activated carbon powder, and the two are mixed at a ratio of 1:1; the dosage of the filter aid accounts for 0.5%-1% of the syrup mass.

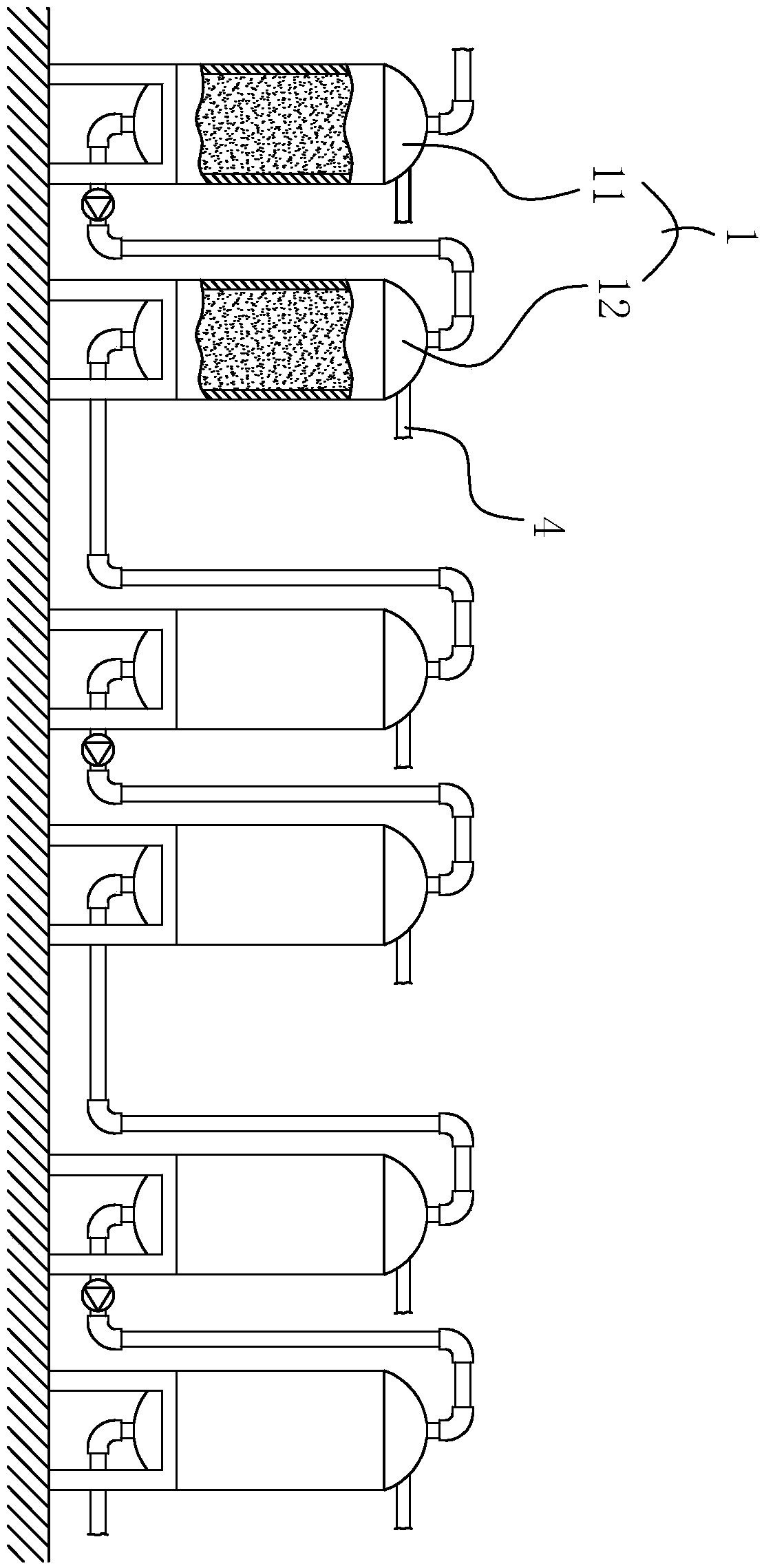

[0038] ②Ion filtration: combined with figure 2 , pass the filtered syrup in step ① into several groups of ion exchanger groups 1 to remove impurity ions in the syrup; specifically, the ion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com