Sensitive material for detecting acetone gas and preparation method thereof

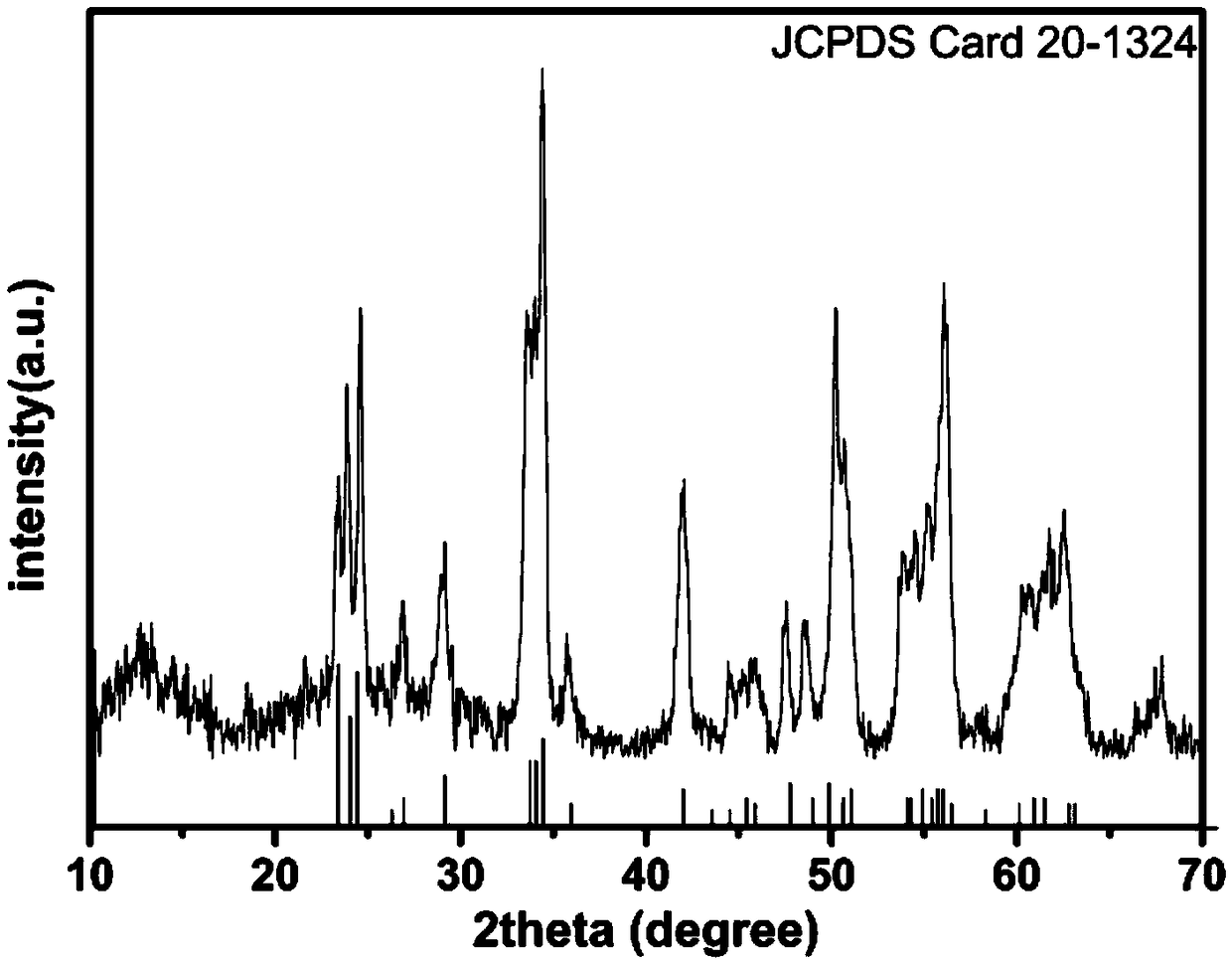

A technology of sensitive materials and gas-sensitive materials, which is applied in the detection of acetone gas sensitive materials and its preparation, and in the field of sensitive materials can solve the problems of slow response recovery, poor anti-interference ability, and low sensitivity, and achieve fast response recovery and detection performance. Enhanced, high-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method for a sensitive material for efficiently detecting acetone gas, comprising the steps of:

[0038] 1) Dissolve 0.4g P123 in 80ml of absolute ethanol solution, then add 0.8g WCl 6 Evenly dispersed in the solution, stirring until WCl 6 Dissolve completely;

[0039] 2) Put the final solution obtained in step 1) into the lining of a 100ml reactor, place the reactor in a high-temperature oven, heat it up to 180°C, keep it warm for 2 hours, and then cool down naturally;

[0040] 3) centrifuging and washing the mixed solution in step 2) for several times to collect the centrifuged product, then drying at constant temperature, and collecting the dried product;

[0041] 4) Weigh chitosan and melamine with a mass ratio of 1:4, put them into a porcelain boat and calcinate at 550°C for 3 hours;

[0042] 5) Take 15 mg of the product of step 4) and add it to 100 ml of isopropanol, and put it into a 30KHz ultrasonic cleaner for 2 hours;

[0043] 6) centrifuge t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com