Lithium ion battery, surface-modified ternary material and preparation method

A surface modification and modification technology, which is applied in the direction of electrical components, battery electrodes, secondary batteries, etc., can solve problems such as the inability to evenly distribute coatings, achieve improved stability and processing performance, improve performance, and controllable thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing a surface-modified ternary positive electrode material according to an embodiment of the present invention includes:

[0030] S1: Place the ternary cathode material pretreated under preset process conditions in an atomic layer deposition reaction chamber filled with a specified atmosphere.

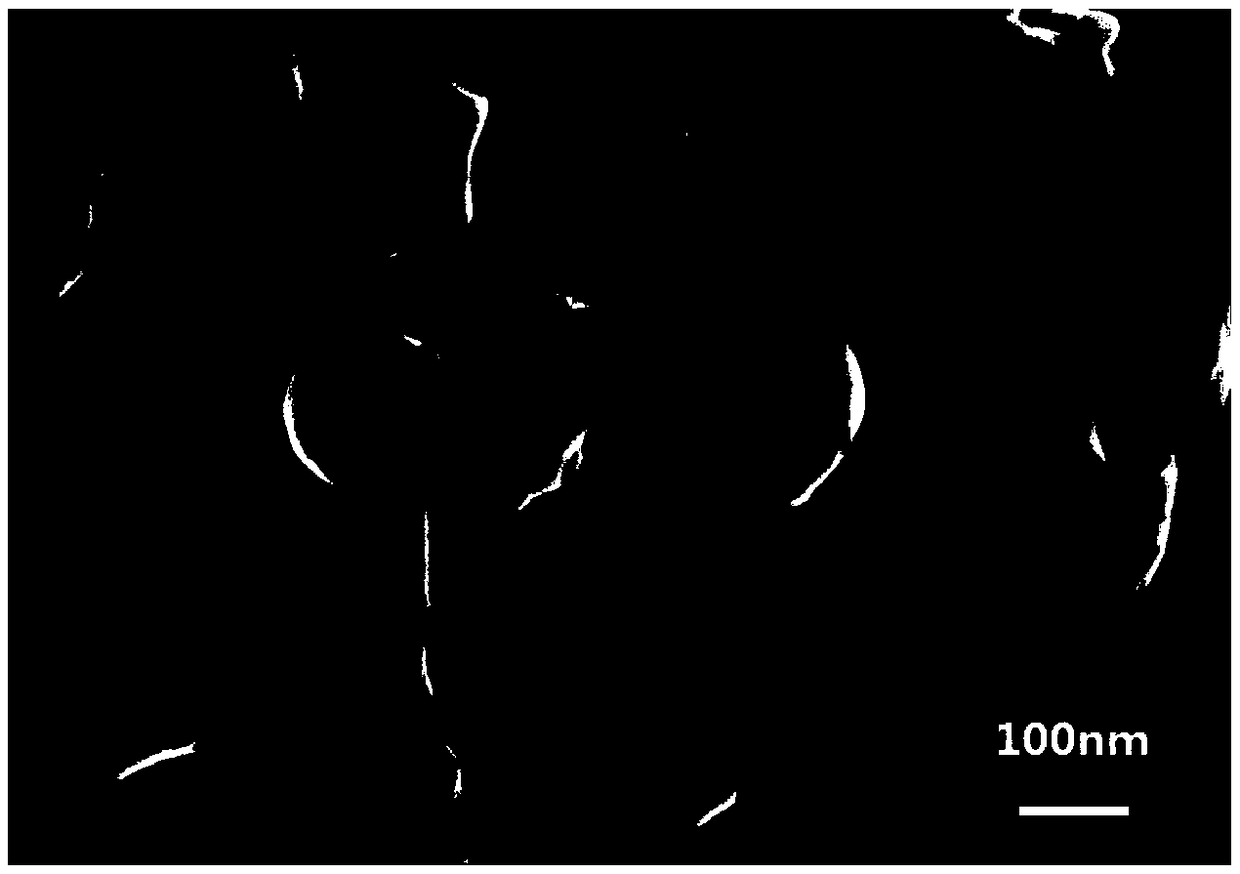

[0031] The ternary cathode material is composed of nickel, cobalt, manganese and three transition metal elements as the main elements, and the general formula is expressed as LiNi x co y mn z o 2 (0≤x,y,z<1). The morphology of the ternary positive electrode material in this embodiment includes single crystal morphology or secondary particle morphology.

[0032] The preset process conditions of this embodiment include: drying in the temperature range of 100°C to 150°C for 6h to 12h, so as to fully remove the moisture of the ternary positive electrode material, so as to improve the surface coating effect of the ternary positive electrode material, and reduce...

Embodiment 1

[0052] Will LiNi 0.84 co 0.1 mn 0.06 o 2 After drying in the temperature range of 120°C for 10h, put it into the atomic layer deposition reaction chamber filled with dry air in advance, raise the temperature of the reaction chamber to keep the temperature at 150°C, and then vacuumize the reaction chamber for 10s; nitrogen is the carrier and Trimethylborane forms a carrier fluid, which is passed into the above-mentioned reaction chamber, and the reaction time is controlled to be 1s. After the reaction, continue to pass into nitrogen for cleaning for 10s; then the H 2 Mix O and nitrogen to form a carrier gas flow, pass it into the above reaction chamber, and control the reaction time for 1 second, continue to pass nitrogen gas for cleaning for 8 seconds after the reaction; then continue to mix butyl lithium and nitrogen gas to form a carrier flow, pass it into the above reaction chamber, The time is controlled at 2s, and after the reaction is completed, continue to feed nitro...

Embodiment 2

[0055] The ternary material is LiNi 0.6 co 0.2 mn 0.2 o 2 The drying condition is 120°C / 12h; the temperature of the reaction chamber is 120°C; the vacuum is pumped for 20s; the organic boron source is triethylborane, the reaction time is 4s, and the cleaning time is 20s; 2 The reaction time after O is 0.05s, and the cleaning time is 0.5s; the organolithium salt is ethyllithium, the reaction time is 4s, and the cleaning time is 50s; 2 The reaction time after O is 0.05s, and the cleaning time is 0.5s; repeat the coating step 6 times, and the others are the same as in Example 1 to obtain the surface modified ternary positive electrode material B, the thickness of the coating layer is 1.2nm, corresponding to the button lithium Ion battery B1, soft pack lithium-ion battery B2.

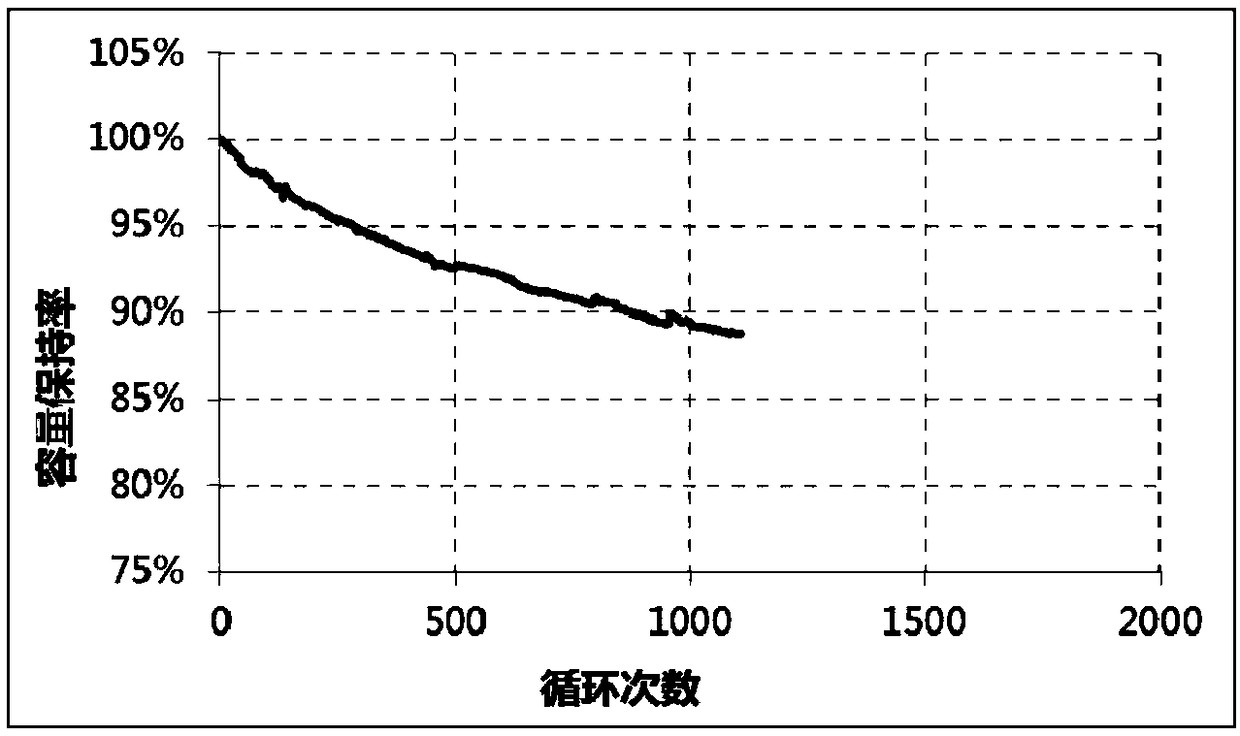

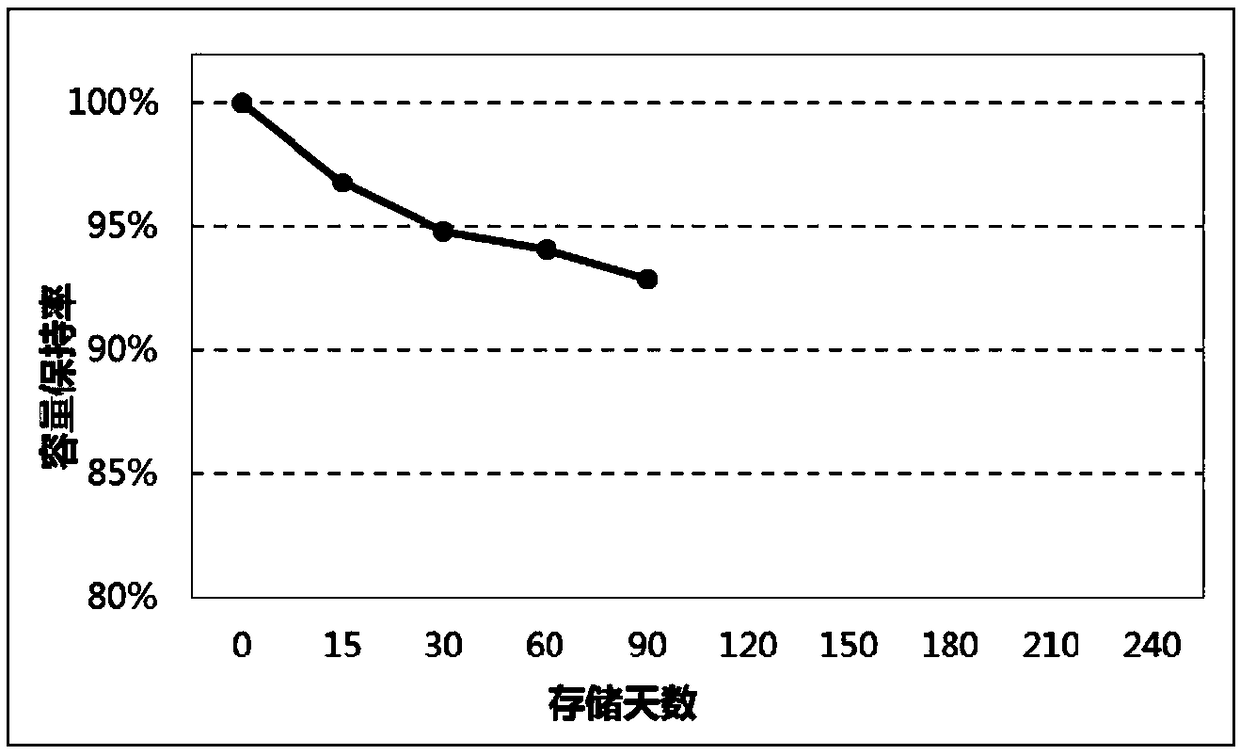

[0056] The gram capacity of the button lithium-ion battery B1 can reach 177mAh / g. The electrical performance test results of the soft-pack lithium-ion battery B2 are: at 50% SOC, the DC internal resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com