Formaldehyde degradation and deodorization additive, preparation method and application thereof

An additive and aldehyde-decomposing technology, which is applied in the field of air purification, can solve problems such as short action time, impact on health, and by-products, and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

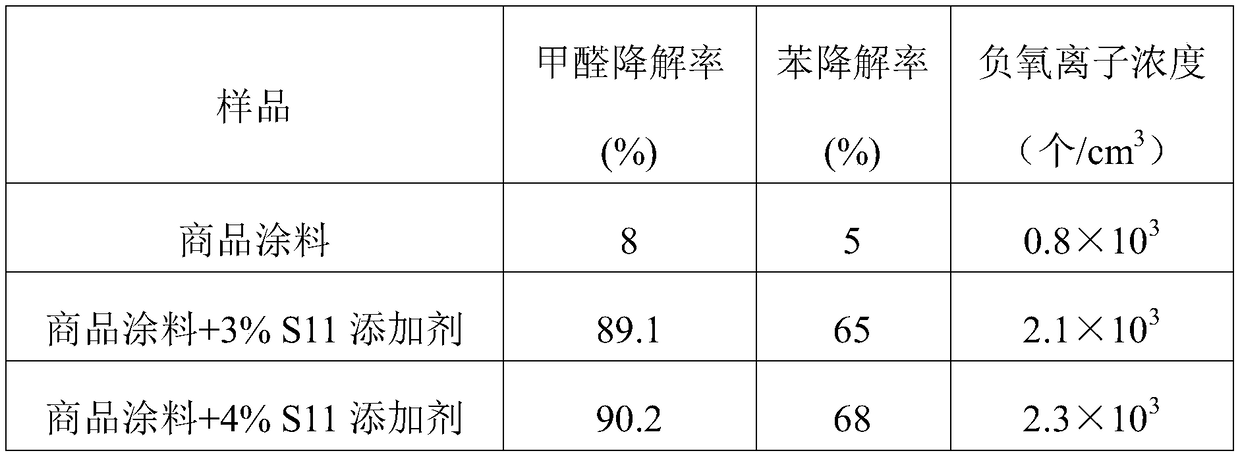

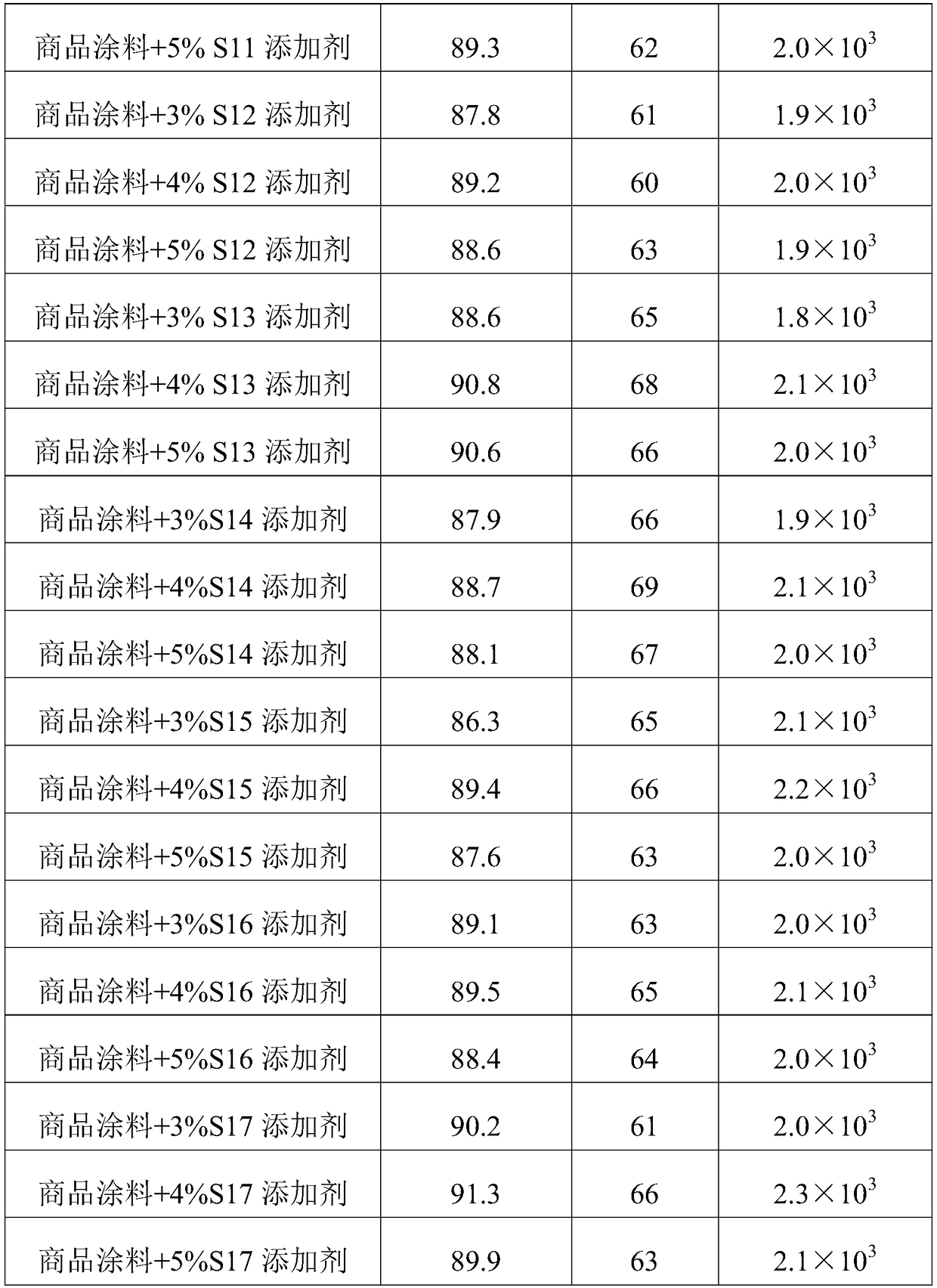

Examples

preparation example Construction

[0022] On the other hand, the specific embodiment of the present invention also provides a preparation method of the above-mentioned additive. The preparation method includes: S1, heating water to the first temperature, adding inorganic oxides under high-speed dispersion stirring, stirring and dispersing; S2, sequentially adding graphite Stir and disperse the alkene, medical stone, and nano-silver, and lower the temperature to the second temperature; S3, add silicon latex and fluorocarbon emulsion in sequence, mix and stir, then add a thickener to obtain an additive.

[0023] Specifically, the preparation method of the additive includes: S1, heating water with a mass fraction of 40% to 50% to the first temperature, adding an inorganic oxide with a mass fraction of 5% to 15% under high-speed dispersion stirring, stirring and dispersing; S2, Adding graphene with a mass fraction of 0.5% to 1%, medical stone with a mass fraction of 30% to 40%, and nano-silver with a mass fraction o...

Embodiment 1

[0028] The aldehyde deodorizing additive of the present embodiment is made through the following steps:

[0029] S1. Heat deionized water with a mass fraction of 45% to 48°C, disperse and stir at a high speed at a speed of 3000r / min, add zinc oxide with a mass fraction of 3% and stir for 10 minutes, then add 2% zinc oxide Stir and disperse tin oxide for 10 minutes, then add titanium dioxide with a mass fraction of 3% and stir and disperse for 10 minutes, and mix well; S2, add 0.6% graphene and stir and disperse for 10 minutes, then add medical stone with a mass fraction of 35% Stir and disperse for 10 minutes, then add nano-silver with a mass fraction of 0.2%, stir and disperse for 10 minutes, mix well, and cool down to 30°C; S3, add 6% silicon latex and stir for 10 minutes, then add 5% The fluorocarbon emulsion was stirred and dispersed for 10 minutes, and after mixing evenly, it was transferred to a nanobelt magnetic roller sand mill, and a 0.2% hydrogen propyl fiber thicken...

Embodiment 2

[0031] The aldehyde deodorizing additive of the present embodiment is made through the following steps:

[0032] S1. Heat deionized water with a mass fraction of 40% to 50°C, disperse and stir at a high speed at a speed of 2000r / min, add zinc oxide with a mass fraction of 2%, stir and disperse for 20 minutes, and then add 1% zinc oxide Stir and disperse tin oxide for 20 minutes, then add 2% titanium dioxide, stir and disperse for 20 minutes, and mix evenly; S2, add 0.5% graphene, stir and disperse for 20 minutes, then add medical stone with a mass fraction of 40% Stir and disperse for 10 minutes, then add nano-silver with a mass fraction of 0.5%, stir and disperse for 30 minutes, mix well, and cool down to 30°C; S3, add 5% silicon latex and stir for 20 minutes, then add 10% The fluorocarbon emulsion was stirred and dispersed for 20 minutes. After mixing evenly, it was transferred to a nanobelt magnetic rolling sand mill, and a polyurethane thickener with a mass fraction of 0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com