A device and a method for high throughput representation of microscopic interface performance of a single fiber and resin

A single fiber, interfacial performance technology, applied in the measurement device, material analysis by optical means, and the use of applied stable tension/pressure to test the strength of materials, etc. The microscopic morphology of the fiber interface, high cost, and low recognition are problems, so as to achieve the effect of simple and effective sample preparation and testing, shortening the development cycle and improving testing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

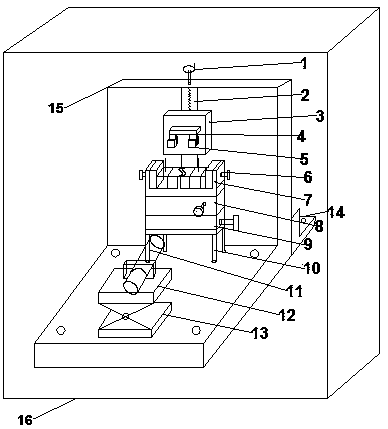

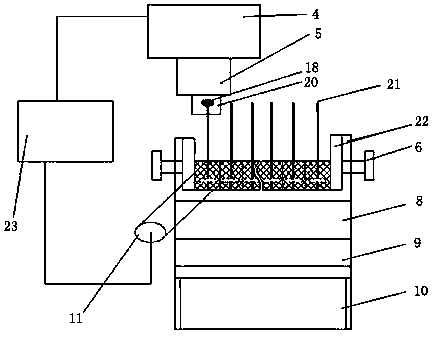

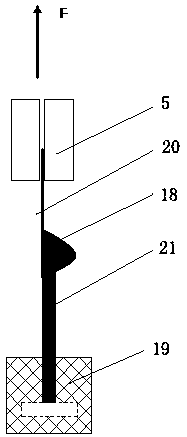

[0051] A kind of specific embodiment of the present invention is as follows:

[0052] After studying the mixing of nitric acid and sulfuric acid, the carbon fiber surface is treated with the mixed acid solution to enhance the adhesion between the carbon fiber and the resin. The optimal time for the mixed acid solution to treat the carbon fiber surface needs to be verified experimentally. Experimental material: PAN-based AKSAca A-42 carbon fiber with a density of 1.78g / cm 3 , a single wire diameter of 7um; EPR-L20 epoxy resin. Select 40 monofilament A-42 carbon fibers with a length of 20mm, put them into the mixed acid for treatment, the treatment time is 15 minutes to 60 minutes, and the interval is 15 minutes, 10 pieces are treated each time, and the surface of the treated carbon fibers is rinsed with water. When the pH of the surface is 7, then put the monofilament into the fixture and the mold, add resin into the groove of the mold, and prepare a mold with 40 single fibers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com