Series of instant-brewing- white-fungus fruit-juice beverage paste and preparation method thereof

A technology of white fungus and series, which is applied in the field of ready-to-fill series white fungus juice beverage sauce and its preparation, can solve the problems of gap, loss, uneconomical drinking of fruit juice beverages, etc., and achieves the effect of reducing transportation cost, good effect and wide drinking population.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

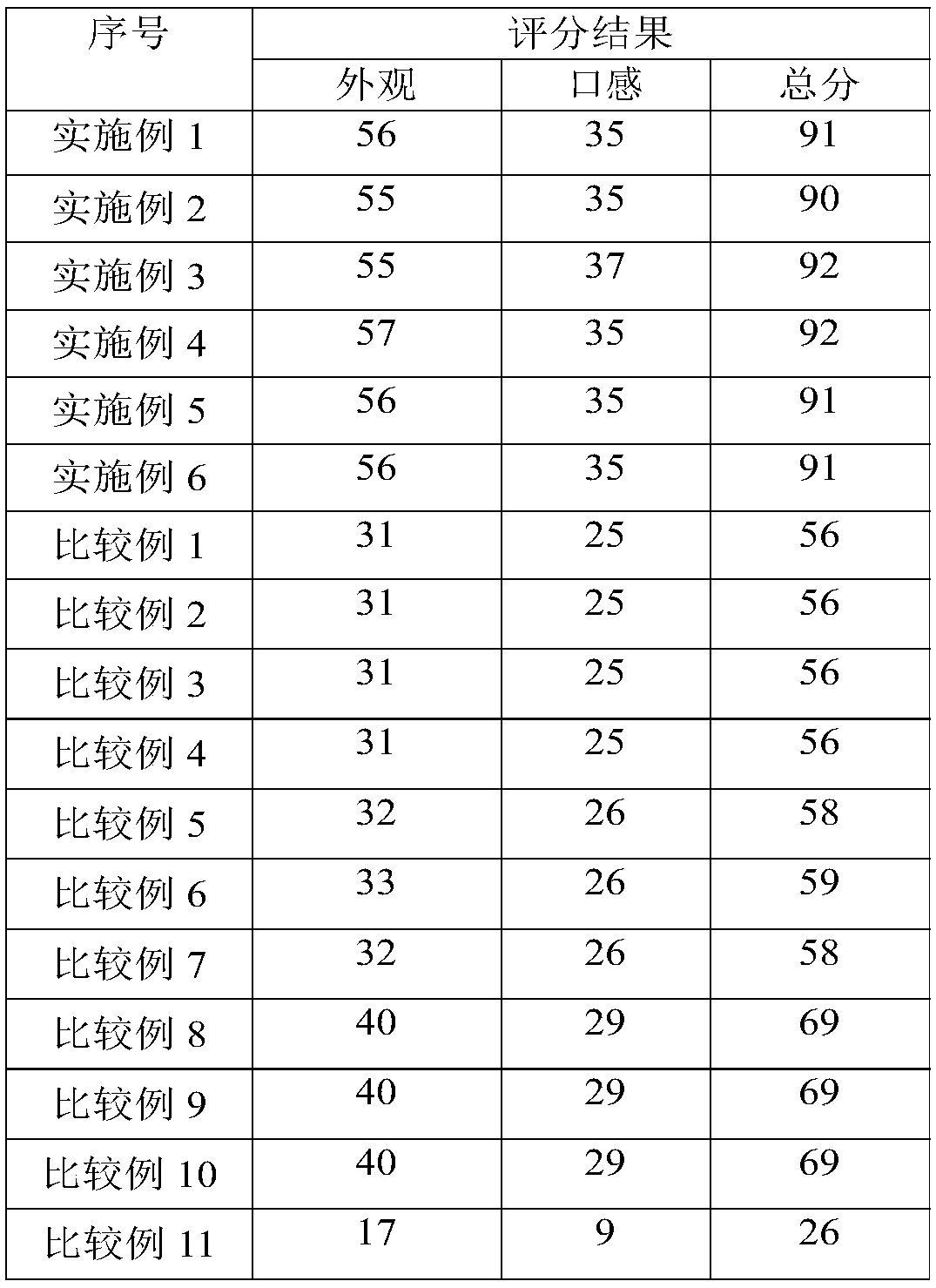

Embodiment 1

[0051] The technological preparation step of white fungus juice drink sauce is carried out according to the following steps:

[0052] Raw material formula: 60 kg of soaked fresh white fungus, 200 kg of apple, 5 kg of rock sugar, 100 kg of sucrose, 4 kg of honey, 0.2 kg of kudzu root powder, 1 kg of sodium dihydrogen phosphate, 0.8 kg of citric acid, 1.5 kg of sodium D-isoascorbate, 0.02 kg of pectinase, 0.05 kg of cellulase, 0.04 kg of glucose oxidase, 1 kg of food flavor;

[0053] Step 1: Wash the fresh white fungus soaked for 1-2 hours with clean water, remove the ear shells, filter the surface water, weigh them, and cut them into 2-3 cm small pieces for later use. Put the cleaned fruits into a pelletizer and cut them into 0.2cm granular small pieces, weighed for later use, the kudzu root powder is ground to obtain the kudzu root powder, and the kudzu root slurry is made into the kudzu root slurry with the mass ratio of 5:5 with water;

[0054] Step 2: Vacuum freeze-dry the...

Embodiment 2

[0060] The technological preparation step of white fungus juice drink sauce is carried out according to the following steps:

[0061] Raw material formula: 20 kg of soaked fresh white fungus, (5 parts of apple, 3 parts of pineapple, 2 parts of red date) 300 kg in total, 15 kg of rock sugar, 150 kg of sucrose, 7 kg of honey, 0.3 kg of kudzu root powder, 2 kg of sodium dihydrogen phosphate, 0.1 kg of citric acid, 2 kg of sodium D-isoascorbate, 0.01 kg of pectinase, 0.1 kg of cellulase, 0.02 kg of glucose oxidase, 2 kg of food flavor;

[0062] Step 1: Wash the fresh white fungus soaked for 1-2 hours with clean water, remove the ear shells, filter the surface water, weigh them, and cut them into 2-3 cm small pieces for later use. Put the cleaned fruits into a dicing machine and cut them into pieces About 0.2cm granular small pieces, weighed for later use, kudzu root powder is ground to obtain kudzu root powder, and water is mixed with a kudzu root slurry in a mass ratio of 5:5;

...

Embodiment 3

[0069] The technological preparation step of white fungus juice drink sauce is carried out according to the following steps:

[0070] Raw material formula: 30 kg of soaked fresh white fungus, (7 parts of strawberries, 3 parts of red dates) 280 kg in total, 10 kg of rock sugar, 110 kg of sucrose, 6 kg of honey, 0.2 kg of kudzu root, 1.8 kg of sodium dihydrogen phosphate, 0.2 kg of citric acid, 1.8 kg of sodium D-erythorbate, 0.012 kg of pectinase, 0.08 kg of cellulase, 0.025 kg of glucose oxidase, 1.2 kg of food flavor;

[0071] Step 1: Wash the fresh white fungus soaked for 1-2 hours with clean water, remove the ear shells, filter the surface water, weigh them, and cut them into 2-3 cm small pieces for later use. Put the cleaned fruits into a dicing machine and cut them into pieces About 0.2cm granular small pieces, weighed for later use, kudzu root powder is ground to obtain kudzu root powder, and water is mixed with a kudzu root slurry in a mass ratio of 5:5;

[0072]Step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com