Organic waste gas purification adsorbent and preparation method thereof

A technology of organic waste gas and adsorbent, applied in chemical instruments and methods, gas treatment, other chemical processes, etc., can solve the problems of high cost and insignificant adsorption effect, and achieve the effect of reducing dosage, good adsorption effect and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

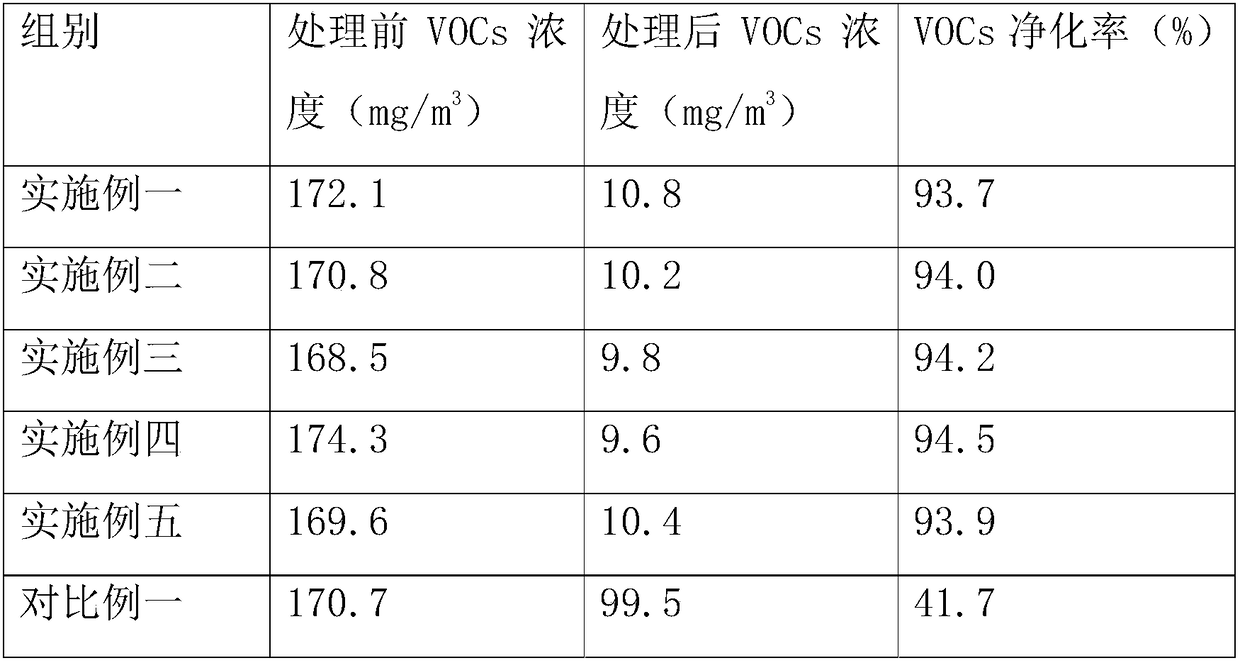

Examples

Embodiment 1

[0030] The adsorbent for purifying organic waste gas provided in this example, the raw materials of the adsorbent include the following components in parts by weight: 120 parts of lipase liquid, 50 parts of coconut shell charcoal, 20 parts of diatomaceous earth, 13 parts of shell powder, expansion 10 parts of graphite, 6 parts of zeolite powder, 5 parts of attapulgite powder, 5 parts of bentonite, 6 parts of ramie fiber, 4 parts of loofah fiber.

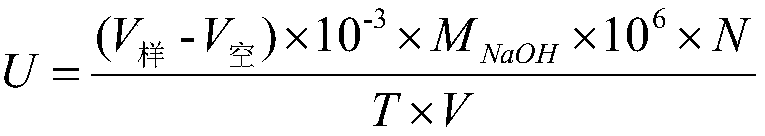

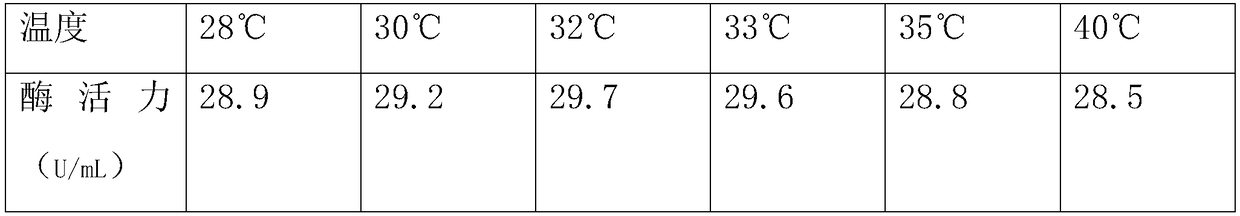

[0031]In the present embodiment, the lipase liquid is the lipase liquid secreted by inoculation of Pseudomonas aeruginosa and yeast in the culture medium in a ratio of 2:1; the total inoculation of the Pseudomonas aeruginosa and yeast The amount is 12% of the medium volume of fermentation culture (referring to the total inoculum volume of Pseudomonas aeruginosa and yeast is 12% of the volume of medium volume of fermentation culture); °C, the rotation speed of the shaker was 150r / min, and the incubation time was 7 days.

[0032] In t...

Embodiment 2

[0042] The adsorbent for purifying organic waste gas provided in this example, the raw materials of the adsorbent include the following components in parts by weight: 135 parts of lipase liquid, 52 parts of coconut shell charcoal, 21 parts of diatomaceous earth, 14 parts of shell powder, expansion 11 parts of graphite, 7 parts of zeolite powder, 6 parts of attapulgite powder, 6 parts of bentonite, 7 parts of ramie fiber, and 6 parts of loofah fiber.

[0043] In the present embodiment, the lipase liquid is the lipase liquid secreted by inoculation of Pseudomonas aeruginosa and yeast in the culture medium in a ratio of 2:1; the total inoculation of the Pseudomonas aeruginosa and yeast The amount is 12% of the medium volume of fermentation culture (referring to the total inoculum volume of Pseudomonas aeruginosa and yeast is 12% of the volume of medium volume of fermentation culture); °C, the rotation speed of the shaker was 150r / min, and the incubation time was 7 days.

[0044]...

Embodiment 3

[0048] The adsorbent for purifying organic waste gas provided in this example, the raw materials of the adsorbent include the following components in parts by weight: 145 parts of lipase liquid, 50 parts of coconut shell charcoal, 22 parts of diatomaceous earth, 13 parts of shell powder, expansion 12 parts of graphite, 6 parts of zeolite powder, 7 parts of attapulgite powder, 5 parts of bentonite, 8 parts of ramie fiber, and 4 parts of loofah fiber.

[0049] In the present embodiment, the lipase liquid is the lipase liquid secreted by inoculation of Pseudomonas aeruginosa and yeast in the culture medium in a ratio of 2:1; the total inoculation of the Pseudomonas aeruginosa and yeast The amount is 12% of the medium volume of fermentation culture (referring to the total inoculum volume of Pseudomonas aeruginosa and yeast is 12% of the volume of medium volume of fermentation culture); described mixed fermentation culture condition is: culture temperature is 35 °C, the rotation sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com